Drawing-like stainless steel clad steel plate

A technology of composite steel plate and stainless steel, applied in the field of steel plate, can solve the problems of unsatisfactory anti-fingerprint effect and high product cost, and achieve the effect of beautiful appearance, improved productivity, and increased texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

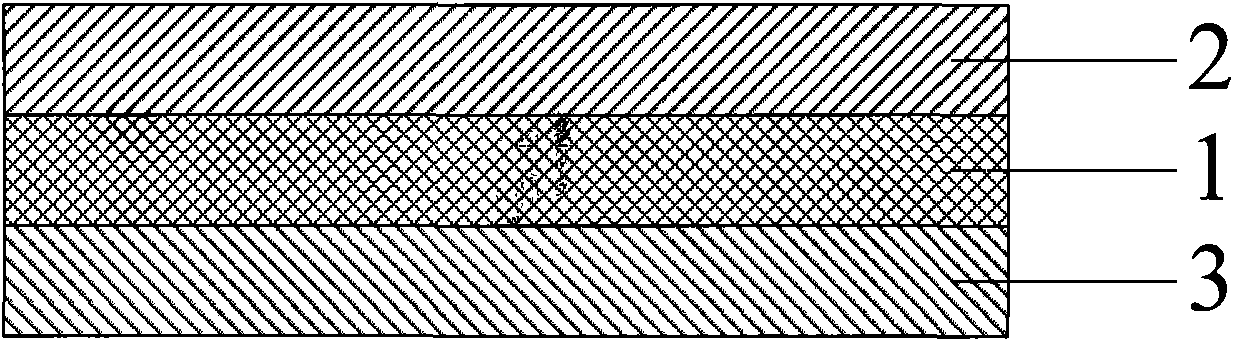

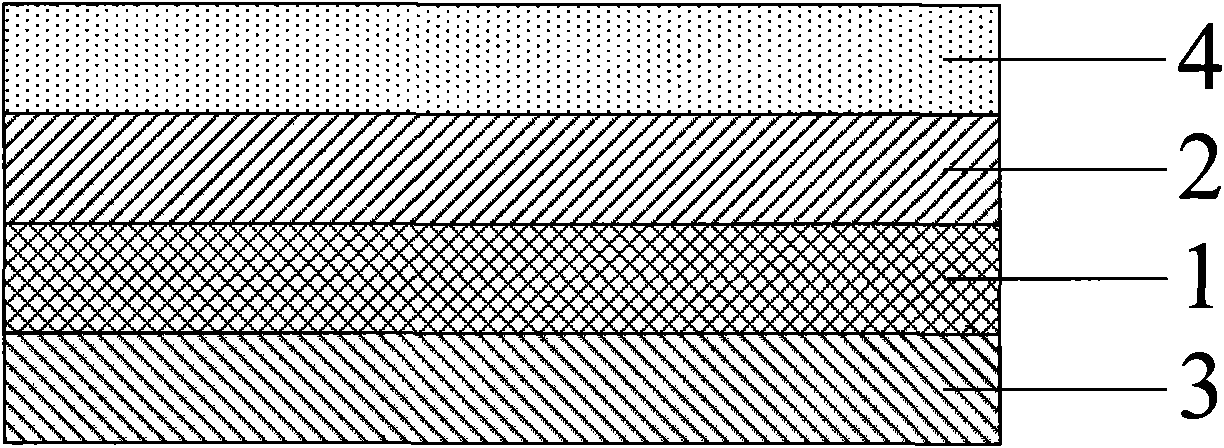

[0016] Such as figure 1 As shown, the brushed stainless steel composite steel plate mainly includes a steel plate 1, and a composite film layer 2 is covered and bonded on the steel plate 1, and the composite film layer 2 is polyethylene terephthalate / printing layer / polyvinyl chloride (PET / The composite film layer composed of printing layer / PVC), the thickness of the composite film layer is usually 0.11-0.15mm, and a back paint layer 3 is also provided on the back of the steel plate layer 1 . Additionally, if figure 2 A protective film layer 4 is also covered and bonded on the composite film layer 2 .

[0017] The steel plate is made of cold-rolled steel plate, which can play the role of decoration, protection and beauty after bonding the composite film. The process is simple and the operation is convenient. In particular, the VCM imitation brushed stainless steel composite steel plate can replace the stainless steel patterned plate, and can be used for deep drawing and str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com