Cotton batting re-fluff structure

A fluffy and batting technology, which is applied in the field of reprocessing the fluffy structure of old batting, can solve the problems of increased breakage, increase of short fibers, easy generation of flying flowers, etc., and achieve the effect of reducing the production of short fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

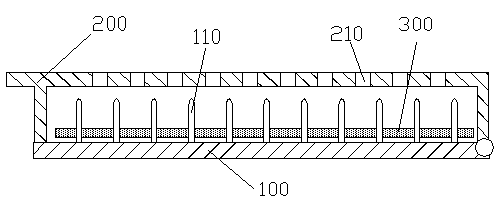

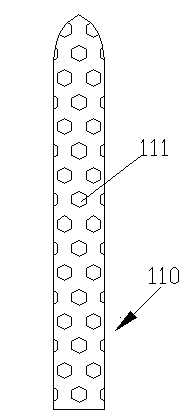

[0017] refer to figure 1 , in this embodiment, the fluffy structure of the cotton wool includes a processing substrate 100, a sealing cover 200 for sealing the processing substrate is hinged on one side of the processing substrate 100, an atomizing nozzle is arranged on the processing substrate 100, and the The atomization nozzle is connected to the Supershenbo atomizer, and the atomization substance of the ultrasonic atomizer is a high-pressure liquid gas, and the high-pressure liquid gas is set in a liquid supply tank with a valve, and the liquid supply tank is connected to a supply station The above-mentioned high-pressure liquid gas compressor, the sealing cover 200 or the processing substrate 100 is provided with a valve body 210 .

[0018] The above-mentioned cotton wool has a fluffy structure, and the high-pressure liquid gas is liquefied nitrogen. The liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com