Carding machine with dust removing function

A carding and functional technology is applied in the field of cards with dust removal function, which can solve the problems of cotton debris splashing, dust raising, and the inability of dust removal to achieve a good effect, and achieve the effect of improving the dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

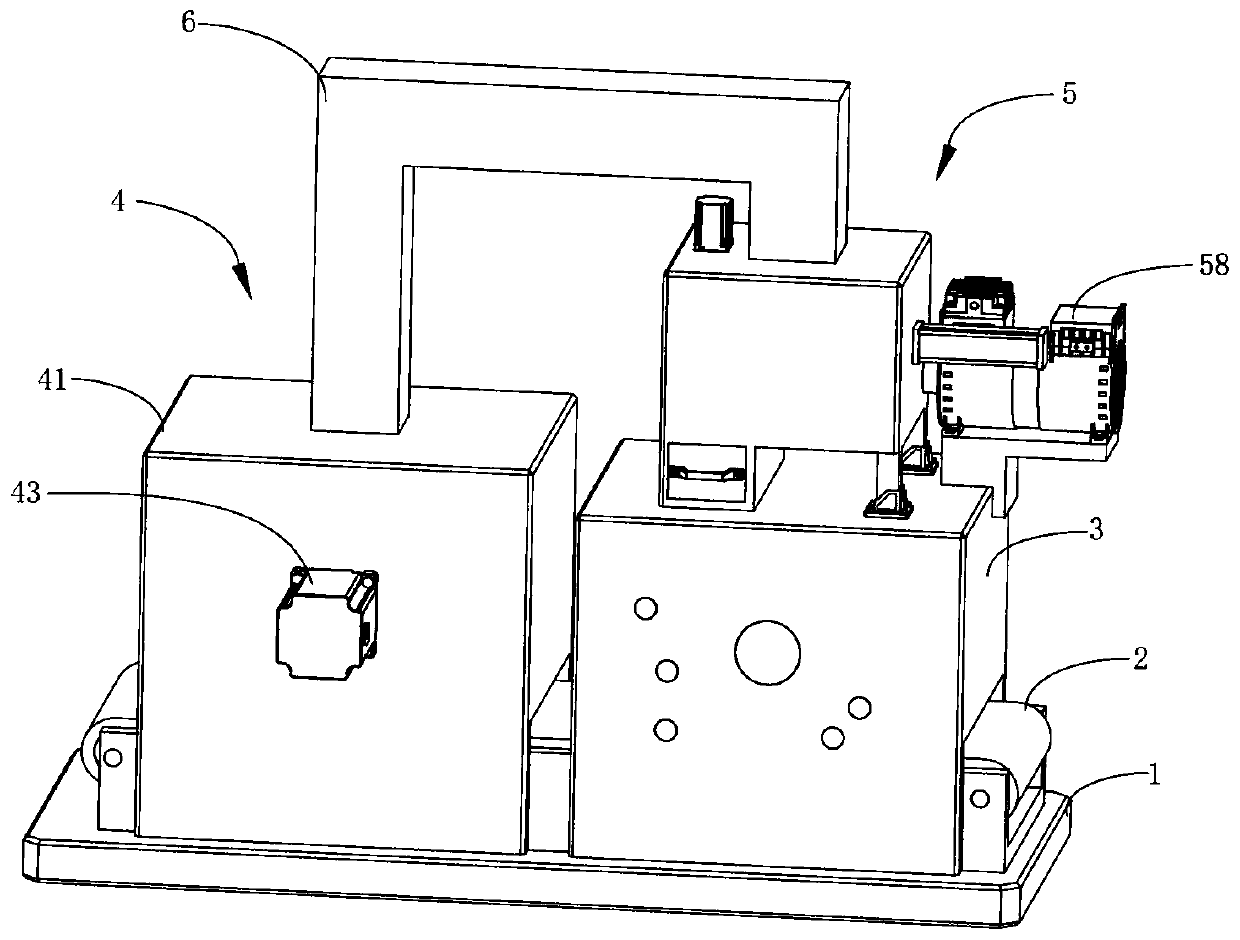

[0024] see Figure 1 to Figure 5 , the present invention provides a technical solution:

[0025] A carding machine with dust removal function, comprising a frame 1, a conveyor belt 2, a carding machine 3, a dust raising mechanism 4, a dust removal mechanism 5 and a square tube 6, the conveyor belt 2 is fixedly installed on the frame 1, and the carding machine 3 is fixedly installed on the frame 1 and located above the conveyor belt 2, where:

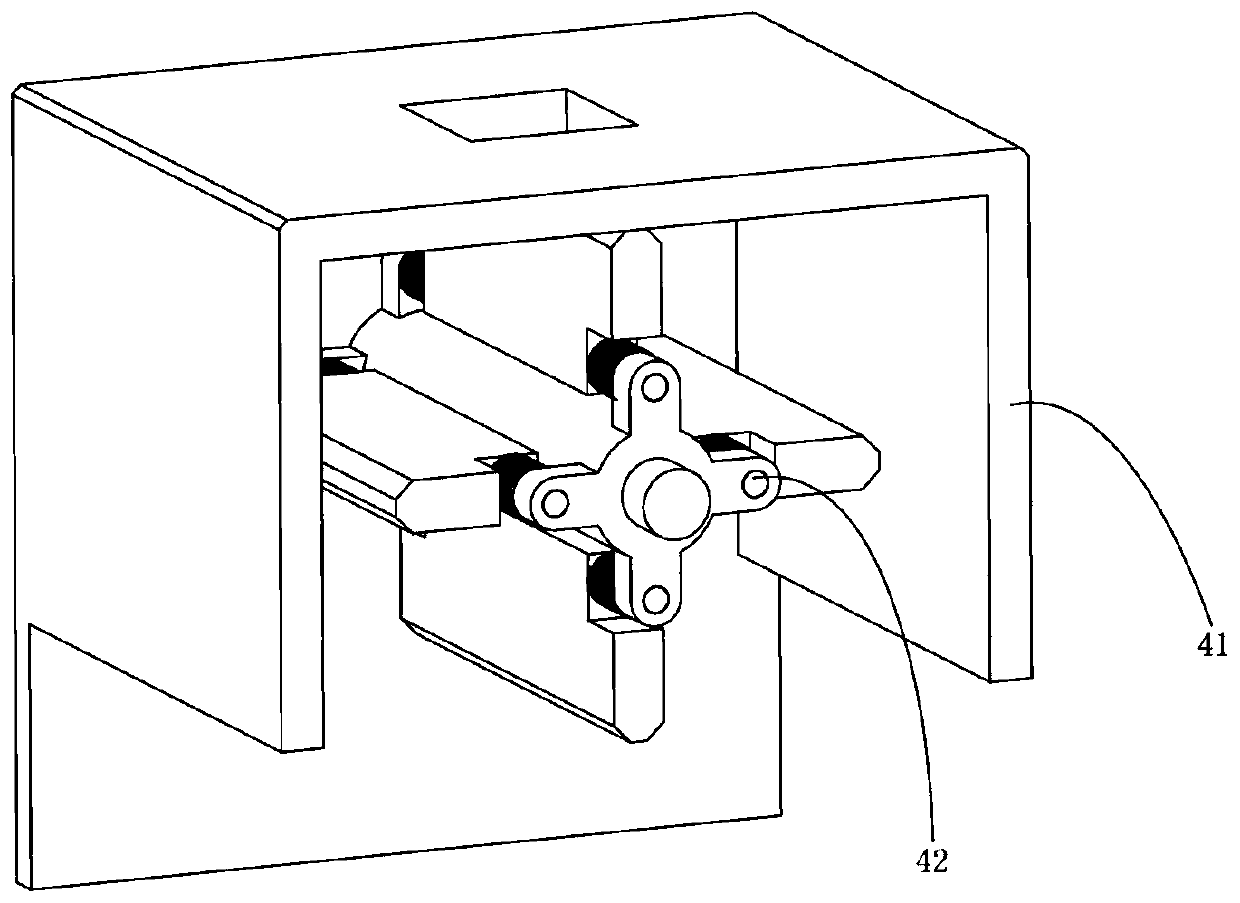

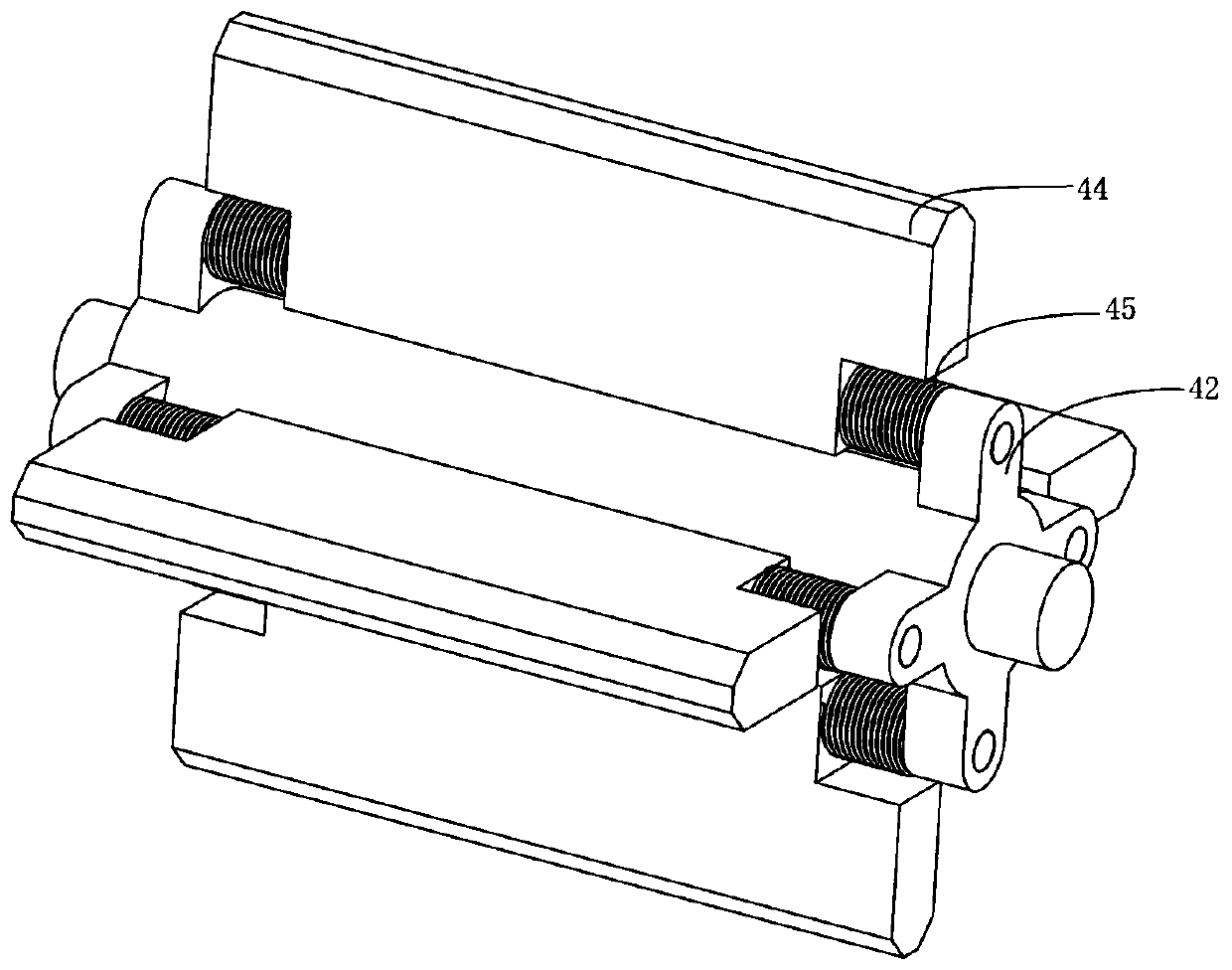

[0026] The dust-raising mechanism 4 includes a dust-raising box 41, a support frame 42, a motor I 43, a beating plate 44 and a torsion spring 45. The dust-raising box 41 is fixedly installed on the frame 1 and is located above the conveyor belt 2, and the two ends of the support frame 42 pass through bearings respectively. Rotationally installed in the dust box 41, the motor I43 is fixedly installed on the dust box 41 by bolts, the power output end of the motor I43 is fixedly connected with the support frame 42, and several beating plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com