Cotton stripping roller support plate of a carding machine

A technology for carding machines and pallets, which is applied to deburring devices, textiles and papermaking, and fiber processing. It can solve problems such as cumbersome operations, low equipment operation efficiency, and impact on production, so as to improve the quality of sliver and reduce labor. Strength, the effect of improving equipment operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

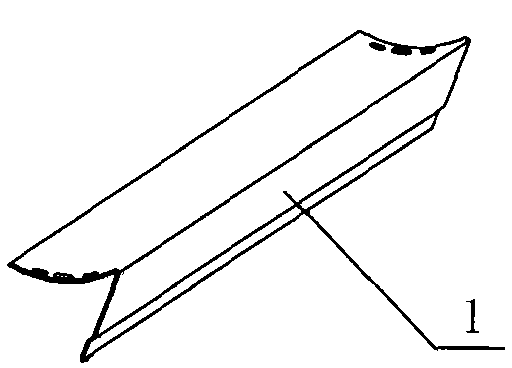

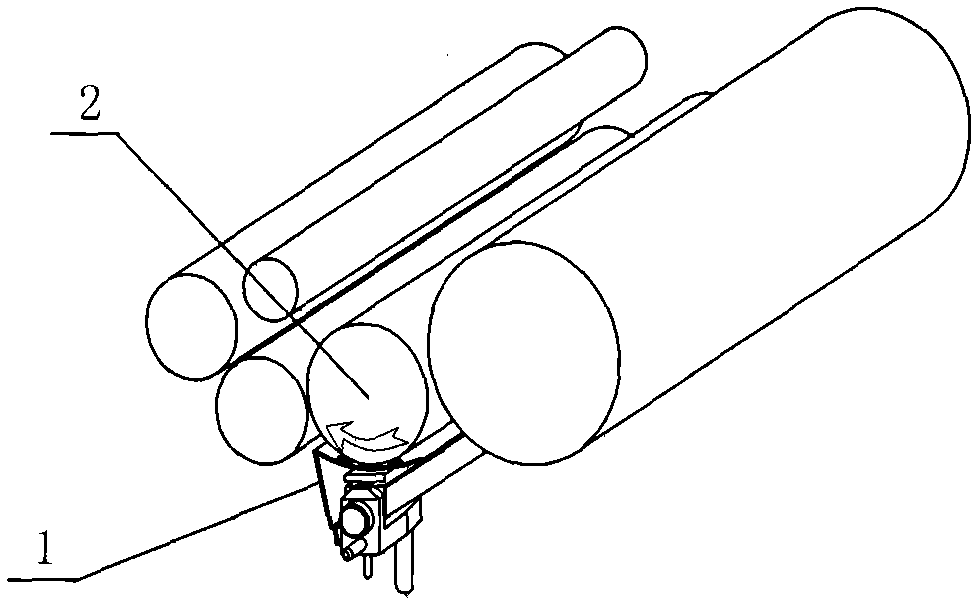

[0012] see figure 1 , figure 2 , the stripping roller supporting plate of former carding machine is arc smooth surface supporting plate 1, is directly installed in the stripping roller 2 below by fixing screw, and the distance between arc supporting plate 1 and stripping roller 2 is very little.

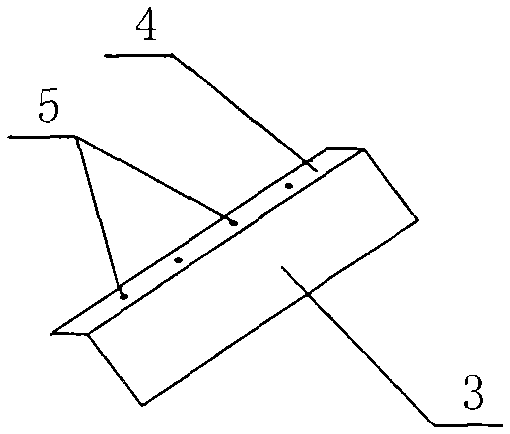

[0013] combine image 3 , Figure 4 , Figure 5 Visible, the stripping roller supporting plate of carding machine of the present invention is made up of wide plate 3 and narrow plate 4 two parts, is downward 135 degree included angles between wide plate 3 and narrow plate 4, in the narrow plate 4 of supporting plate There are 4 small holes 5 horizontally on the top, and 4 holes with internal threads corresponding to the positions of the above-mentioned small holes are provided at the bottom of the doctor blade device 7 located below the lower roll 6, and the narrow plate 4 of the supporting plate is fixed on the Below the scraper blade device 7.

[0014] The processing method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com