Self-cleaning scutcher

A cotton cleaning machine and self-cleaning technology, which is applied in fiber opening and cleaning machines, fiber treatment, fiber opening and cleaning, etc., can solve the problems of cotton clogging and debris cavity entanglement, and achieve easy cleaning, easy detachment, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

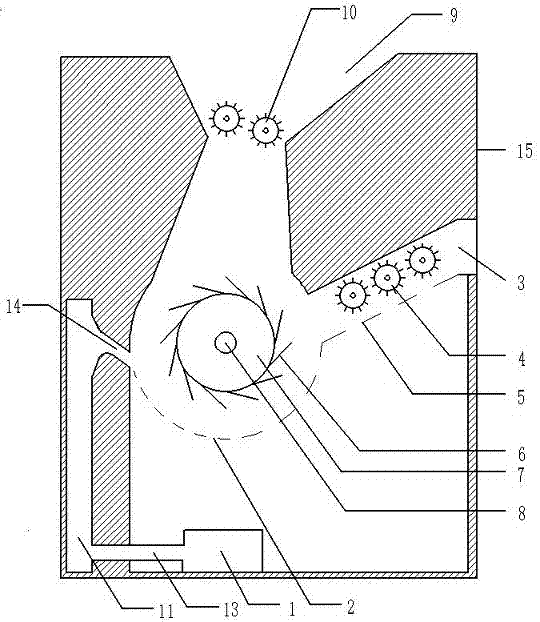

[0021] The reference signs in the drawings of the specification include: fan 1, cotton cleaning baffle 2, outlet channel 3, outlet roller 4, outlet baffle 5, blade 6, cleaning beater 7, central shaft 8, and material inlet 9 , the entrance roller 10, the air duct 11, the air duct 13, the air duct outlet 14, and the shell 15 of the cleaning machine.

[0022] The embodiment is basically as attached figure 1 Shown:

[0023] A self-cleaning cotton cleaning machine, comprising a cotton cleaning machine shell 15, a cavity is arranged in the cotton cleaning machine shell 15, a cotton cleaning baffle 2 with a through hole is arranged in the cavity, and the cleaning baffle 2 separates the cavity into an upper The cotton cleaning chamber and the debris collection chamber below;

[0024] The center of the cleaning chamber is fixed with a central shaft 8, and the central shaft 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com