Superfine wool fiber spunyarn, and its spinning method

A technology of wool fiber and spun yarn, which is applied in fiber processing, yarn, textile and papermaking, etc., and can solve the problems of further improvement of texture, grade, use and value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

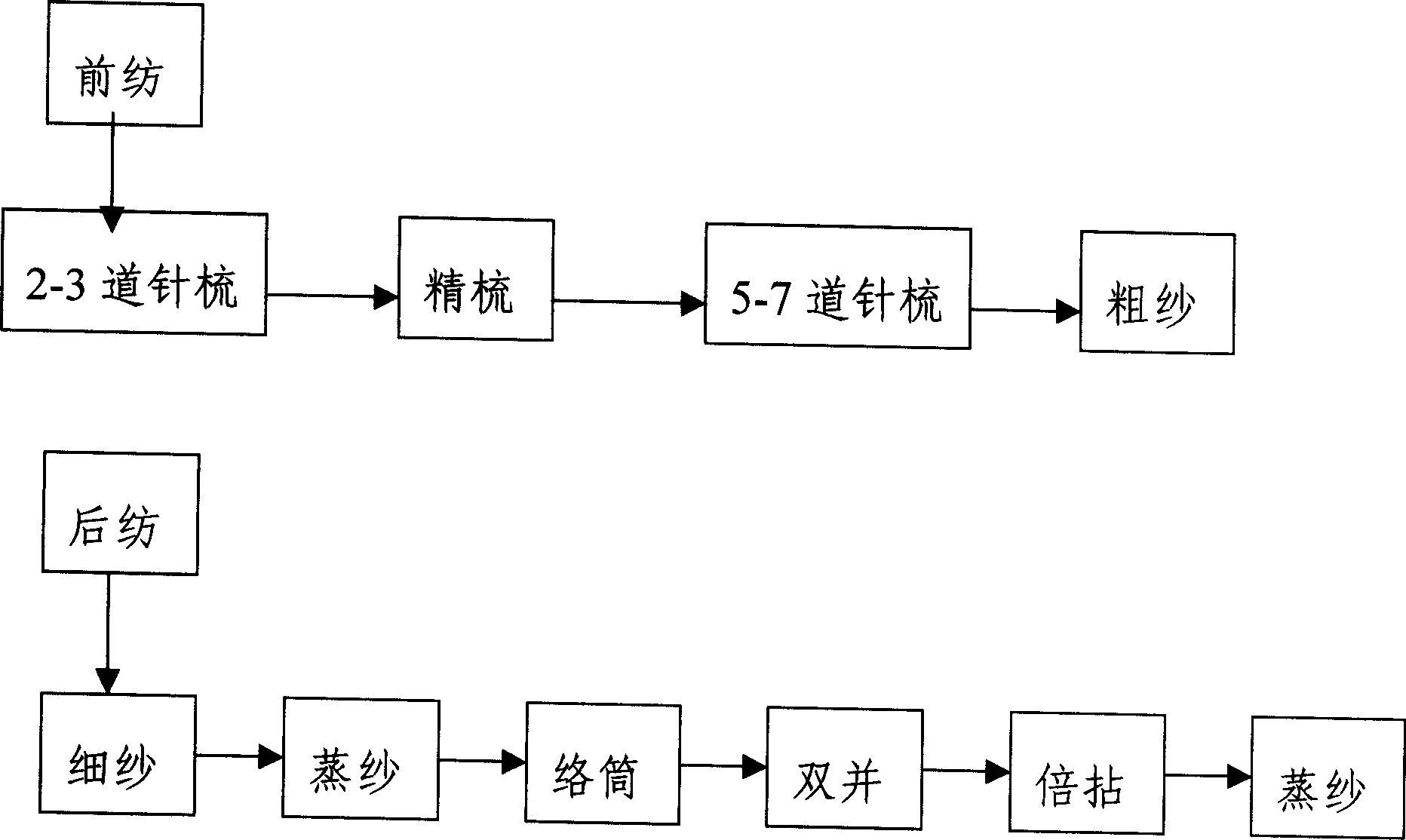

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1 spins the superfine wool fiber spun yarn of the present invention.

[0063] The ultra-fine wool fiber top used for spinning the ultra-fine wool fiber spun yarn in this embodiment is the ultra-fine wool fiber top produced by the applicant in 2005, and the fiber average length of the ultra-fine wool fiber top is 50.0-54.50mm , the discrete fiber length is 47.50-49.0%, the discrete fiber fineness is 17.0-18.0%, the short hair content of <30mm is 20.0-22.8%, the finished wool top is 1.5-7.65 per gram, and the oil content of the finished wool top is 0.80- 1.98% (see the applicant's Chinese patent application with the patent application number "200510029584.6", the title of invention being "a top of superfine wool fiber and its manufacturing method"). The superfine wool fiber top is made of 100% super-grade Merino wool fiber produced in Australia with an average diameter of 11-12 microns.

[0064] 1. Design of count and twist: because the quantity of this batch ...

Embodiment 2

[0083] Spinning the superfine wool fiber spun yarn of the present invention, except that the single yarn count of the superfine wool fiber spun yarn in the present embodiment is 170 public support, the strand count is 170 / 3 public support, and the single yarn twist is determined as 1270Z, The strand twist is determined as 1200S, and others are the same as embodiment 1, spinning the superfine wool fiber spun yarn of the present invention.

[0084] Quality Index

[0085] The single yarn CV value of the spun yarn is 19.81%, the CV value of the strand after steaming is 12.67%, the breaking strength of the single yarn of the spun yarn is 41 (cN / dtex), and the breaking strength of the strand after steaming is 171 (cN / dtex). dtex), the single yarn elongation of the spun yarn is 7.59%, and the strand elongation is 12.1 (%).

Embodiment 3

[0087] Spinning the superfine wool fiber spun yarn of the present invention, except that the single yarn count of the superfine wool fiber spun yarn in the present embodiment is 175 public support, the strand count is 175 / 3 public support, and the single yarn twist is determined as 1265Z, The strand twist is determined as 1220S, and others are the same as embodiment 1, spinning the superfine wool fiber spun yarn of the present invention.

[0088] Quality Index

[0089] The CV value of the single yarn of the spun yarn is 20.11%, the CV value of the strand after steaming is 11.67%, the breaking strength of the strand after the steaming of the spun yarn is 171 (cN / dtex), and the strand elongation is 12.8 (%) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com