A material automatic cleaning device

An automatic cleaning and material technology, used in kitchen utensils, home utensils, cooking utensils, etc., can solve problems such as poor separation of dirt and dust, and achieve the effect of improving surface quality, maintaining nutrients and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

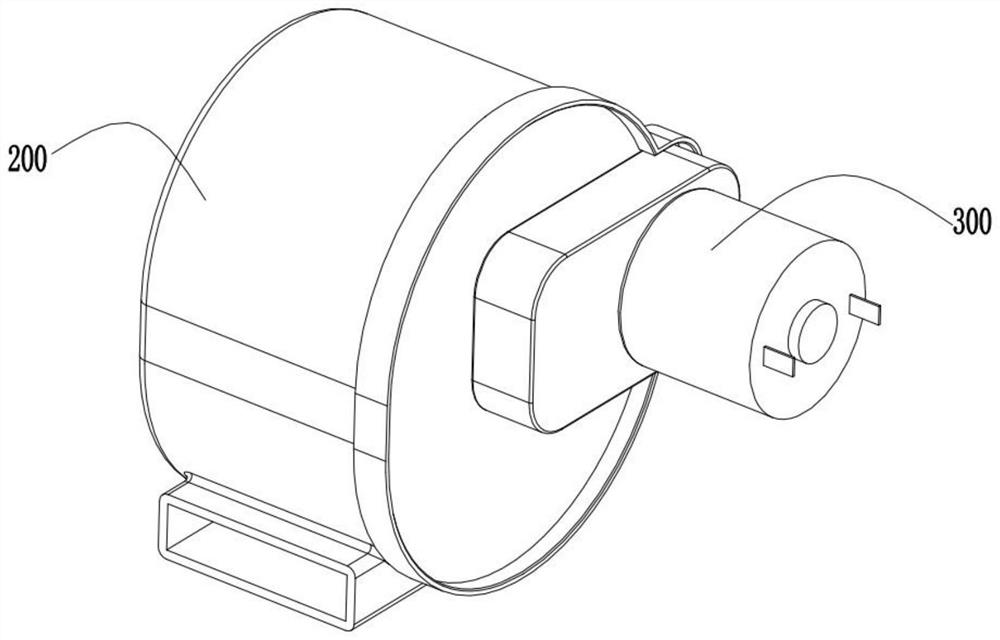

[0033] In this embodiment, if figure 1 As shown, it is an automatic material cleaning device for cleaning materials. The materials can be whole grains, beans and other materials, such as rice, black rice, glutinous rice, millet, corn, soybeans, red beans, mung beans, etc. This material is automatically cleaned. The cleaning device can be used together with the cooking utensils to provide clean and hygienic materials for the cooking utensils. At the same time, the material automatic cleaning device can also be used alone to complete the automatic cleaning of materials and save manpower and material resources.

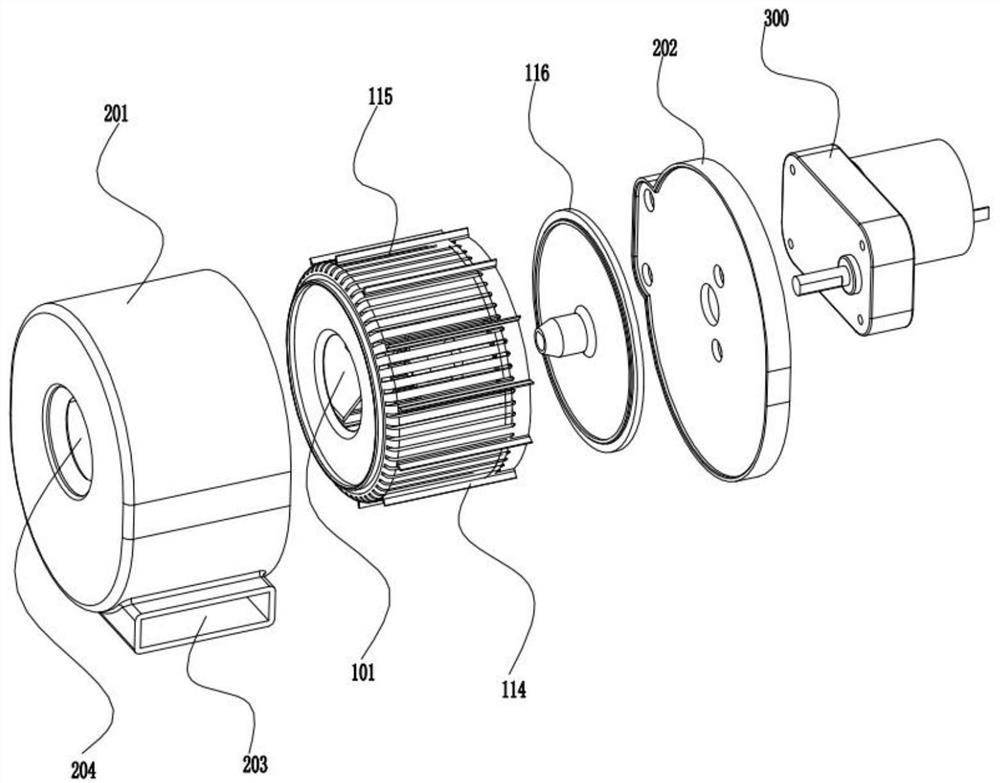

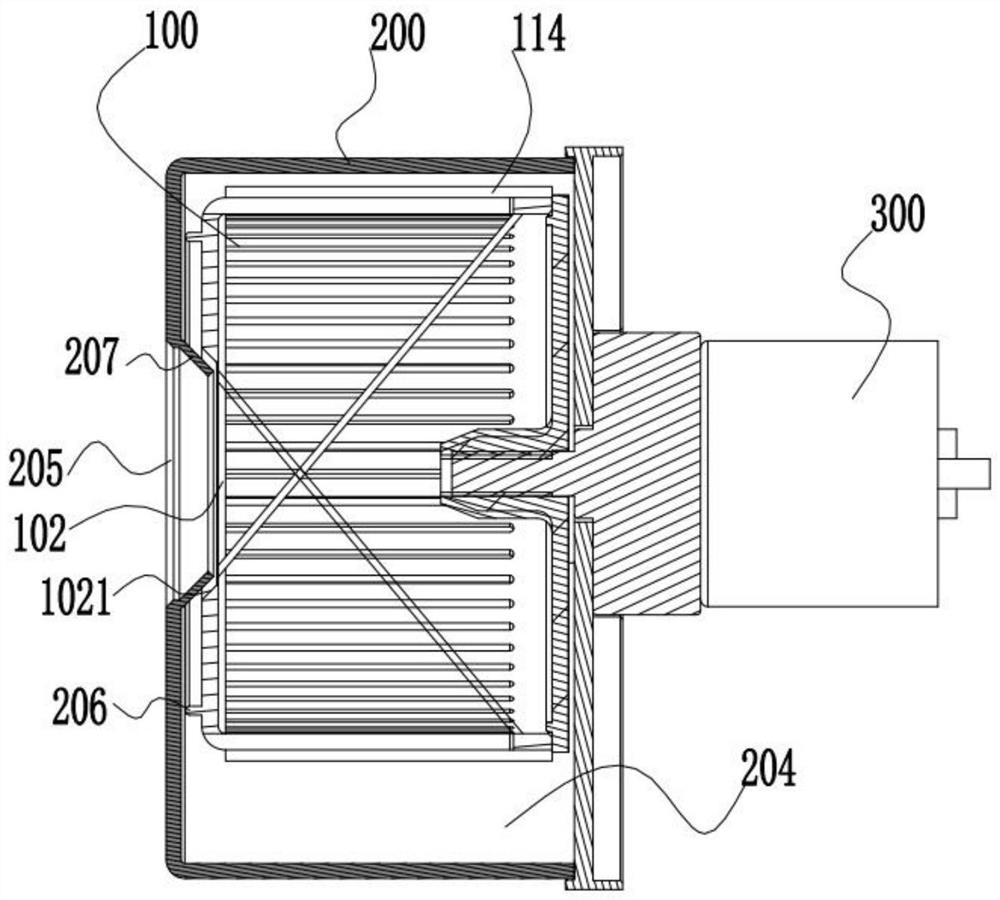

[0034] Such as figure 1 and 3 The material automatic cleaning device shown includes a rotary bin 100 and a dust storage bin 200. The rotary bin 100 is arranged in the dust storage bin 200 and can rotate in the dust storage bin. The rotary bin is provided with a cleaning chamber for storing materials, and at the same time Also be provided with the material mouth 102 tha...

Embodiment 2

[0064] Such as Figure 11 As shown, in this embodiment, there is no turning vane in the cleaning chamber, and the turning of the material is realized by using the cleaning chamber itself. When the turning vane is not set in the cleaning chamber, the shape of the rotating bin is preferably polygonal, and the material can be turned over at this time. It is more complete and fully raised to prevent accumulation. When the turning blade is not installed, the material can be discharged from the material port by dumping. Of course, the material port can also be set as a feed port or a discharge port. The feed port can be set at the front of the rotary bin, and the discharge port can be set at The side wall, and the discharge port is blocked by the plugging structure in the cleaning state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com