Manufacturing method of pure cotton non-additive soft knitted fabric

A manufacturing method and technology of knitted fabrics, which are applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of affecting the wearing experience, not being energy-saving and environmentally friendly, and not being energy-saving and environmentally friendly, so that it is not easy to break holes, takes less time, and is tidy good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for making all-cotton soft knitted fabrics without additives, comprising the following steps:

[0044] S1. Yarn spinning process, spinning fine-staple cotton above 129 into yarn.

[0045] S10. In the process of opening and cleaning cotton, the distance between the beater and the dust bar is adjusted to reduce cotton waste, and the impurity removal rate is controlled at 5%.

[0046] S11. In the carding process, the noil rate is controlled at 10% by adjusting the gauge.

[0047] S12. The speed of the combing process is controlled at 450 inserts / min, the noil rate is controlled at 5%, and the evenness value CV is below 5%.

[0048] S13. The speed of the drawing process is 800m / min, and the CV value of the sliver weight is 3%.

[0049] S14. Twist to Z twist in the roving process, the twist coefficient is 110, the flyer speed is 960r / min, and the total draft ratio is 39 times.

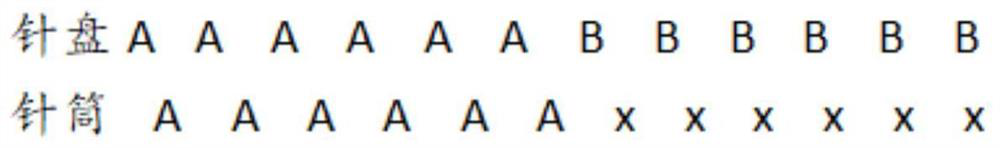

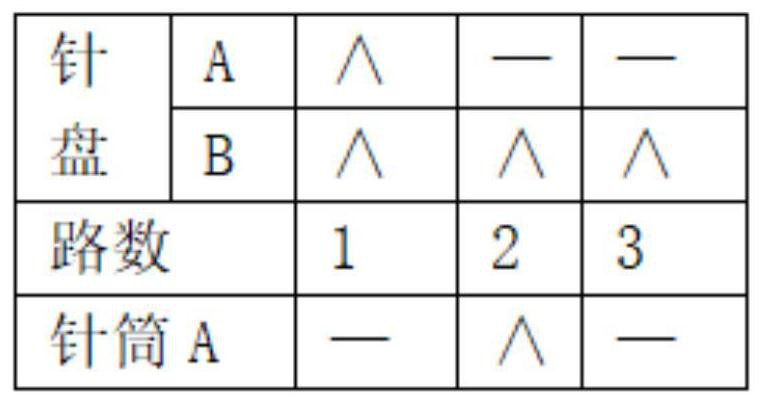

[0050] S15. Twist to S twist in spinning process, twist coefficient is 220, reverse y...

Embodiment 2

[0059] A method for manufacturing all-cotton soft knitted fabrics without additives, comprising the following steps in sequence:

[0060] S1, yarn spinning process, the fine-staple cotton above 129 and the long-staple cotton above 133 are mixed and spun into yarn.

[0061] S10. In the process of opening and cleaning cotton, the distance between beaters and dust rods is adjusted to reduce cotton waste, and the impurity removal rate is controlled at 10%.

[0062] S11. In the carding process, the noil rate is controlled at 15% by adjusting the gauge.

[0063] S12. The speed of the combing process is controlled at 500 inserts / min, the noil rate is controlled at 10%, and the evenness value CV is below 5%.

[0064] S13. The speed of the drawing process is 1000m / min, and the CV value of the sliver weight is 5%.

[0065] S14. Twist to Z twist in the roving process, the twist coefficient is 130, the flyer speed is 1000r / min, and the total draft ratio is 52 times.

[0066] S15. S-twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com