Fiber low-damage output device for continuous blowing-carding feeding hopper

A technology of output device and blowing carding unit, which is applied in fiber treatment, deburring device, textile and paper making, etc. It can solve the problems of secondary pollution of cotton layer, easy generation of step difference, unstable sliver quality index, etc., and reduce faults , Improve cohesion and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

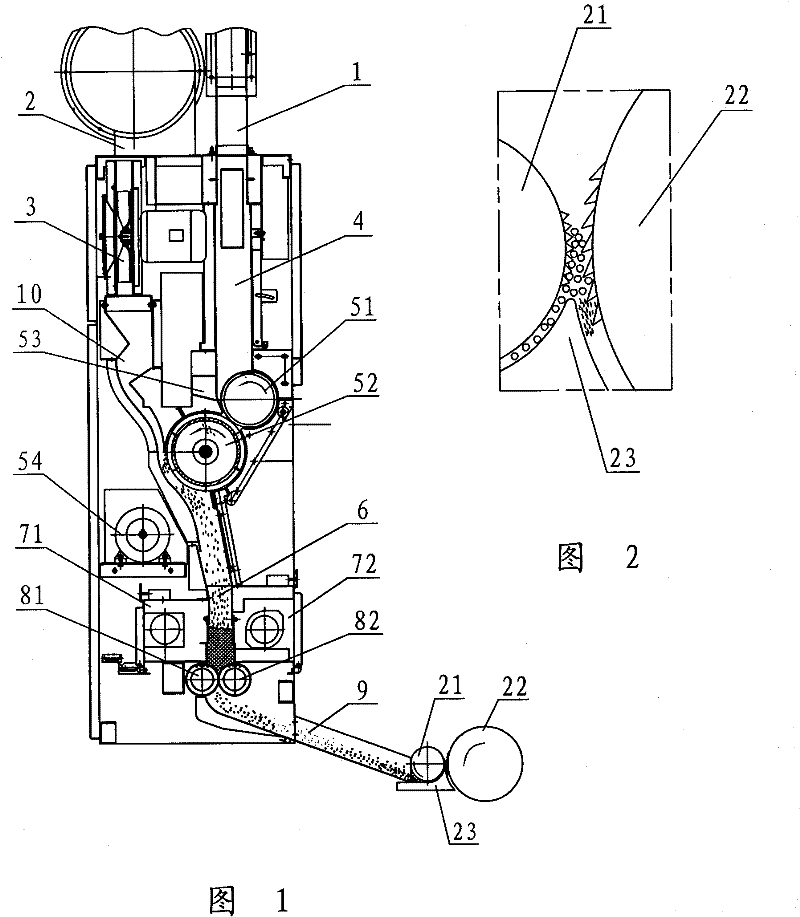

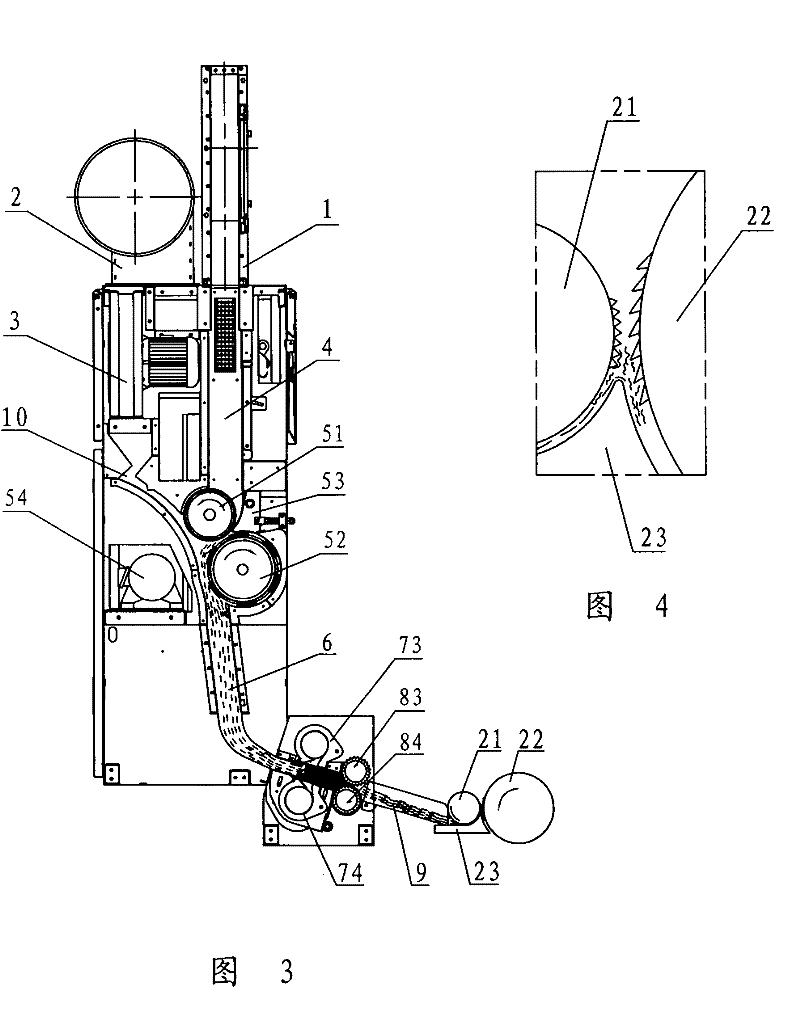

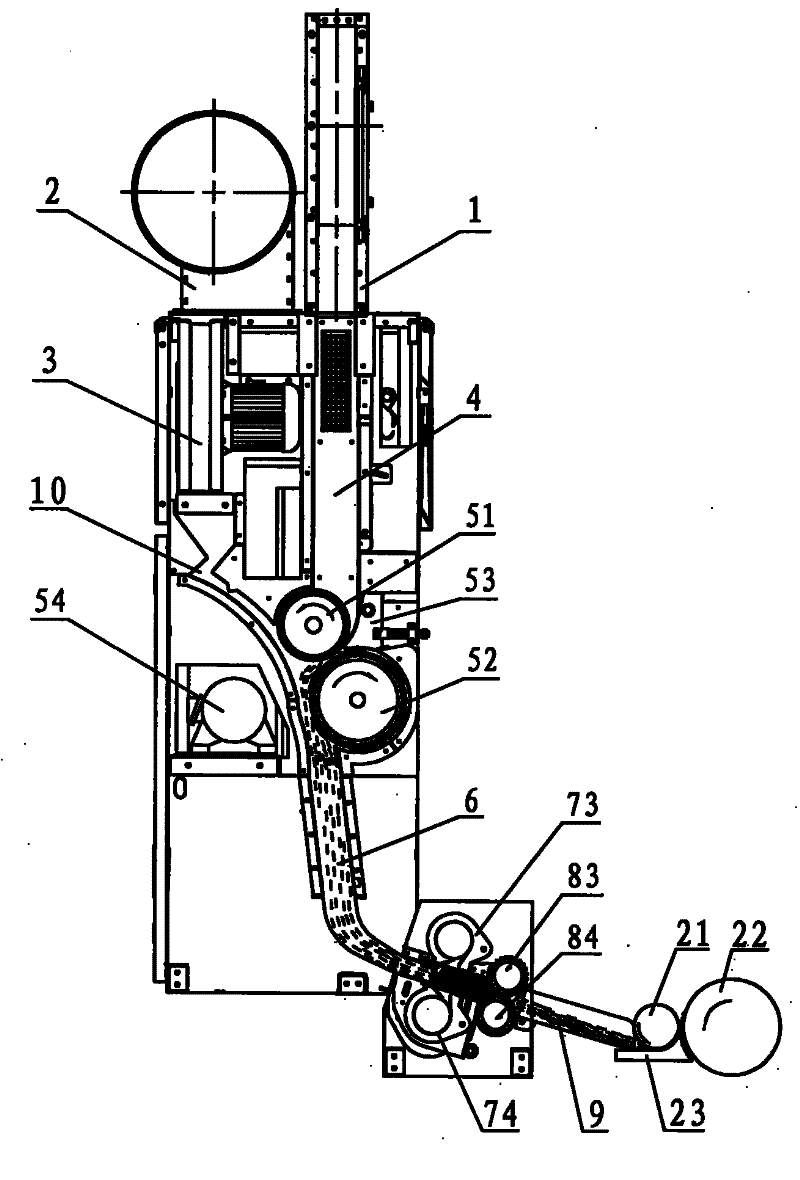

[0018] Attached below Figure 3 ~ Figure 4 The present invention is further described:

[0019] image 3 To be equipped with the blowing-carding fiber low-damage cotton feeding box of the present invention, it includes a cotton head 1, a dust discharge pipe 2, a blower 3, an upper channel for conveying cotton 4, an opening part and a lower channel for conveying cotton 6, and a dust-absorbing part , the output roller part and the cotton dripping plate 9, the cotton distribution head 1 and the dust discharge pipe 2 are all arranged on the top of the cotton box, the cotton distribution head 1 communicates with the upper cotton conveying channel 4, and the opening part is arranged on the cotton conveying upper channel 4, At the junction of the cotton conveying lower channel 6 and the air duct 10, the opening parts include a cotton feeding roller 51, a beating hand 52 and a cotton feeding plate 53, and the cotton feeding plate 53 is arranged on the right side of the engagement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com