Carding equipment of collagenous fibers

A collagen fiber and equipment technology, applied in the field of collagen fiber carding equipment, can solve the problems of inability to apply collagen fiber processing and low efficiency, and achieve the effects of reducing equipment investment, reducing operators, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

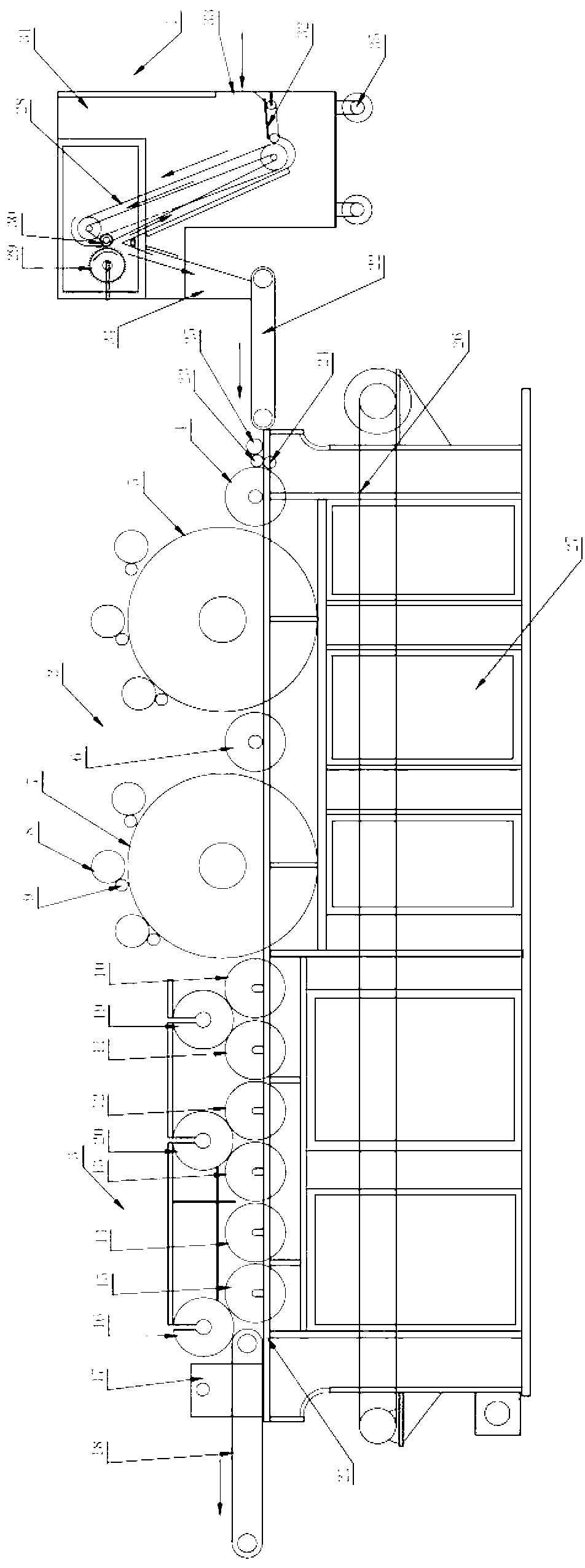

[0020] Such as figure 1 As shown, the present invention is a kind of collagen fiber carding equipment, and this carding equipment is formed by series connection of feeding machine 1, roughing and combing and combing integrated machine, and in the integrated machine, roughing and carding part 2 comprises loosening thorns closely arranged successively Roller 4, the first large cylinder 5, the first transfer roll 6 and the second large cylinder 7, the upper part of the first large cylinder 5 and the second large tin 7 are respectively provided with a working roll 8 and a stripping Roller 9; in the all-in-one machine, the fine-shutting part 3 includes the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com