Face fabric containing ceiba fiber and producing technique thereof

A kapok fiber and fabric technology, applied in the direction of fabrics, textiles, textiles and paper making, etc., can solve the problems of hard board, poor thermal insulation performance, and heavy fiber quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

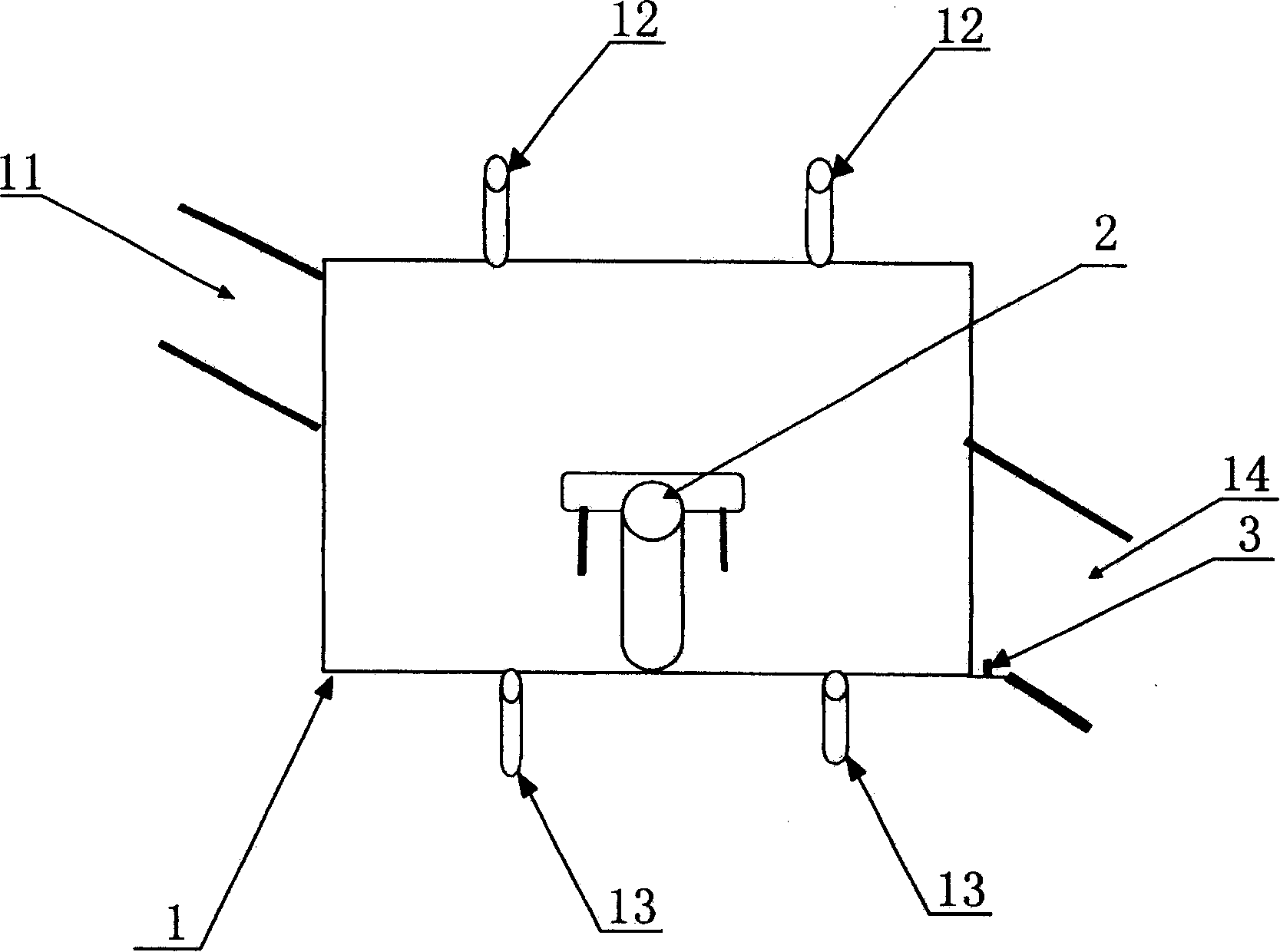

Image

Examples

Embodiment 1

[0039] A kapok fabric containing kapok fibers is 100% composed of kapok fibers.

[0040] The weaving and knitting method of a fabric containing kapok fibers comprises the following process steps:

[0041] Raw material pretreatment - cotton cleaning - high temperature and high humidity synchronous carding into slivers - sliver merging - spinning - bleaching - weaving or knitting weaving - dyeing and finishing - making woven and knitted kapok fabrics.

[0042] Spun into 10s yarn and woven into kapok fabric. Weaving includes: air spinning, ring spinning.

[0043] Further, the process parameters are as follows:

[0044] (1) Cotton cleaning, high temperature and high humidity synchronous carding into slivers, sliver merging, and spinning process parameters are controlled as follows:

[0045] Cotton cleaning: lap weight 200 g / m, lap roller speed 13 rpm;

[0046] High temperature and high humidity synchronous combing into slivers: the temperature of high temperature and high humi...

Embodiment 2

[0061] A kapok fabric containing kapok fibers is composed of kapok fibers and cotton; the content is 50% of kapok fibers and 50% of cotton.

[0062] The above-mentioned fibers are mixed and spun into 16s yarns to be woven into fabrics containing kapok fibers.

[0063] The above-mentioned weaving and knitting method for fabrics containing kapok fibers includes the following process steps: raw material pretreatment-cleaning-high temperature and high humidity synchronous carding into slivers-sliver merging-spinning-bleaching-weaving or knitting weaving-dyeing Whole-made into woven and knitted kapok fabrics.

[0064] Further, the process parameters are as follows:

[0065] (1) Cotton cleaning, high temperature and high humidity synchronous carding into slivers, sliver merging, and spinning process parameters are controlled as follows:

[0066] Cotton cleaning: lap weight 250 g / m, lap roller speed 16 rpm;

[0067] High temperature and high humidity synchronous combing into slive...

Embodiment 3

[0081] A kapok fabric containing kapok fiber, composed of kapok fiber and camel hair; the content is 90% kapok fiber and 10% camel hair.

[0082] The above-mentioned fibers are mixed and spun into 32s yarns to be woven into fabrics containing kapok fibers.

[0083] The above-mentioned weaving and knitting method for fabrics containing kapok fibers includes the following process steps: raw material pretreatment-cleaning-high temperature and high humidity synchronous carding into slivers-sliver merging-spinning-bleaching-weaving or knitting weaving-dyeing Whole-made into woven and knitted kapok fabrics.

[0084] Further, the process parameters are as follows:

[0085] (1) Cotton cleaning, high temperature and high humidity synchronous carding into slivers, sliver merging, and spinning process parameters are controlled as follows:

[0086] Cotton cleaning: lap weight 200 g / m, lap roller speed 13 rpm;

[0087] High temperature and high humidity synchronous combing into slivers:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com