Manufacturing methods and devices of cotton fiber net and multilayer non-woven material

A non-woven material, multi-layer composite technology, applied in non-woven fabrics, fiber processing, textiles and papermaking, etc., can solve problems such as excessive entanglement, uneven cotton fiber web, and uneven non-woven materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

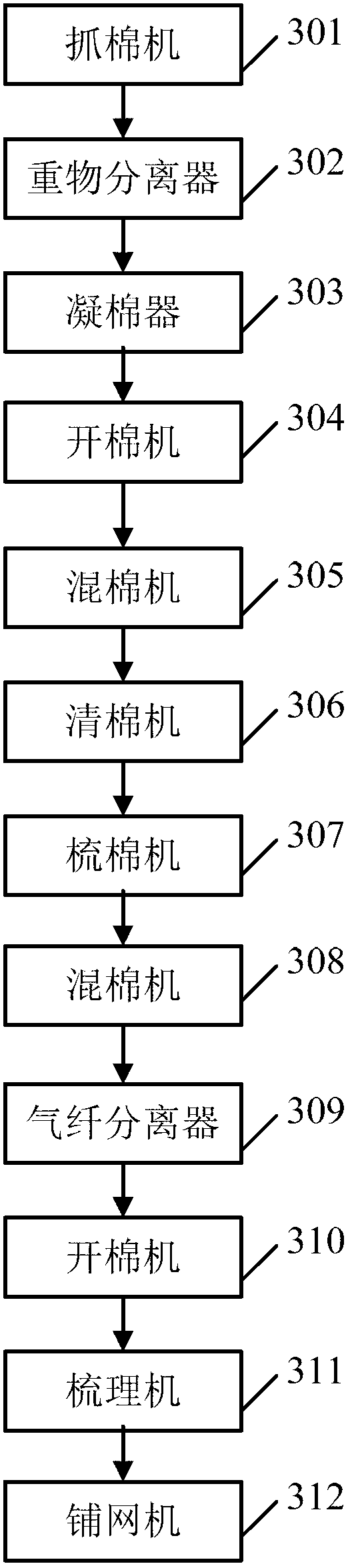

[0131] Please refer to image 3 , the present embodiment provides a kind of manufacturing equipment of cotton fiber web, comprises cotton picking machine 301, weight separator 302, cotton condenser 303, cotton opener 304, cotton mixing machine 305, cleaning machine 306, carding machine 307, cotton blending machine 308, air fiber separator 309, cotton opener 310, carding machine 311, net laying machine 312.

[0132] The cotton catching machine 301 is used to grab the pure cotton raw materials that meet the specifications and send them to the lower-level equipment for processing. Medium and long fibers under 76mm. It should be understood that the pure cotton raw materials referred to in the embodiments of the present application refer to raw materials in which most of the raw materials are cotton.

[0133] The heavy object separator 302 is arranged downstream of the plucking machine 301 and is used for separating and removing the heavy objects mixed in the pure cotton raw mate...

Embodiment 2

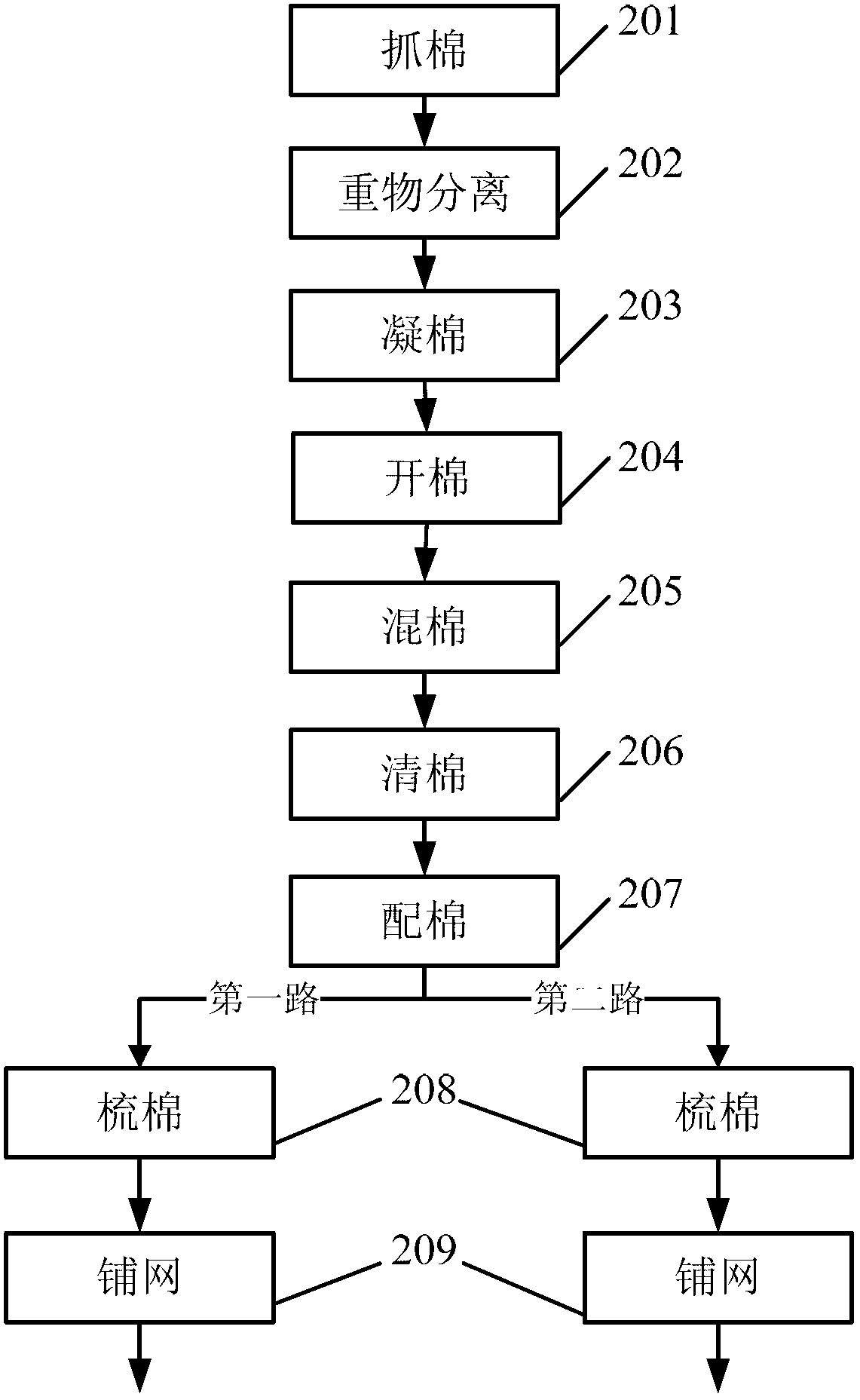

[0146] Please refer to Figure 4 , present embodiment provides a kind of manufacturing method of cotton fiber web, comprising:

[0147] Step 401: Grab pure cotton raw materials that meet the specifications and send them to lower-level equipment for processing. In this embodiment, a reciprocating cotton grabbing machine is used to grab pure cotton raw materials, which is suitable for grabbing various grades of raw cotton, cotton-type chemical fibers, and cotton fibers below 76 mm. In other embodiments, other plucking machines can also be used for medium and long fibers.

[0148] Step 402: Separating and removing the heavy objects mixed in the pure cotton raw material. In this embodiment, the heavy object impurities with large mass are separated and removed from the pure cotton fibers by using the suction of the fan airflow through the heavy object separator. In a specific example, before step 402 and after step 401, an iron absorption step is also included, which is used to de...

Embodiment 3

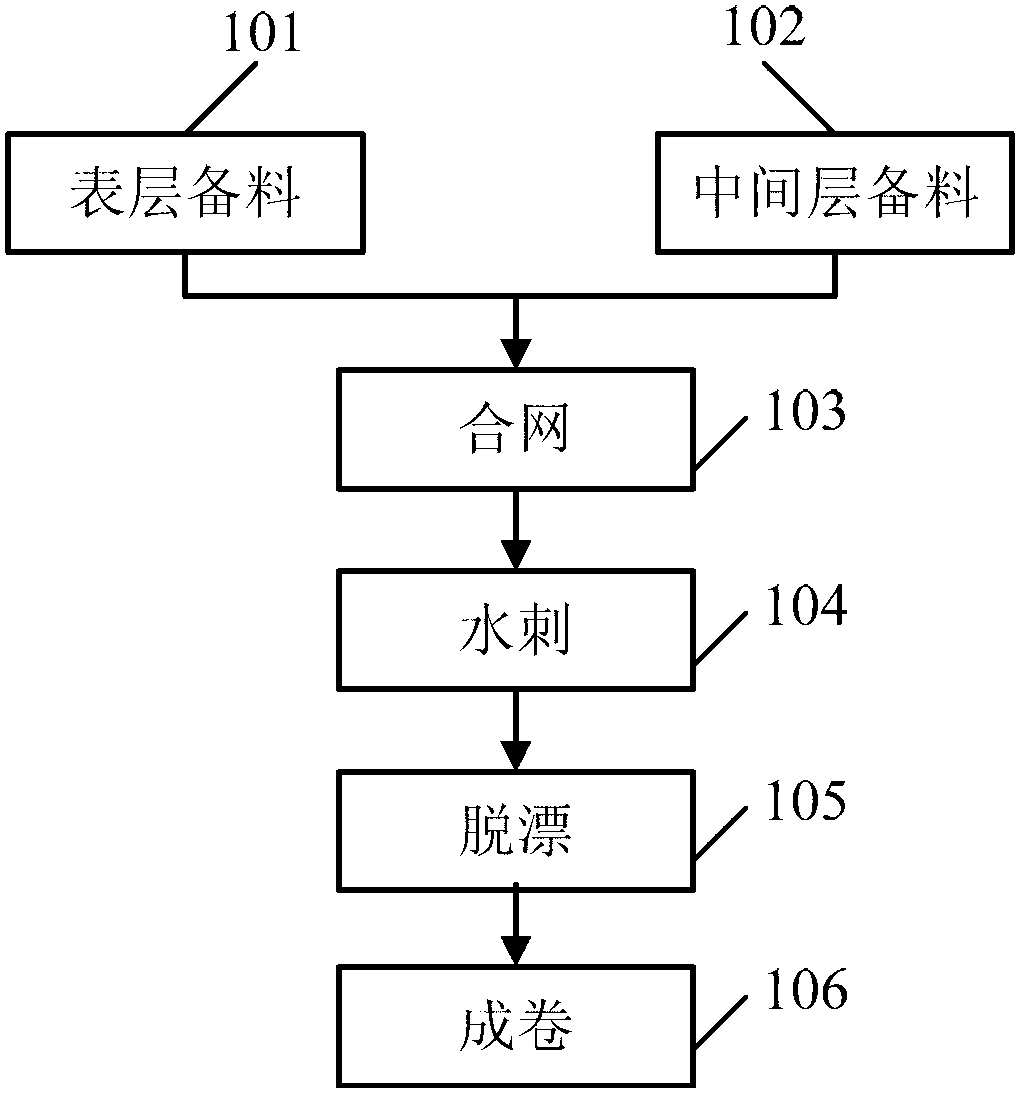

[0161] This embodiment provides a kind of manufacturing equipment of multilayer composite nonwoven material, including the first surface layer material and the second surface layer material used to manufacture multilayer composite nonwoven material, and output the laminated first surface layer material and second surface layer material A surface layer manufacturing device for the surface layer material; an intermediate layer material for manufacturing a multilayer composite nonwoven material, and an intermediate layer manufacturing device for outputting the intermediate layer material between the first surface layer material and the second surface layer material; and for simultaneously The first surface layer material, the second surface layer material and the middle layer material that have been transported are combined and then spunlace to form a multi-layer composite nonwoven material finished product.

[0162] Please refer to Figure 5 , the surface manufacturing device incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com