Carding machine equipment for textile fibers

A technology for textile fibers and carding machines, used in fiber processing, textile and papermaking, deburring devices, etc., can solve problems such as low work efficiency, high fiber damage rate, and unstable quality, and achieve convenient operation, accurate temperature control, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

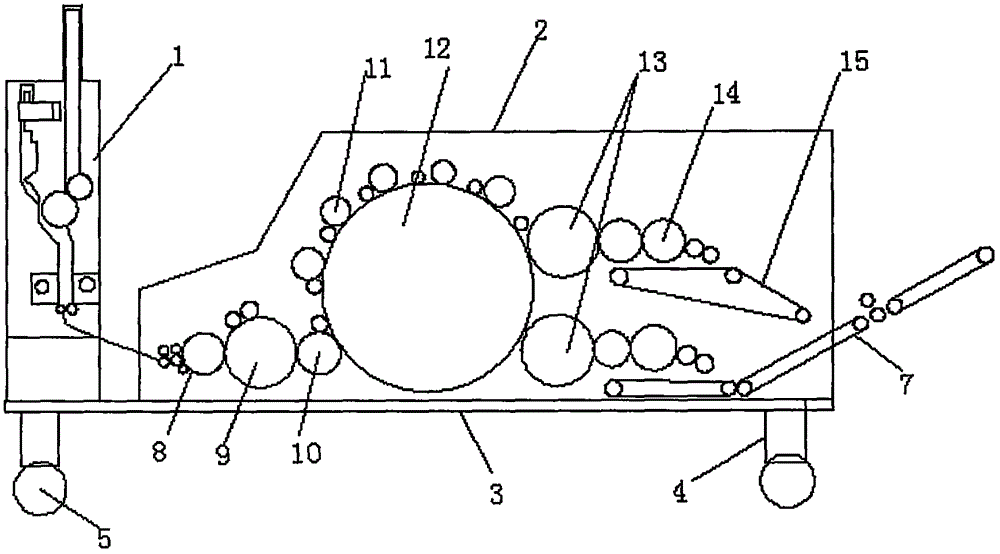

[0018] Such as figure 1 As shown, the carding machine equipment of a kind of textile fiber of the present invention comprises feeding cabinet 1, casing 2, machine base 3, support foot 4, pre-carding mechanism, main carding mechanism, double doffer stripping and combing roller 13, conveying curtain mechanism 15 and a discharge conveyor belt 7, the base 3 is provided with a feeding case 1 and a casing 2, a support foot 4 is provided below the base 3, and a feeding conveyor belt mechanism is provided above the feeding case 1 , the inside of the feeding cabinet 1 is provided with a traction mechanism, and the inside of the casing 2 is sequentially pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com