Reciprocating disc picking device for textile production

A reciprocating and disc technology, which is applied in textiles and papermaking, unpacking with beaters, fiber treatment, etc., can solve the problems affecting the effect of grasping cotton raw materials, affecting the efficiency of cotton raw materials grasping cotton, increasing the labor intensity of personnel, etc., to achieve Improve the efficiency of picking cotton, shorten the time of picking cotton, reduce the difficulty of operation and the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

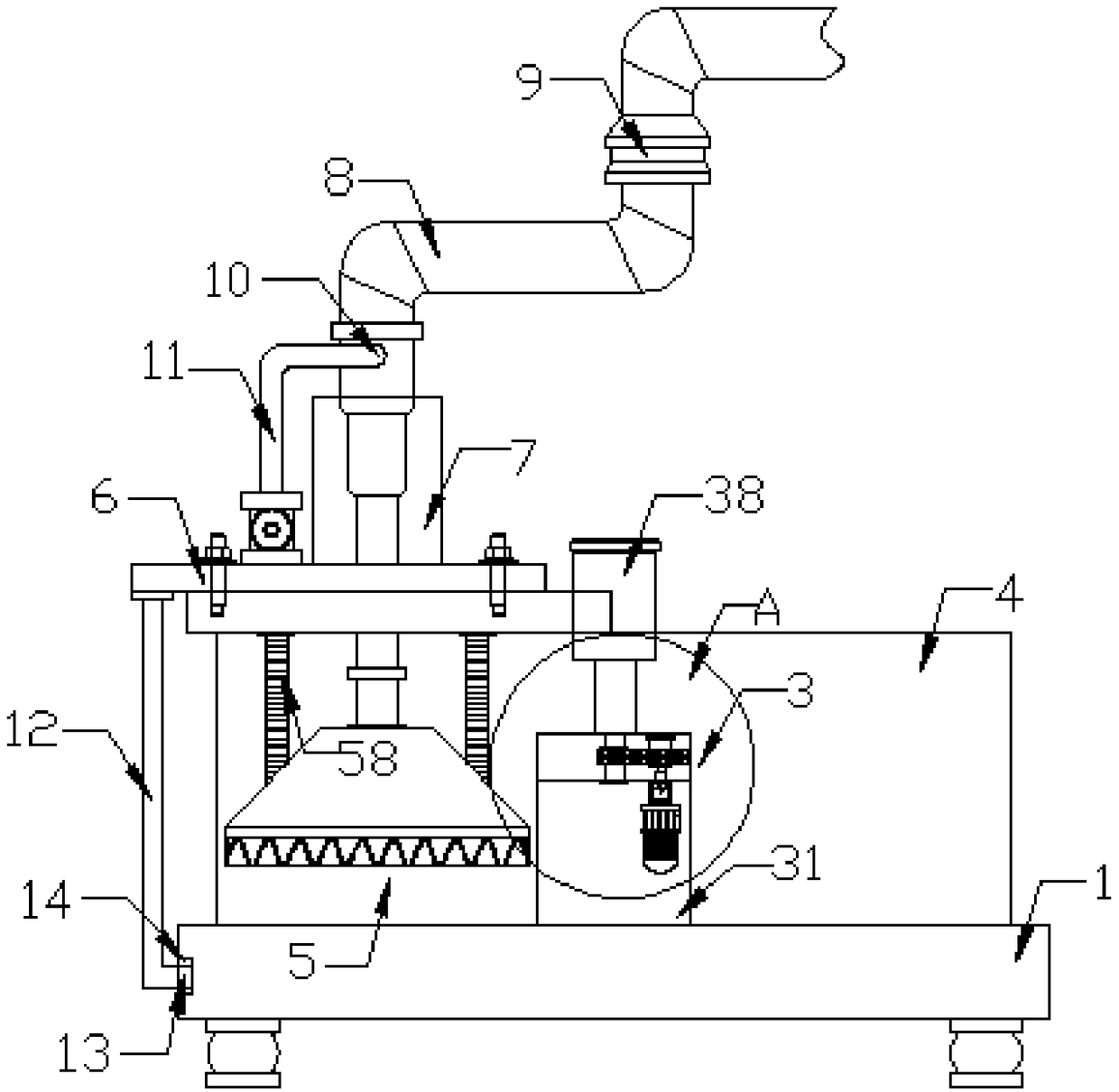

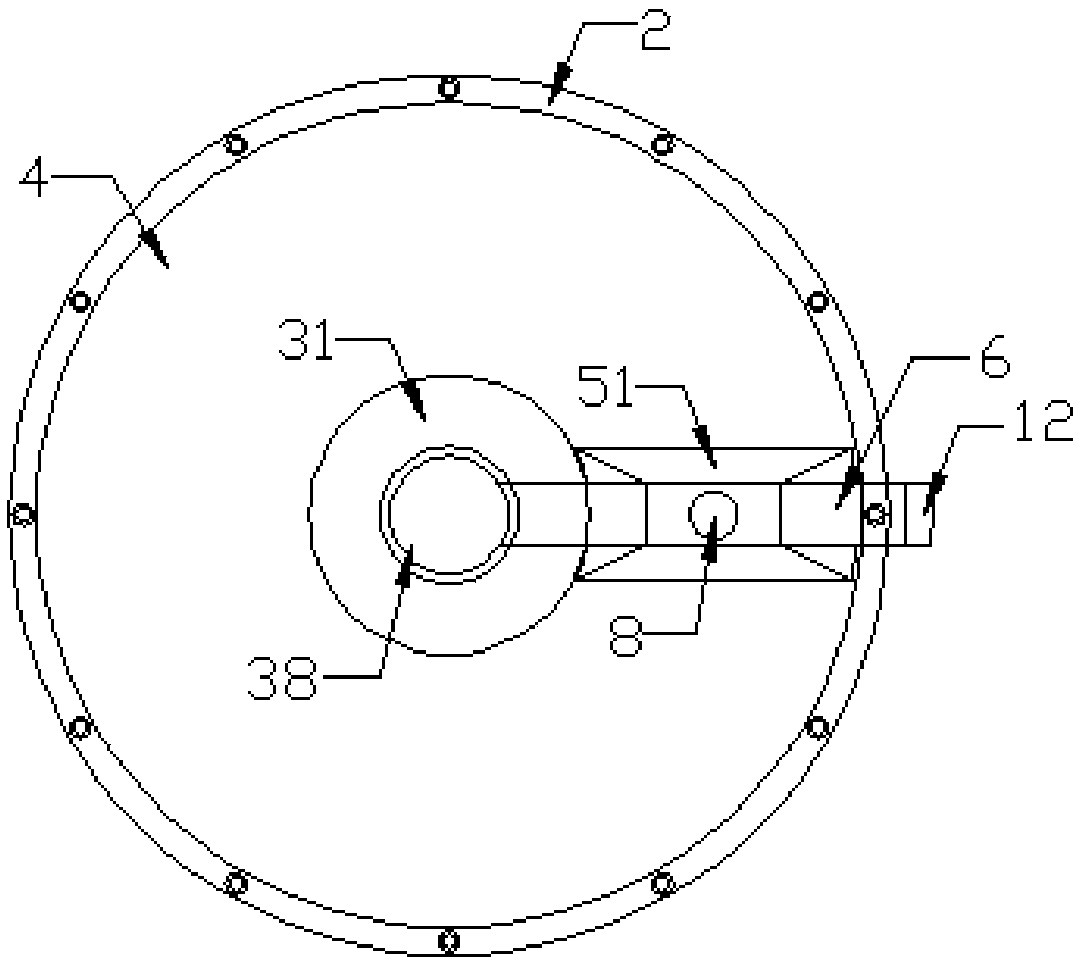

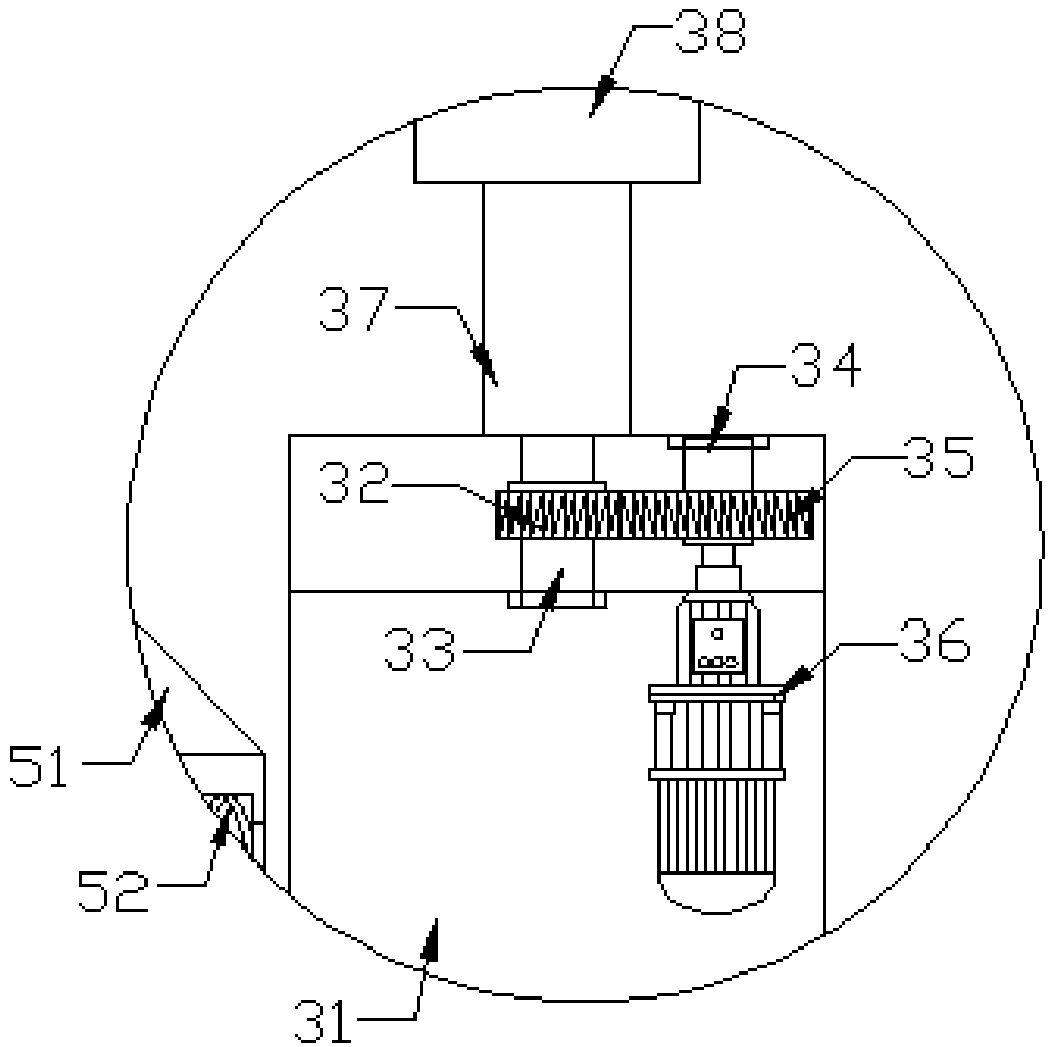

[0022] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a reciprocating disc cotton grabbing device for textile production, including a bearing base 1, a circular side baffle 2, a cotton grabbing driving mechanism 3, and an annular cotton grabbing track 4 , walking and grasping cotton mechanism 5, turret 6, cotton guide pipe 8, external air pipe 11, connecting frame 12 and circular slide rail 14, the top of the bearing base 1 is equipped with an annular side baffle 2, the A cotton grabbing driving mechanism 3 is fixedly installed on the bearing base 1 at the center of the inner center of the circular side baffle 2, and an annular cotton grabbing track 4 is formed between the cotton grabbing driving mechanism 3 and the circular side baffle 2 , the inside of the annular grabbing track 4 is provided with a walking grabbing mechanism 5, a turret 6 is installed on the top of the walking grabbing mechanism 5, and a supporting frame 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com