Pearl fiber shirt fabric and preparation method thereof

A pearl fiber and fabric technology, applied in the field of shirt fabrics, can solve the problems of few functional new fiber manufacturers, reduce consumers' willingness to consume, and poor spinnability of new fibers, and achieve the effect of plump hand, elegant luster, and bright luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

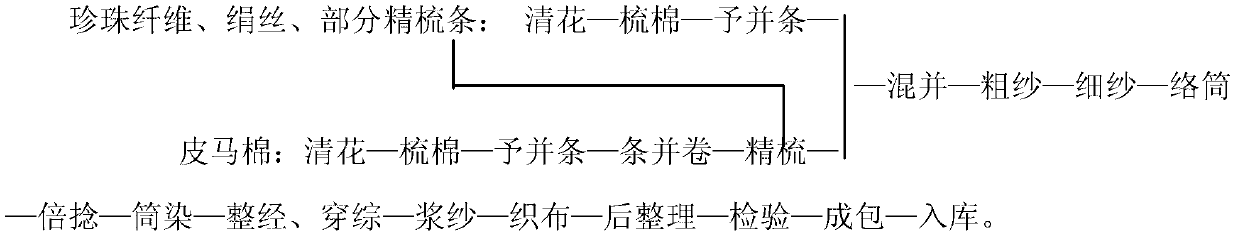

[0030] 1. Production process

[0031] Warp and weft: pearl 30 / spun silk 20 / long staple cotton 50CF120 S / 2

[0032]

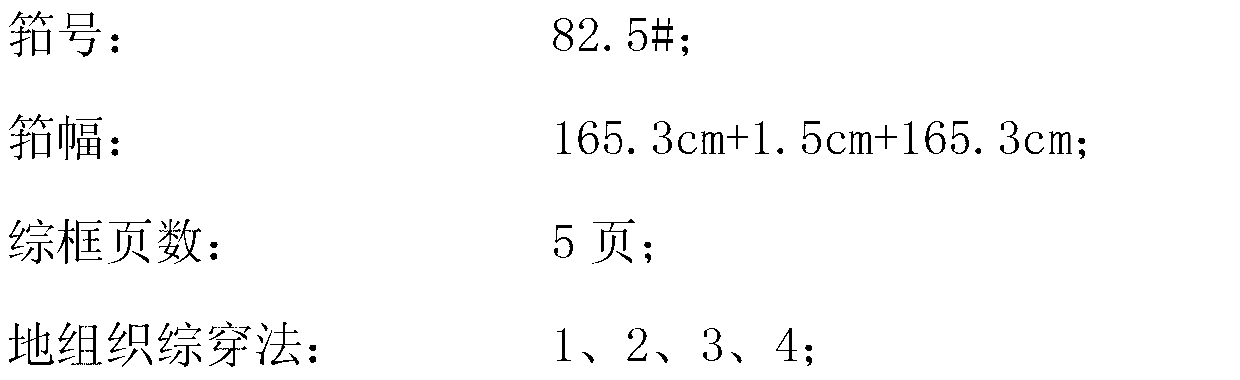

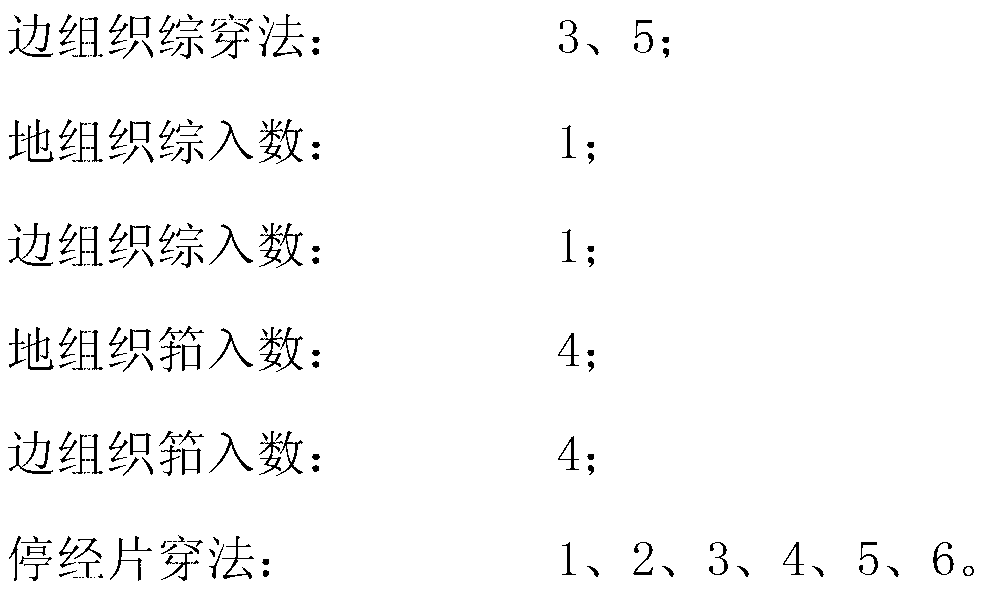

[0033] Second, the production process parameters and technical key

[0034] 1. Spinning:

[0035] Warp and weft: pearl 30 / silk 20 / long-staple cotton 50CF120S / 2

[0036] Pima cotton: (clear flowers)

[0037] ①Dry weight of raw sliver 19.6g / 5m, sliver delivery speed 70m / min, cylinder-cover gauge 8*7*7*7*8″;

[0038] ②The pre-quantitative dry weight is 20.3g / 5m, and the combined number is 6;

[0039] ③ The quantitative dry weight of strips and rolls is 65g / m, and the combined number is 24;

[0040] ④ Combing machine E62, quantitative dry weight 20.5g / 5m, noil rate 15%.

[0041] Pearl fiber, spun silk, some combed long-staple cotton (clean):

[0042] ①Comprehensive beater speed 750r / min, comprehensive beater-dust bar: in-out 8*18mm, cotton lap weight 336g / m;

[0043] ②Dry weight of raw sliver 24.5g / 5m, sliver delivery speed 60m / min, cylinder-to-cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com