A New Cotton Grabbing Technology Applicable to Intelligent Spinning

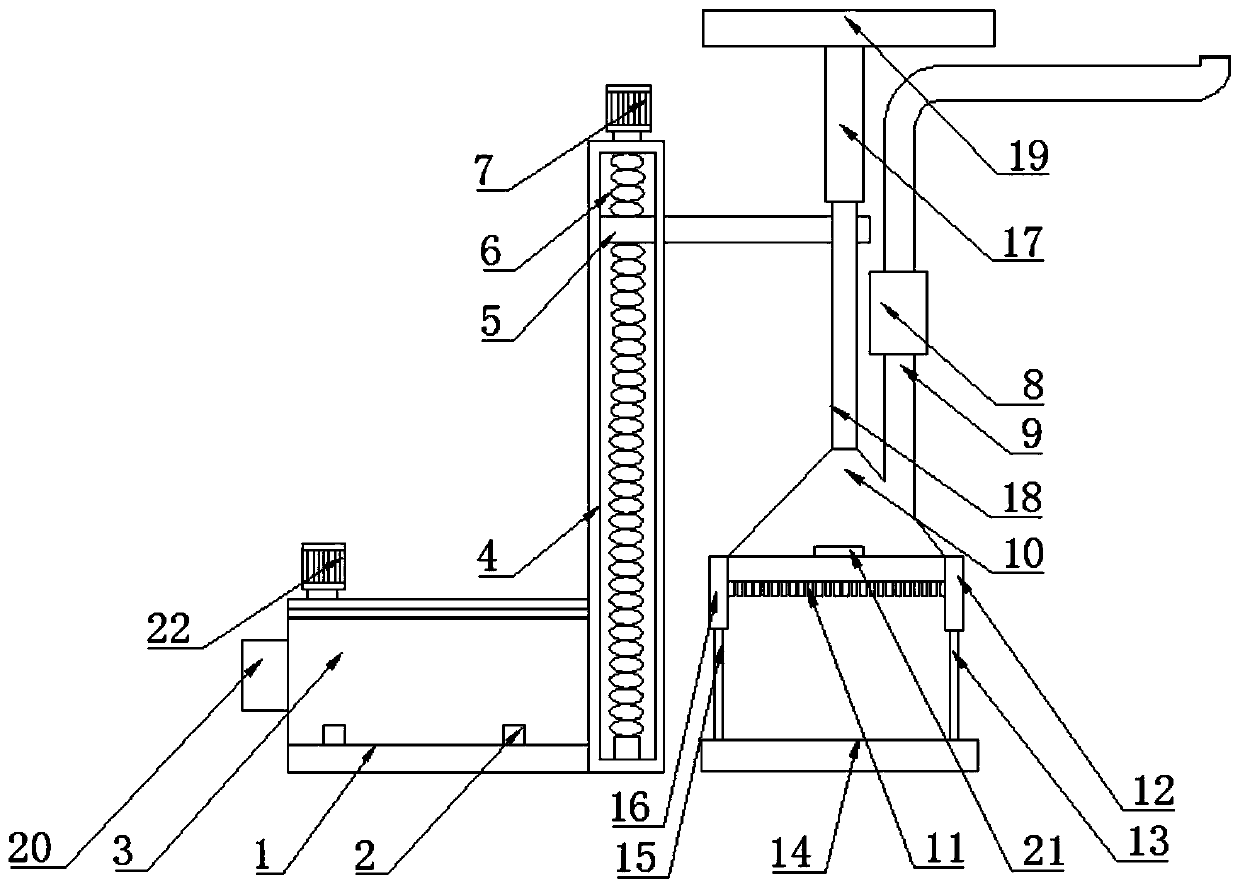

A technology of intelligent spinning and craftsmanship, which is applied in the directions of unpacking with beaters, optical devices, instruments, etc., can solve the problem that raw materials are easy to fall on the outside of the cotton grabbing platform, save manpower and material resources, and facilitate the grasping of raw materials and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A new cotton picking process suitable for intelligent spinning, comprising the following steps:

[0042] S1. Unloading on the catching workbench: During the operation of the cotton catching device of intelligent spinning, feed raw materials to the catching cotton workbench;

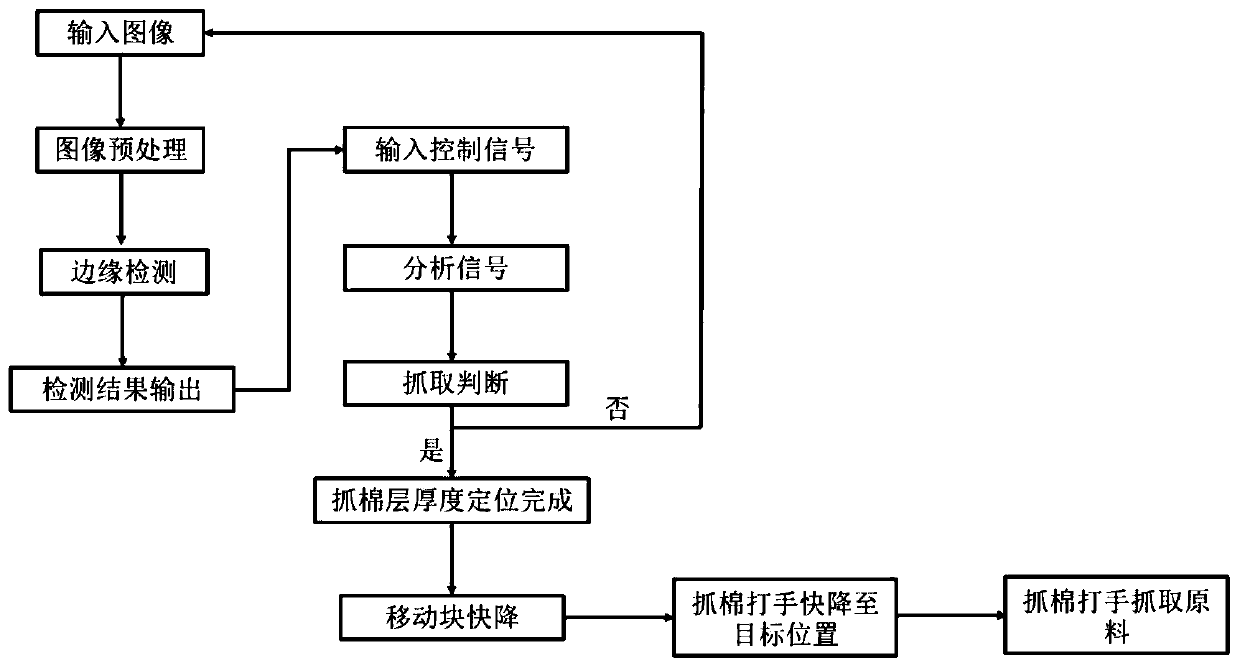

[0043] S2. Send out a signal for cotton: the cotton catching machine turns on the automatic cotton catching mode, calculates the thickness of the cotton layer through image recognition software, calculates the distance and speed of the cotton catching beater, and the cotton catching beater automatically reciprocates through the lifting and moving device to run the cotton picking program;

[0044] S3. Feeding: the cotton catcher grabs the raw materials and transports them through the feeding air duct.

[0045] Further, in the step S2, in the process of catching cotton, the direction of the instantaneous speed of the lowest point of the cotton catching beater is opposite to the running speed directio...

Embodiment 2-5

[0066] Embodiments 2-5 provide a new cotton-catching process suitable for intelligent spinning. Compared with Example 1, the difference is that the rotating speed of the cotton-catching beater is changed. Except for the above differences, other operations are the same. No more details here, the specific parameters are shown in Table 1.

[0067] Table 1:

[0068]

[0069] It can be seen from Table 2 that with the increase of the speed of the cotton picker, the short-lint rate shows a gradually increasing trend. This is mainly because, as the speed of the cotton picker increases, the gear blade on the cotton picker The cotton is hit and torn more violently, and the degree of damage to the fiber is increased, which in turn increases the amount of short-lint formed in the process of picking cotton. Low, so in order to increase the output of cotton picking and reduce the formation of short fibers, the cotton picking performance is better when the cotton picking speed is 900-140...

Embodiment 6-10

[0071] Embodiments 6-10 provide a new cotton picking process suitable for intelligent spinning. Compared with Example 1, the difference is that the diameter of the cotton picking beater is changed. Except for the above differences, other operations are the same. No more details are given here, and the specific parameters are shown in Table 2.

[0072] Table 2:

[0073] Example Cotton beater diameter (mm) Short fiber rate Example 6 200 10.5% Example 7 250 11.7% Example 8 275 13.9% Example 9 300 14.3% Example 10 350 19.6%

[0074] It can be seen from Table 3 that with the increase of the cotton picking diameter, more blades can be arranged on the cotton picking beater, the longer the arc length, the larger the working area, and the greater the grasping output during the cotton picking process , the greater the tearing frequency of cotton grabbers per unit time, the higher the short-lint rate is. When the diameter of grab cott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com