Suspension noise-reduction motor

A suspension-type, noise-reducing technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of reduced air volume, small air intake area of the motor air inlet, and affecting the working efficiency of the vacuum cleaner, achieving noise reduction and quietness Working environment, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

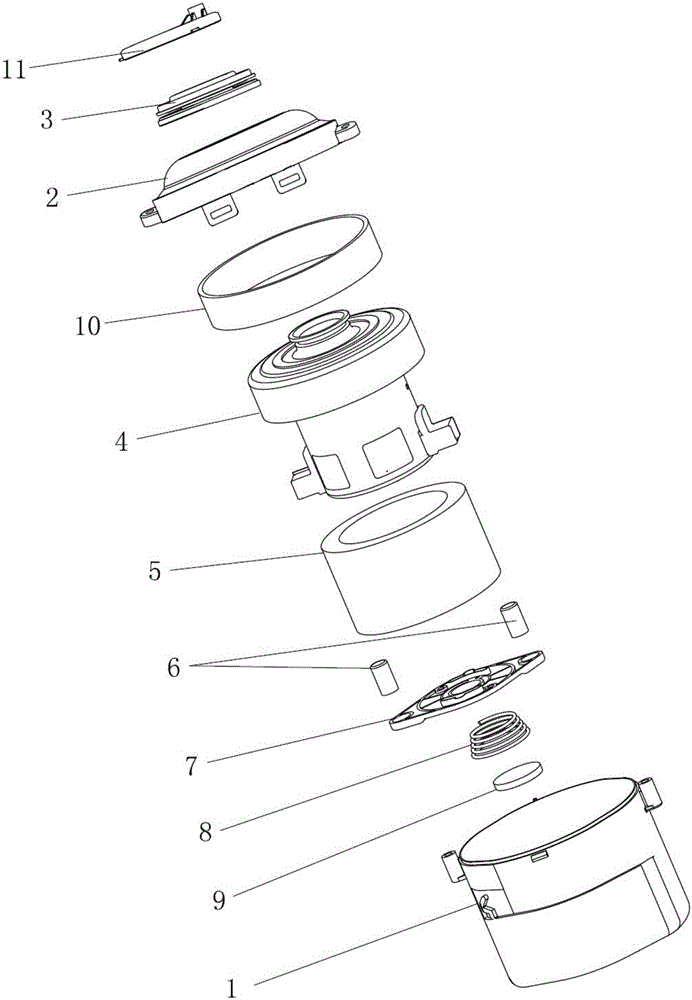

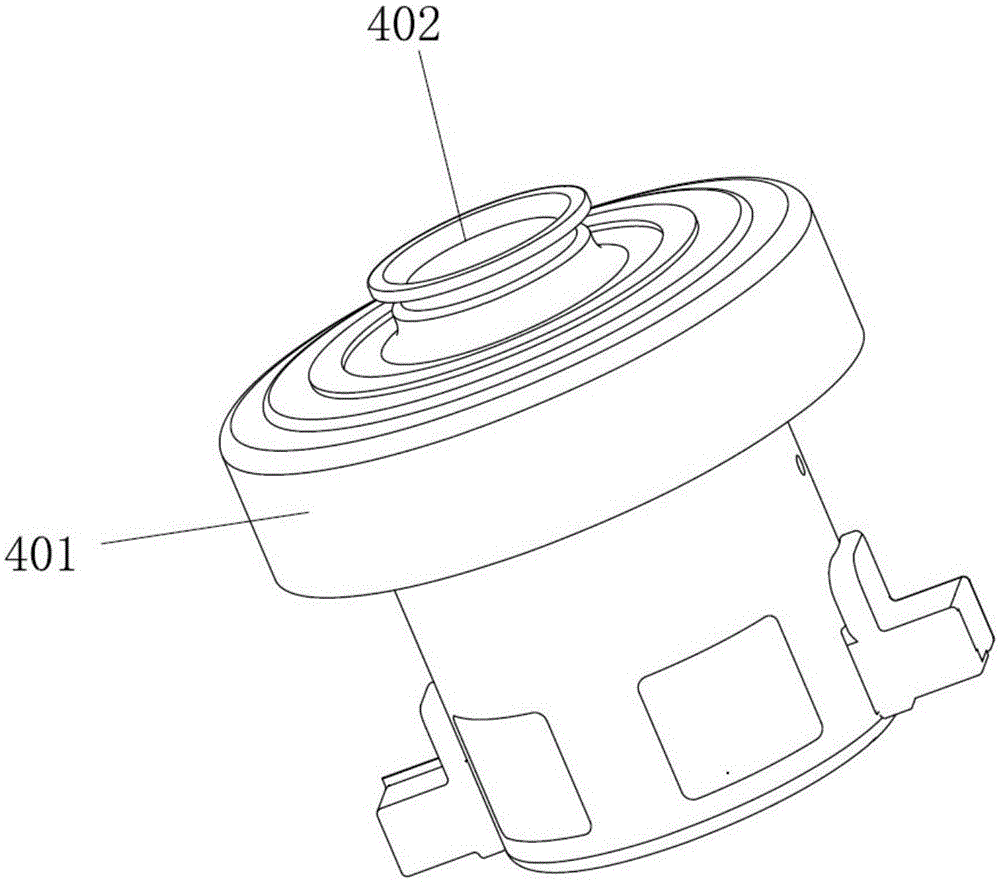

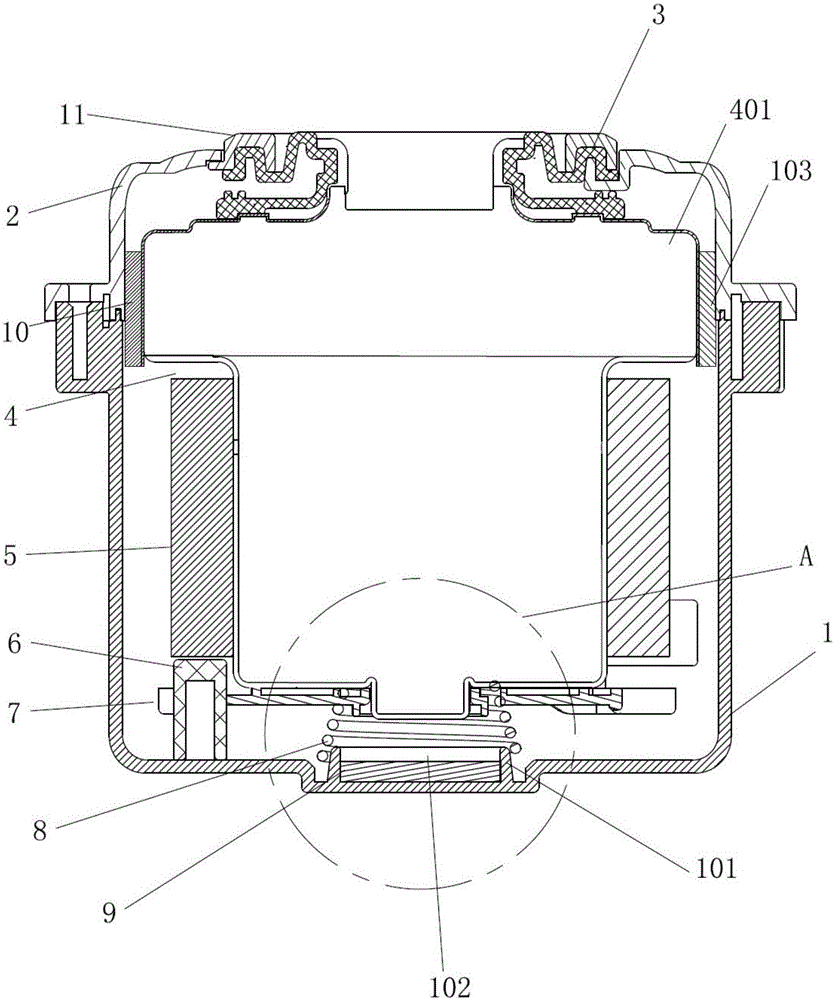

[0072] Please refer to Figure 1 to Figure 3 , figure 1 It is the explosion diagram of the suspension type noise reduction motor of this embodiment, figure 2 It is a structural schematic diagram of the motor main body of the suspension type noise reduction motor in this embodiment, image 3 It is a schematic diagram of the structure of this embodiment. Suspension type noise reduction motor, including motor body 4, and motor cover 1 at least partially containing motor body 4, sealing ring 3 sleeved on motor body air inlet 402, and buffer installed between motor body 4 and motor cover 1 Components, the sealing ring 3 and several buffer components allow the motor body 4 to move in three-dimensional space.

[0073] In this embodiment, the air inlet 402 of the main body of the motor is upward.

[0074] In specific production, in order to facilitate production and assembly, motor cover 1 can be provided with motor cover 2, like this, motor cover 2 contains the head and shoulder...

Embodiment 2

[0086] The specific implementation of this embodiment is as follows. The technical features introduced below are the differences from the first embodiment. The sealing ring, side cushion, bottom cushion and shockproof sleeve are all the same as the first embodiment.

[0087] Please refer to Figure 8 and Figure 9 , Figure 8 and Figure 9 They are the exploded schematic diagram and the assembled structure schematic diagram of this embodiment respectively. In this embodiment, the air inlet 401 of the motor body is downward, and an elastic mechanism 8 is provided between the bottom of the motor body and the motor cover 1 , and the elastic mechanism 8 exerts a pulling force on the motor body 4 .

[0088] Further, the bottom of the motor cover 1 is provided with an opening 104, and the opening 104 is provided with a limiting mechanism for limiting the motor body 4 downward.

[0089] Please refer to Figure 10 , Figure 10 yes Figure 9 In the enlarged view, the structure o...

Embodiment 3

[0093] Please refer to Figure 13 to Figure 15 , Figure 13 It is a schematic diagram of the decomposition of the suspension noise reduction motor of this embodiment, Figure 14 It is a structural schematic diagram of the suspension type noise reduction motor of this embodiment, Figure 15 It is the front view of the suspension type noise reduction motor of this embodiment. Suspension type noise reduction motor, including motor body 16, and motor cover 15 at least partially containing motor body 16, sealing ring 18 sleeved on the air inlet of motor body 16, and buffer installed between motor body 16 and motor cover 15 Components, the sealing ring 18 and several buffer components allow the motor body to move in three-dimensional space.

[0094] In this embodiment, the motor cover 15 includes a left motor cover 151 and a right motor cover 152, and the left motor cover 151 and the right motor cover 152 are fastened to completely contain the motor body 16; the sealing ring 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com