Seed cotton foreign fiber separating and opening machine

A kind of foreign fiber and opener technology, which is applied in the direction of fiber opening and cleaning machines and suction devices, which can solve the problems of increasing the difficulty of impurity removal, increasing production and manufacturing costs, and high labor intensity, so as to prevent the seed cotton fiber Effects of damage, saving production cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

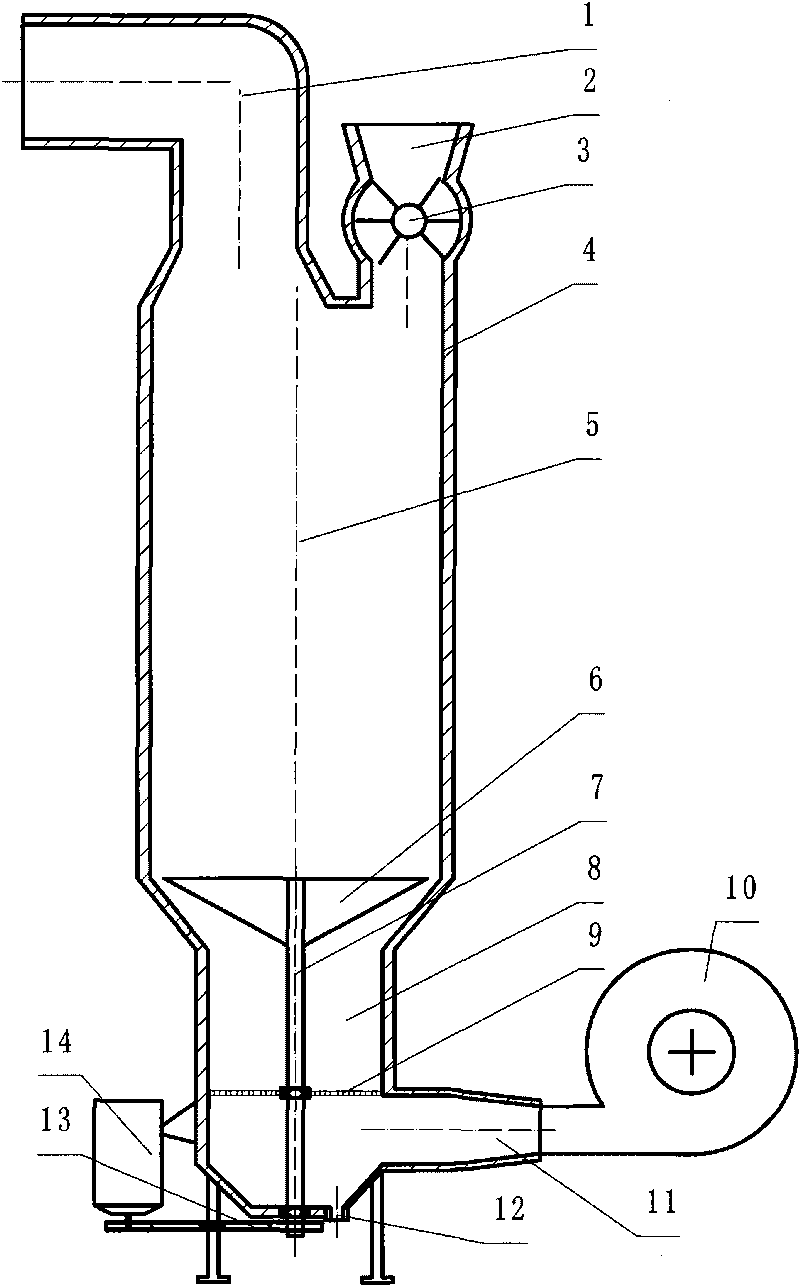

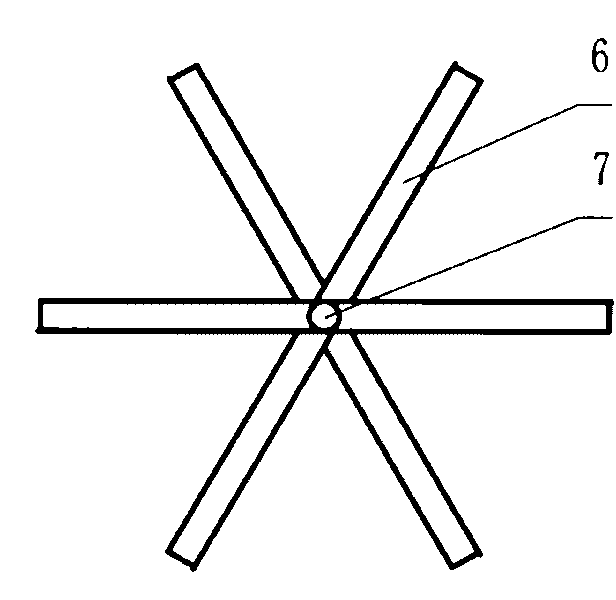

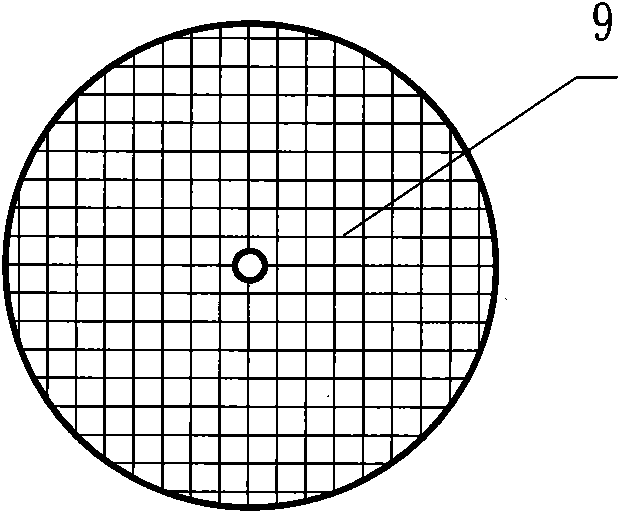

[0021] Refer to attached figure 1 , figure 2 , image 3 , the present embodiment includes a machine housing 4, the upper part of the machine housing 4 is provided with a material inlet 2, a material outlet 1, and the lower part is provided with a miscellaneous discharge port 12, and the inside of the machine housing 4 is composed of upper and lower parts of the cavity The fluidization chamber, the volume of the cavity 5 in the upper part of the fluidization chamber is larger than the volume of the cavity 8 in the lower part of the fluidization chamber. The driving rod 7 at the bottom of the fluidization chamber is composed of the opening plate 6 arranged on the top of the driving rod 7 , and the opening plate 6 is a triangular wing plate evenly distributed on the top of the driving rod 7 . The lower part of the fluidization chamber is provided with an air inlet 11, and the air inlet 11 is connected to the fan 10. The upper part of the fluidization chamber is located at the ...

Embodiment 2

[0023] Compared with Embodiment 1, this embodiment differs in that the air inlet 11 may be provided with a wind regulating valve to adjust the wind force. When the fan 10 blows hot air, the seed cotton can be dried while the seed cotton is loosened, which saves the investment of drying equipment and saves the cost of installing drying equipment elsewhere.

Embodiment 3

[0025] Compared with Embodiment 1, this embodiment is different in that a motor 14 is provided outside the fluidization chamber, and the motor 14 is connected to the lever disperser through a transmission device. The transmission device is a belt transmission, and the driving rod 7 passes through the mesh partition 9 and is fixedly installed at the bottom, and the motor 14 drives the driving rod 7 to rotate through the transmission device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com