Tea-leaf automatically de-enzyming straightening out machine and de-enzyming straightening out method thereof

A technology for removing green strips and strips, which is applied in the direction of tea processing before extraction, etc., can solve the problems of high technical requirements of production workers, high labor intensity, low degree of automation, etc., and achieves high degree of automation, low equipment investment, and the The effect of low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

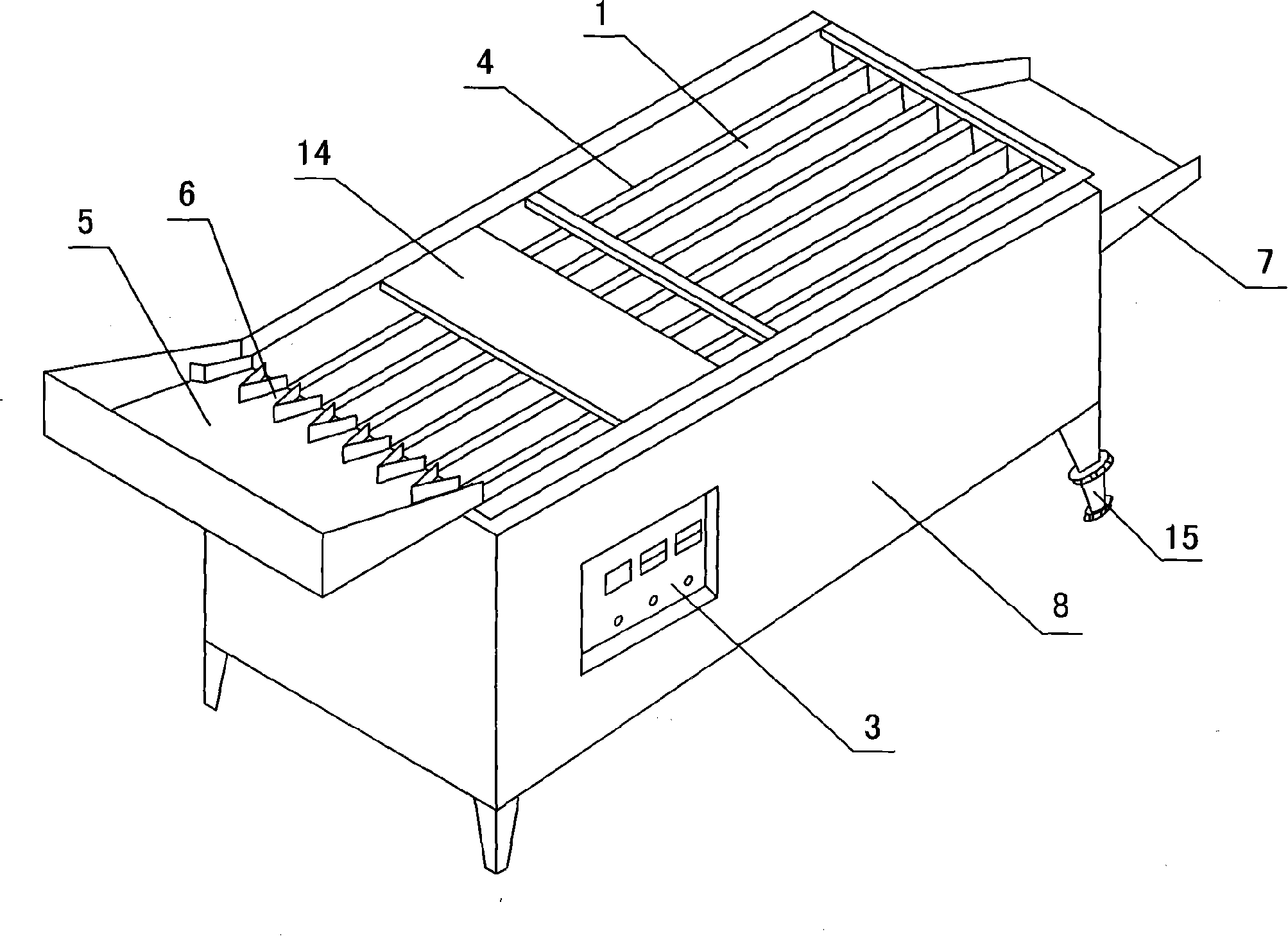

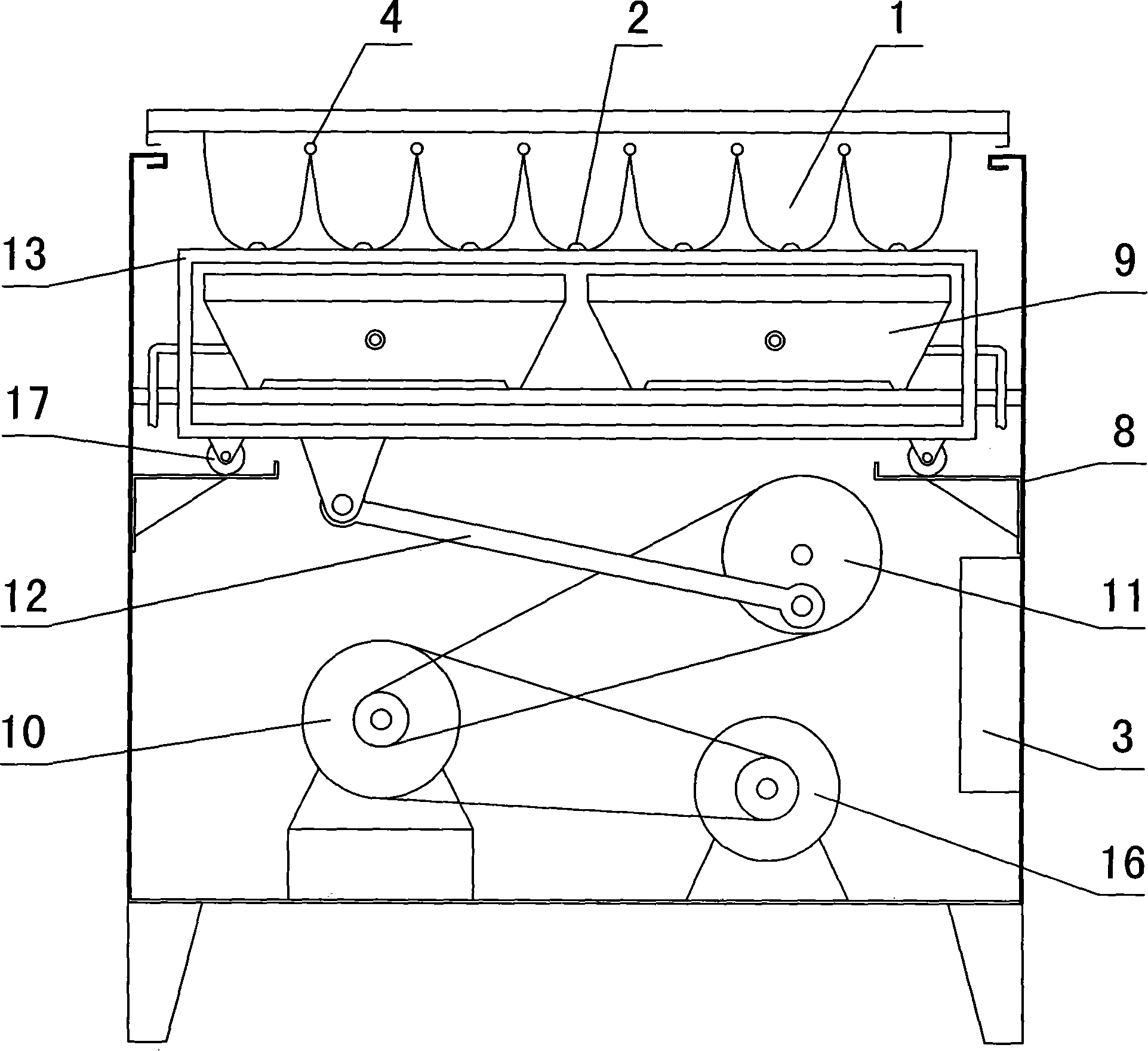

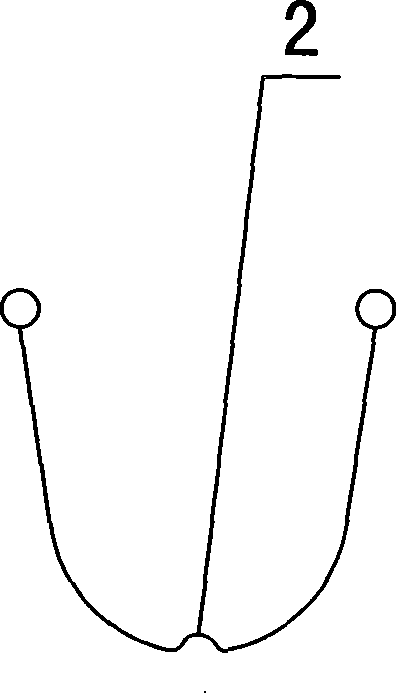

[0024] in such as figure 1 figure 2 In the shown embodiment 1, the automatic greening and stripping machine for tea leaves is composed of a frame body 8, a reciprocating swing multi-slot pot 1 arranged on the frame body 8, and a heating device arranged under the multi-slot pot 1, etc., the multi-slot pot The cross section of 1 is a U-shaped structure, and a raised arc-shaped rib 2 is provided at the bottom (see image 3 ), the height of rib 2 protrusions is 5 millimeters, and it is an integrated structure of equal wall thickness with the pot body of multi-slot pot 1. The groove number of multi-groove pot 1 is 7, and groove width is 100 millimeters, and the joint of groove and groove is provided with round bar 4. The left side of the multi-groove pot 1 is the finishing area, and the right side is the stripping area. The number of grooves in the stripping area is consistent with the stripping area, and the finishing and stripping of tea leaves are carried out continuously in ...

Embodiment 2

[0029] in such as Figure 6 In the shown embodiment 2, its U-shaped groove is provided with 10 degree of inclination angle toward the same direction when the groove of multi-slot pot is connected with the groove, and all the other are identical with embodiment 1. If the ribs at the bottom of the multi-slot pot 1 are changed into two (see Figure 4 ) or three (see Figure 5 ), or the number of grooves in the strip zone of the multi-groove pot is set to twice that of the finishing zone, a new embodiment can be formed.

[0030] When using the tea automatic degreening and stripping machine, first set the optimal temperature required for degreening and stripping according to the size of the fresh tea leaves and the degree of dryness and humidity (preferably 280 degrees to 320 degrees for the tea stamping area, and 110 degrees for the tea stripping area. temperature to 140 degrees), turn on the heating system to preheat the tea machine, when the multi-slot pot reaches the set temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com