Combined roller top card

A roller cover, hybrid technology, applied in fiber processing, deburring devices, textiles and papermaking, etc., can solve the problems of long process flow, high labor, low single-machine output, etc., achieve uniform carding tops, reduce fiber damage, The effect of improving the quality of the sliver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

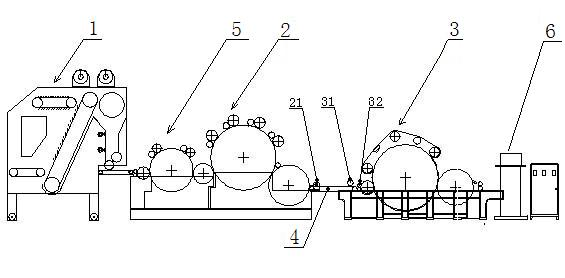

[0024] figure 1 Shown is the structural representation of the present invention.

[0025] The present invention comprises wool feeding hopper 1, opener 5, carding machine 2, carding machine 3 and wool spinning coiler 6, and described wool feeding hopper 1, opener 5, carding machine 2 and carding machine 3 are connected successively Form a joint engine.

[0026] The present invention is a combination machine composed of a cashmere sliver making machine and a carding machine after improvement.

[0027] The cashmere sliver machine is composed of a wool feeding hopper 1, an opener 5 and a carding machine 2.

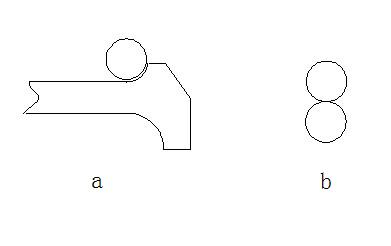

[0028] The present invention removes the coiler 6 of the carding machine 2, and its output part changes the chopping knife stripping device 21 into.

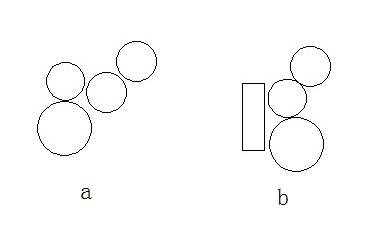

[0029] The carding machine 3 includes a coiler, and the present invention replaces the coiler of the carding ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com