Natural gas combustion synergist, natural gas mixture containing same, and preparation method of natural gas mixture

A synergist and natural gas technology, applied in gas fuel, fuel, petroleum industry, etc., can solve the problems of unsmooth and continuous gas supply, low safety of ignition point, and low total calorific value of combustion, so as to improve combustion speed and combustion efficiency , Improve mixing speed and mixing rate, improve the effect of chemical reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

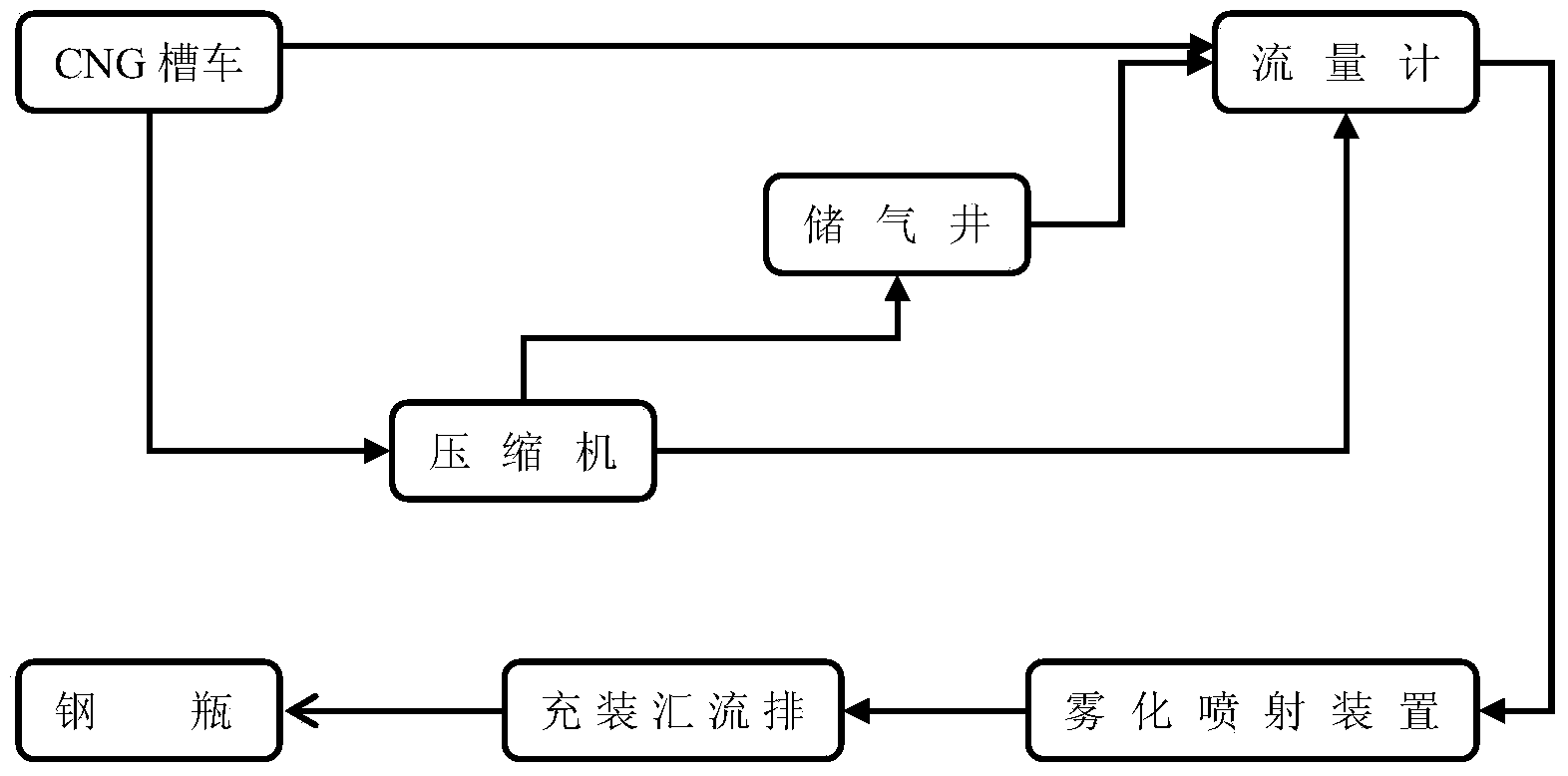

Method used

Image

Examples

Embodiment 1

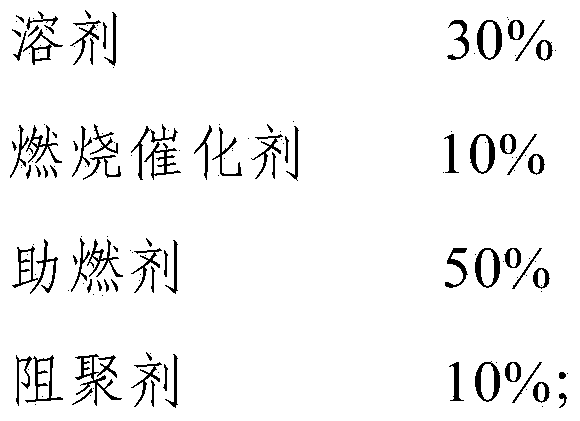

[0038] Components and mass percentages of a natural gas combustion synergist are:

[0039]

[0040] The solvent is the first mixed solvent, that is, the first mixed solvent is composed of acetone, butanone and ethanol, wherein the mass ratio of acetone: butanone: ethanol is 1:4:1; the combustion catalyst is positive Octyl ferrocene; the combustion accelerant is composed of methanol, xylene and higher alcohols, wherein the mass ratio of methanol: xylene: higher alcohols is 3:1:1, and the higher alcohols are C18-C22 carbons Alcohol; the polymerization inhibitor is formed by mixing magnesium naphthenate and steadecatrienyl glyceride according to the mass ratio of 3:2.

Embodiment 2

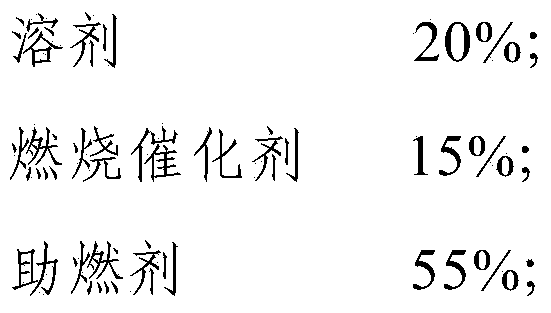

[0042] Components and mass percentages of a natural gas combustion synergist are:

[0043]

[0044]

[0045] The solvent is the first mixed solvent, that is, the first mixed solvent is composed of acetone, butanone and ethanol, wherein the mass ratio of acetone: butanone: ethanol is 1:2:1; the combustion catalyst is positive Octyl ferrocene; the combustion accelerant is composed of methanol, xylene and higher alcohols, wherein the mass ratio of methanol: xylene: higher alcohols is 8:2:1, and the higher alcohols are C20-22 carbons Alcohol; the polymerization inhibitor is formed by mixing magnesium naphthenate and steadecatrienyl glyceride according to the mass ratio of 3:2.

Embodiment 3

[0047] Components and mass percentages of a natural gas combustion synergist are:

[0048]

[0049] The solvent is the fourth mixed solvent, and the fourth mixed solvent is composed of turpentine, light oil, butanone and ethanol, wherein the mass ratio of turpentine: light oil: butanone: ethanol is 5:5:9:5; The combustion catalyst is n-octyl ferrocene; the combustion accelerant is composed of methanol, xylene and higher alcohol, wherein the mass ratio of methanol:xylene: higher alcohol is 7:2:1, and the higher alcohol It is an alcohol with C20-22 carbons; the polymerization inhibitor is formed by mixing magnesium naphthenate and octadecatrienylglyceride in a mass ratio of 3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com