Device for cleaning fiber wadding

A technology of cleaning equipment and fiber wadding, which is applied in the field of fiber wadding cleaning equipment, can solve the problems of reducing the cleaning efficiency of cleaning equipment, and achieve the effect of high throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

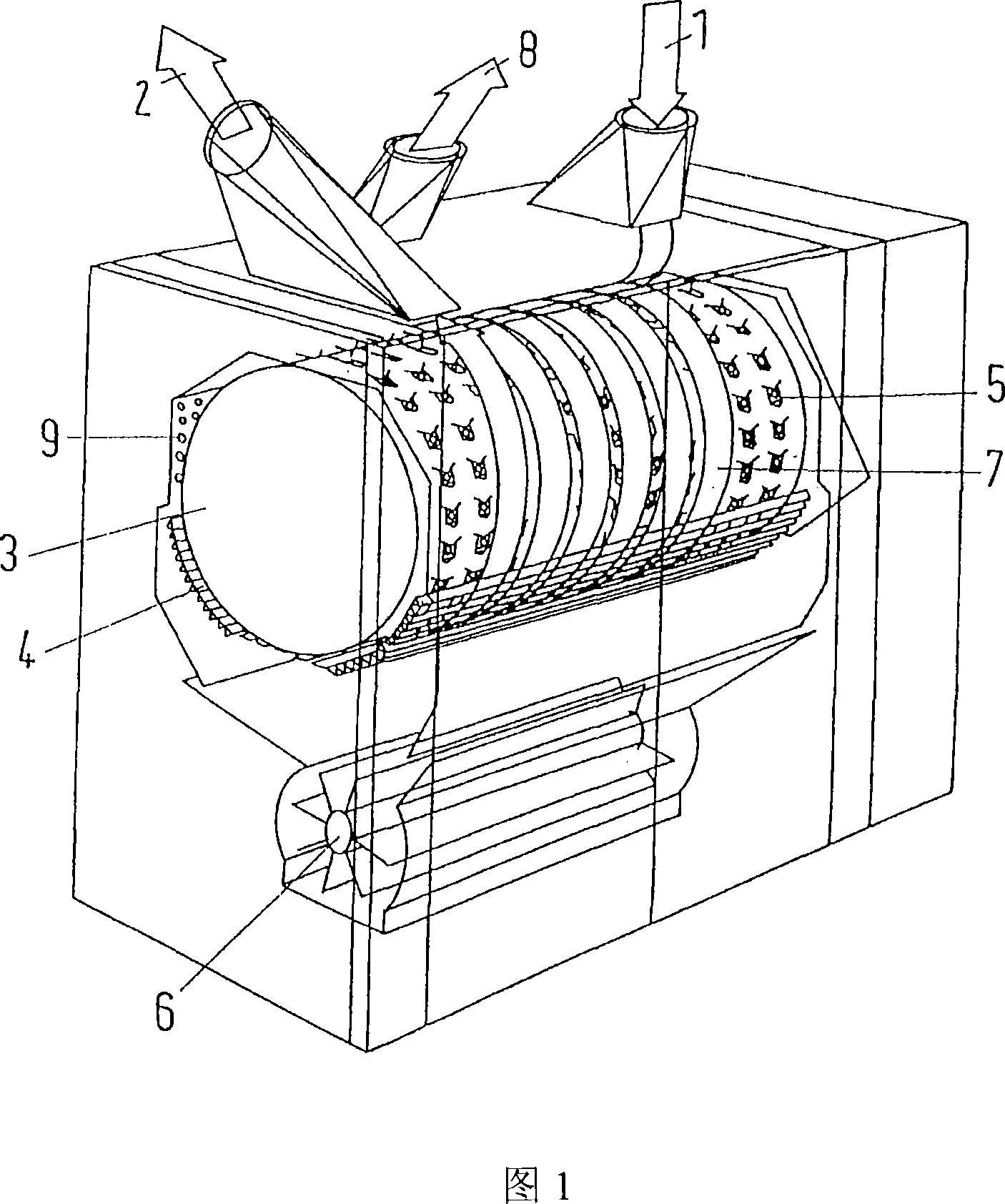

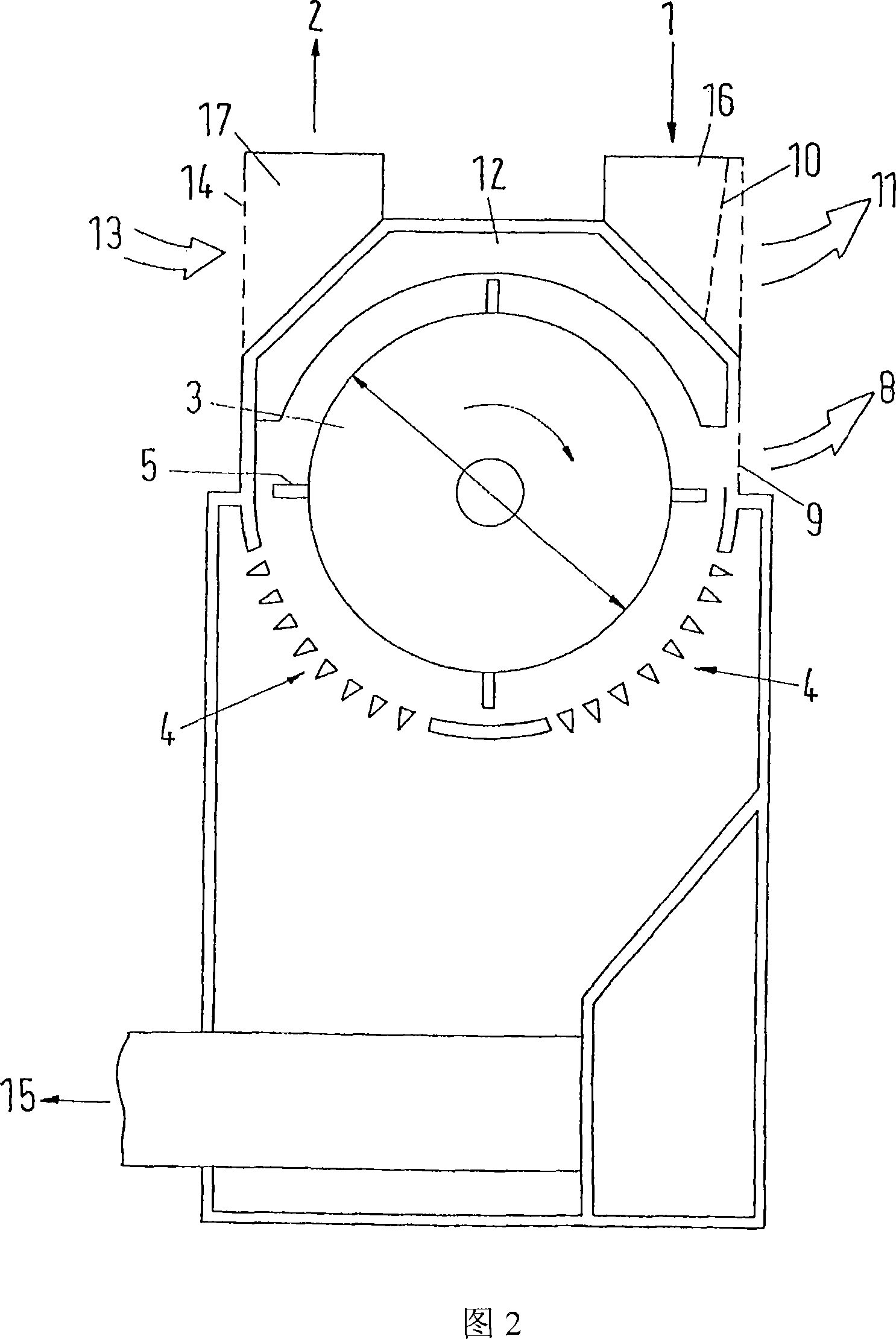

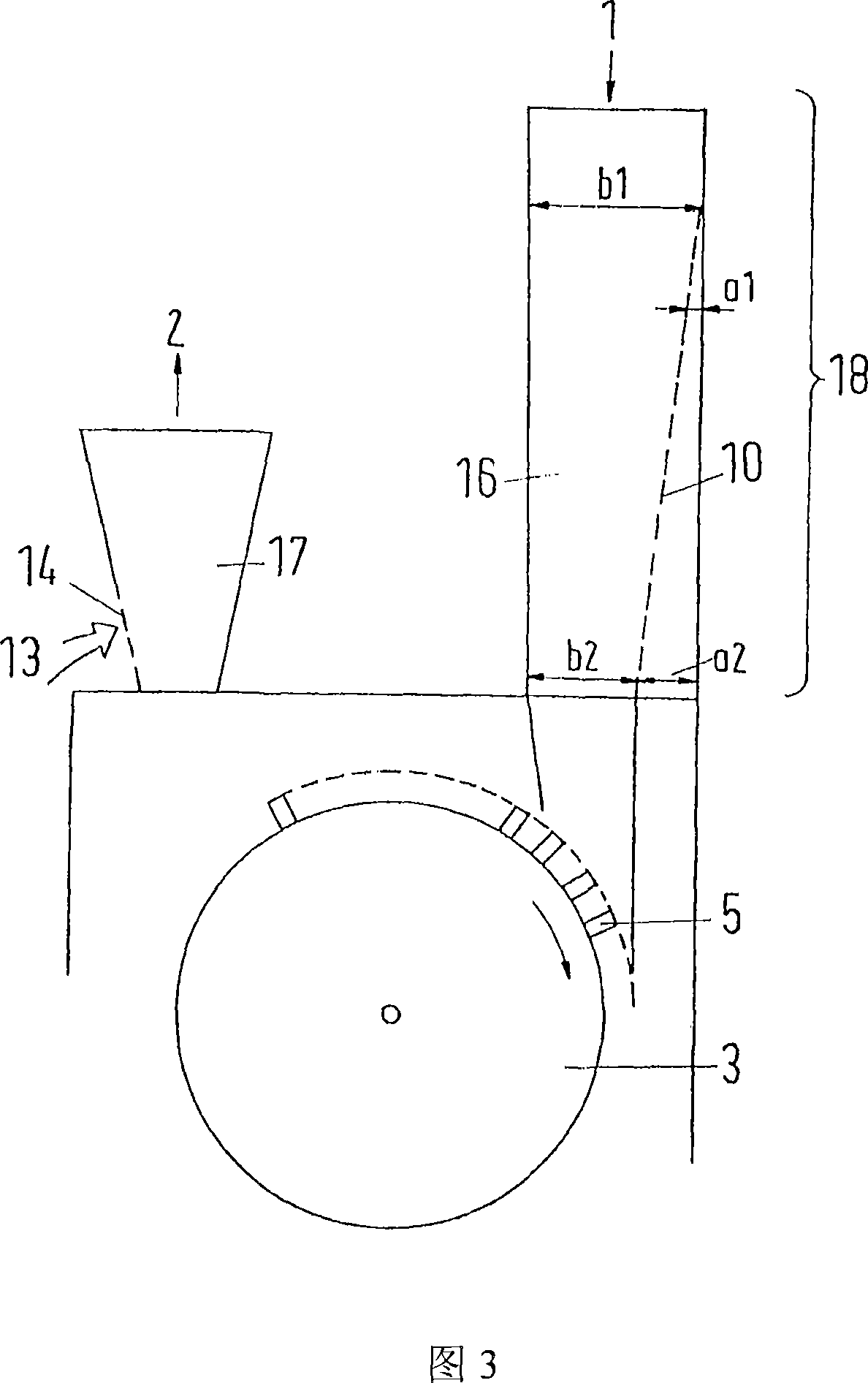

[0022] According to the prior art, a cleaning device is described with reference to FIG. 1 , see also documents EP381860, EP379726 and EP447966, which disclose similar devices in more detail and which form an integral part of the present application. The cleaning device shown in FIG. 1 includes an opening roller 3, which is installed in a housing and can rotate around a horizontal axis, and the circumference of the roller is usually equipped with a beating member 5, such as a beating pin or a tooth pin. During operation, the roller 3 rotates in the direction of the arrow through a drive motor (not shown). Below the underside of the roller 3 is provided with a cleaning grid 4 .

[0023] The upper side of the roller 3 is covered at a distance from the periphery of the roller by a wall which is provided with a horizontal middle area and two side areas which are laterally adjoining the horizontal middle area and are inclined at approximately 45°, and in addition are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com