Cylindrical steel shell battery and manufacturing method thereof

A profiled steel and battery technology, applied in the field of new energy vehicle energy storage power batteries, can solve the problems of low manufacturing environment dew point, difficult equipment realization, complex manufacturing process, etc., to reduce inactive material space, improve volume specific energy and weight High specific energy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

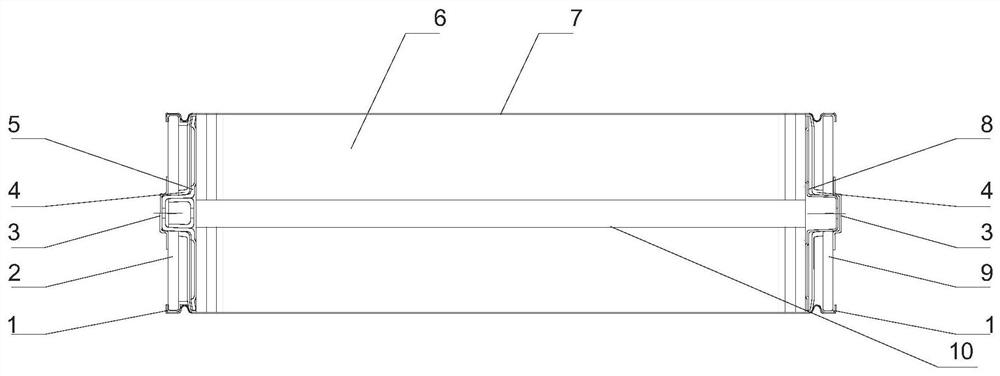

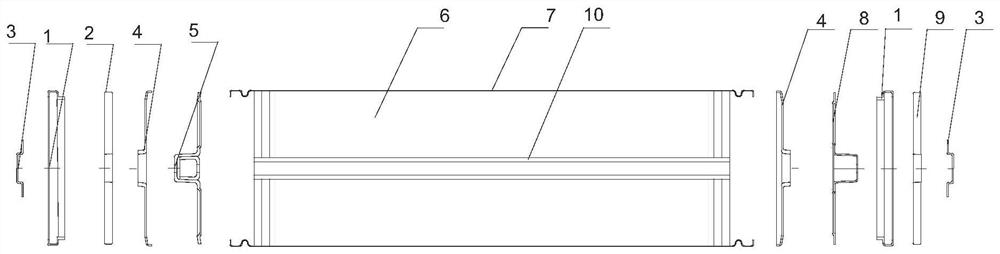

[0070] Example 1 ( Figure 1 to Figure 12 )

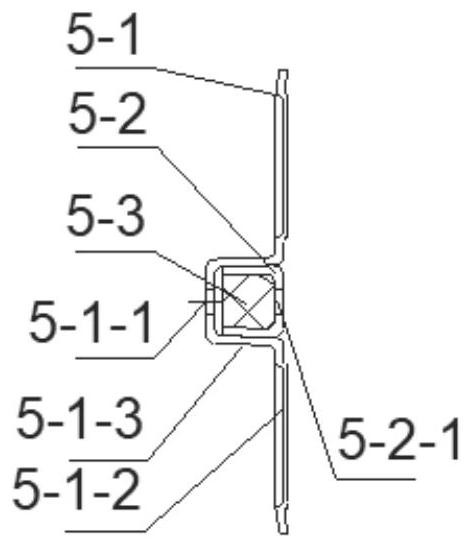

[0071] Such as Figure 1 to Figure 12 As shown, the cylindrical battery of the present invention includes a sealing ring 1, a positive electrode cover plate (aluminum) 2, a sealing sheet (aluminum) 3, a collector plate protective cover 4, a positive electrode collector plate assembly (aluminum) 5, and a full pole ear coil Core 6, Steel Shell 7; Negative Electrode Current Collector Assembly (Copper) 8, Negative Electrode Cover Plate (Copper / Copper-Aluminum Composite) 9, Center Tube 10.

[0072] The structure of the positive / negative plate in the positive and negative collector plate assembly is as follows: image 3 , Figure 4 Shown is a U-shaped configuration.

Embodiment 2

[0073] Example 2 ( Figure 13 , Figure 14 )

[0074] Such as Figure 13 , Figure 14 As shown, the structure of the positive / negative plate in the positive and negative collector plate assembly is different, Figure 13 , Figure 14 For flat type. image 3 , Figure 4 It is a U-shaped structure. The above are only two forms of the positive / negative pole supporting plate, the purpose is to fix and compress the internal sealing member, and its structural shape is not limited to the above two forms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com