Method for surface modification of medical beta titanium alloy by laser remelting technology

A β-titanium alloy, laser remelting technology, applied in the coating process and coating of metal materials, can solve the problems of poor conductivity and weldability, unsatisfactory effect, poor wear resistance, etc., to achieve enhanced Fine-grain strengthening effect, increased hardness, and easy-to-thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment relates to a method of modifying the surface of medical β-titanium alloy using laser remelting technology. The specific steps are as follows:

[0041] (a), material surface treatment: after rolling and annealing, the surface of β titanium alloy with a thickness of 0.8mm is polished to remove scale, straightened, and the surface is smooth and flat, and then cleaned with acetone to keep the surface of the sample clean; The annealing time of the rolling annealing is 5min.

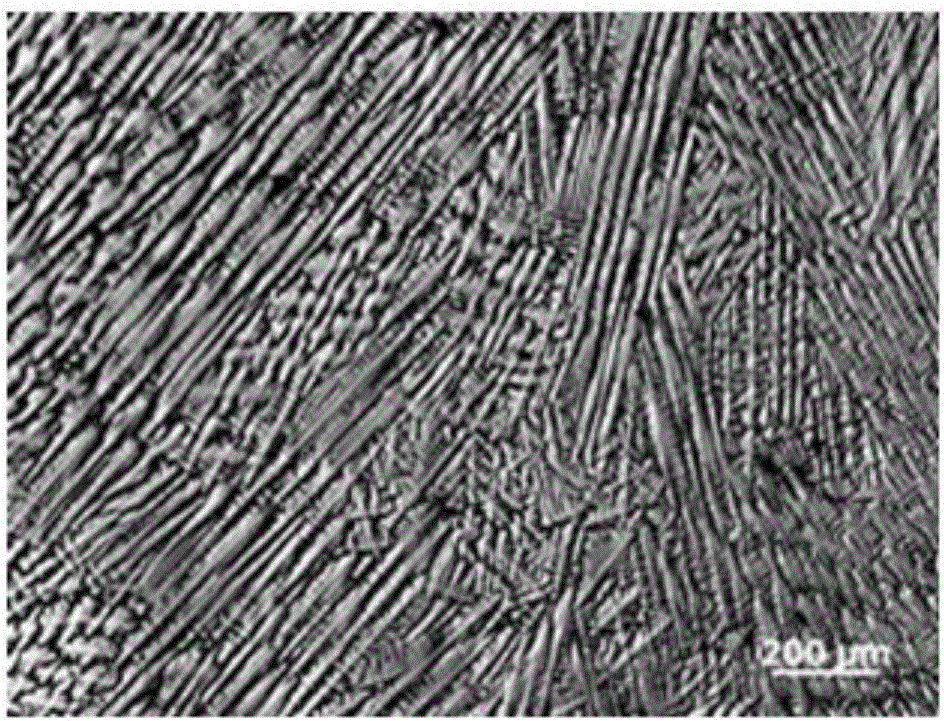

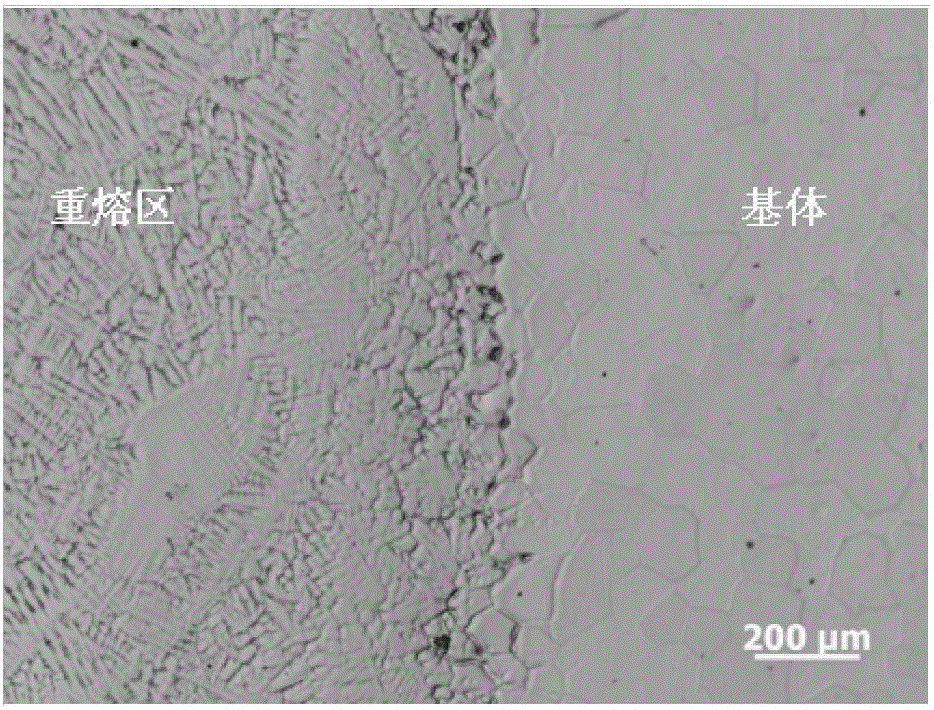

[0042](b), install and process the sample: the laser is a 3.5 kilowatt ROFIN DL 035Q semiconductor laser, and the wavelength of the output laser is 808nm-940nm. When performing laser remelting, the spot at the laser focus is rectangular, and its size is 2.0mm×3.3mm. Fix the β-titanium alloy on the workbench of the semiconductor laser equipment with a fixture, and set the processing parameters: the laser remelting power is 450W, the scanning speed is 2mm / s, the distance between the laser...

Embodiment 2

[0047] Using laser remelting treatment to modify the surface of medical β titanium alloy, the specific steps refer to Example 1, the differences are as follows:

[0048] The processing parameters of laser remelting of medical β-titanium alloy with a thickness of 1.0mm after rolling and annealing: the laser remelting power is 500W, the scanning speed is 5mm / s, and the gas flow rate of argon protection is 30L / min.

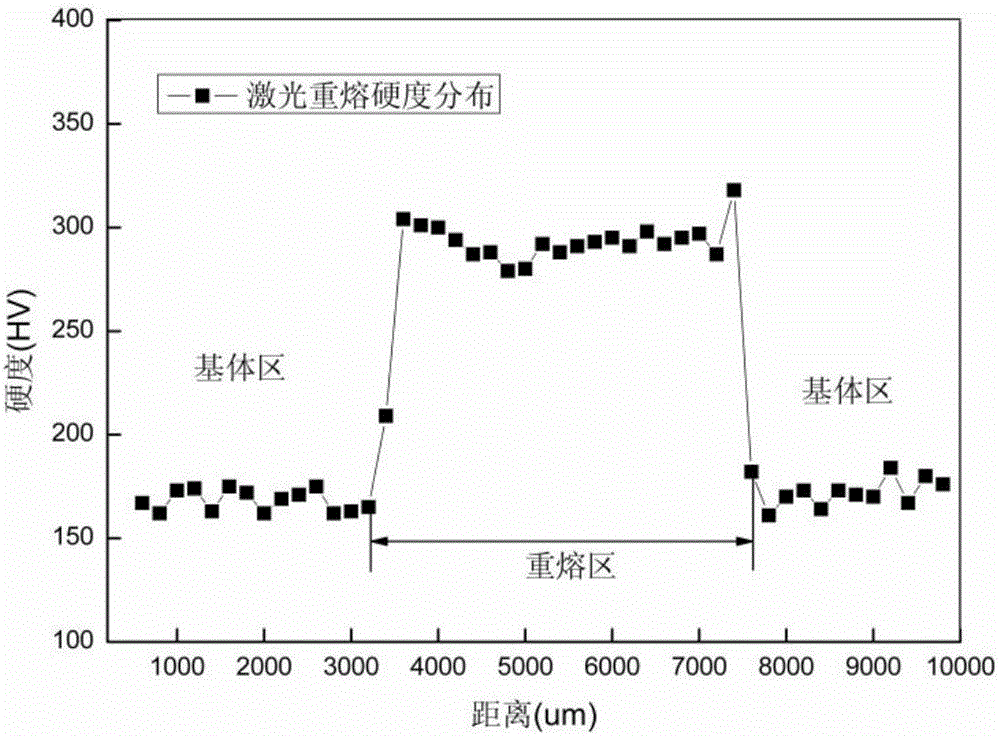

[0049] After the remelting surface modification treatment, the hardness of the remelting area is about 150HV higher than that of the base metal.

Embodiment 3

[0051] Using laser remelting treatment to modify the surface of medical β titanium alloy, the specific steps refer to Example 1, the differences are as follows:

[0052] The process parameters of laser remelting modification of medical β-titanium alloy with a thickness of 0.6mm after rolling and annealing were designed: the laser remelting power was 350W, the scanning speed was 1mm / s, and the gas flow rate of argon protection was 20L / min.

[0053] After the remelting surface modification treatment, the hardness of the remelting area is about 100HV higher than that of the base metal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com