Active feeding conducting bar device of gill box

A needle carding machine and sliver guide technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of detailed velvet formation, loose velvet structure, and less fiber curling, etc., to achieve Improve sliver quality, eliminate friction, loose structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

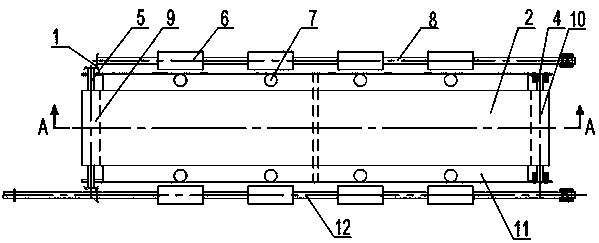

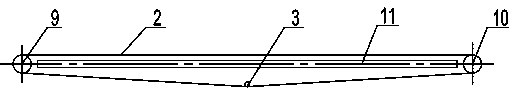

[0012] like figure 1 , figure 2 As shown, a kind of active feeding guide device of a needle carding machine, comprising: a guide platform 11, one side of the guide platform 11 is provided with an active feeding guide roller shaft 8 driven by a motor drive device, and the guide platform 11 The other side is provided with a driven feed guide roller shaft 12, and several feed guide rollers 6 are arranged on the active feed guide roller shaft 8 and the driven feed guide roller shaft 12. The quantity of guide roller 6 can be set according to the length of guide strip platform 11, and one end of guide strip platform 11 is provided with driving side shaft 5, and driving side shaft 5 is provided with driving roller 9, and the two ends of described driving side shaft 5 are respectively It is connected with the active feeding guide roller sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com