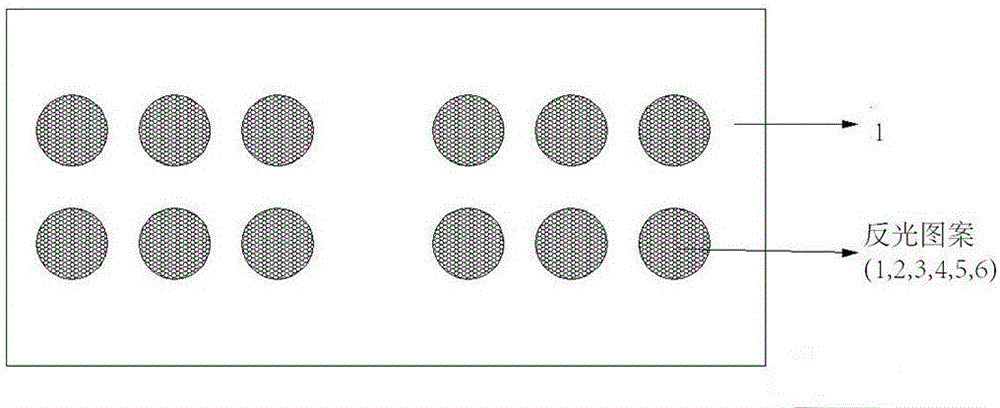

High-efficiency wide air-permeable fancy-type reflecting material and preparation method therefor

A reflective material and high-efficiency technology, applied in optics, optical components, instruments, etc., can solve the problems of single style, lack of breathability, sweat absorption, single color, etc., and achieve the effect of clear pattern, no exhaust gas emission, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

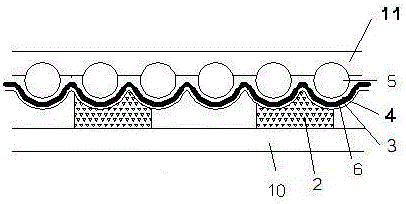

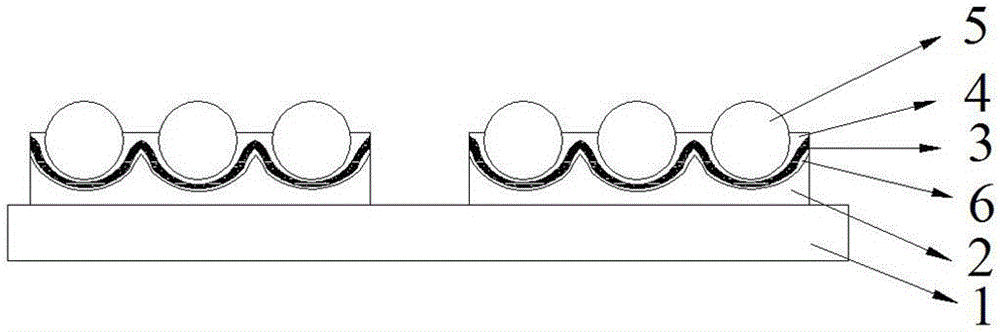

[0044] 1) Implantation of glass beads: put glass beads (5) with a refractive index of 1.91 and a particle size of 20 μm on a PE / PET composite film (11), and then place them in a hot roller at a temperature of 140°C. With the melting of the PE film, the glass beads settle on the PE film, and when the PE film is cooled, the glass beads are fixed on the PE / PET composite film to realize the implantation of the glass beads;

[0045] 2) Coating the focusing coating concentric with the glass beads on the surface of the glass beads (5) in step 1), then drying the solvent through an oven to form a focusing layer (4), the thickness of the focusing layer (4) being 0.1um ;

[0046] The focusing paint is prepared by mixing 60 parts of solvent-based acrylic resin, 2 parts of commercially available Bayer N-75, 2 parts of silane coupling agent KH-550, and 150 parts of butanone.

[0047] 3) Coating layer: the aluminum medium changes from solid to gaseous state through resistance heating, and ...

Embodiment 2

[0055] 1) Implantation of glass microbeads: put glass microbeads (5) with a refractive index of 2.2 and a particle size of 80 μm on the PE / paper composite film (11), and then place them in a hot roller at a temperature of 220°C. With the melting of the PE film, the glass beads settle on the PE / paper composite film, and when the PE / paper composite film is cooled, the glass beads are fixed on the PE / paper composite film to realize the implantation of the glass beads;

[0056] 2) Coating the focusing paint concentric with the glass beads on the surface of the glass beads in step 1), and then drying the solvent through an oven to form a focusing layer (4), the thickness of the focusing layer (4) being 5um.

[0057] Focusing paint is made by mixing 60 parts of solvent-based polyurethane resin, 9 parts of aziridine curing agent, 4 parts of silane coupling agent KH-560, 1 part of commercially available wetting agent, 200 parts of ethyl acetate, and 5 parts of kaolin.

[0058] 3) Coat...

Embodiment 3

[0066] 1) Implanting glass beads: place glass beads (5) with a refractive index range of 1.94 and a particle size of 50 μm on the PE / PET composite film (11), and then place them in a hot roller at a temperature of 180°C. As the PE / PET composite film melts, the glass beads settle on the PE film, and when the PE film cools down, the glass beads are fixed on the PE / PET composite film to realize the implantation of the glass beads;

[0067] 2) Coating the focusing paint concentric with the glass beads on the surface of the glass beads in step 1), and then drying the solvent through an oven to form a focusing layer (4), the thickness of which is 3um.

[0068] Focusing paint is made by mixing 60 parts of solvent-based acrylic resin, 5 parts of methyl etherified amino resin, 10 parts of toluene and 3 parts of silicon dioxide.

[0069] 3) Coating layer: Dielectric titanium nitride transforms from solid state to gaseous state through resistance heating, meets the focusing layer (4) and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com