Building method of filled wall body for gob-side entry retaining of large-inclination coal seam

A technology of filling walls with a large inclination angle, which is applied in the direction of filling, earthwork drilling, safety devices, etc., which can solve the problems of low strength of filling materials, high labor intensity, and slow construction speed, and achieve saving of support materials and filling materials , high labor efficiency and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

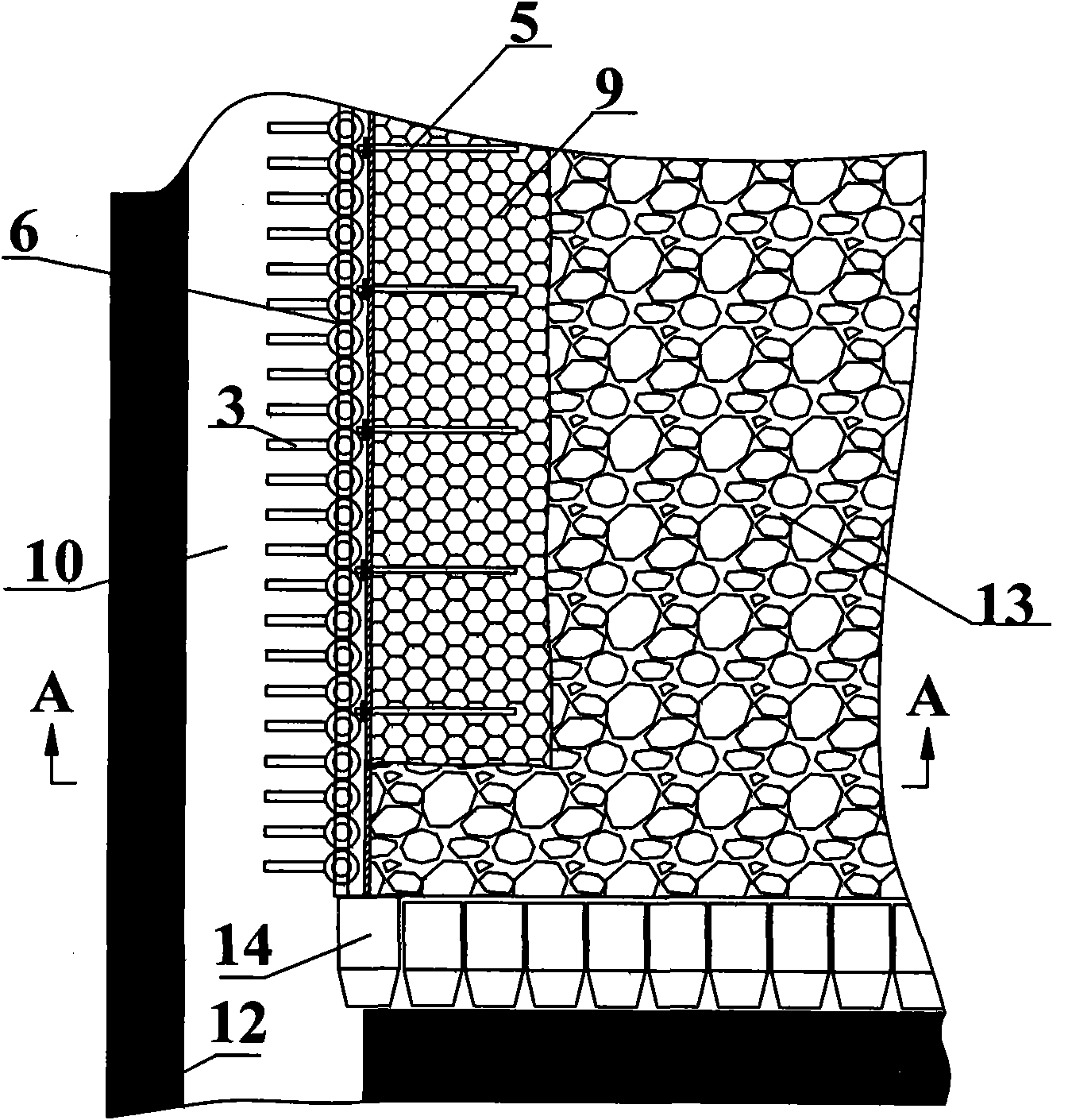

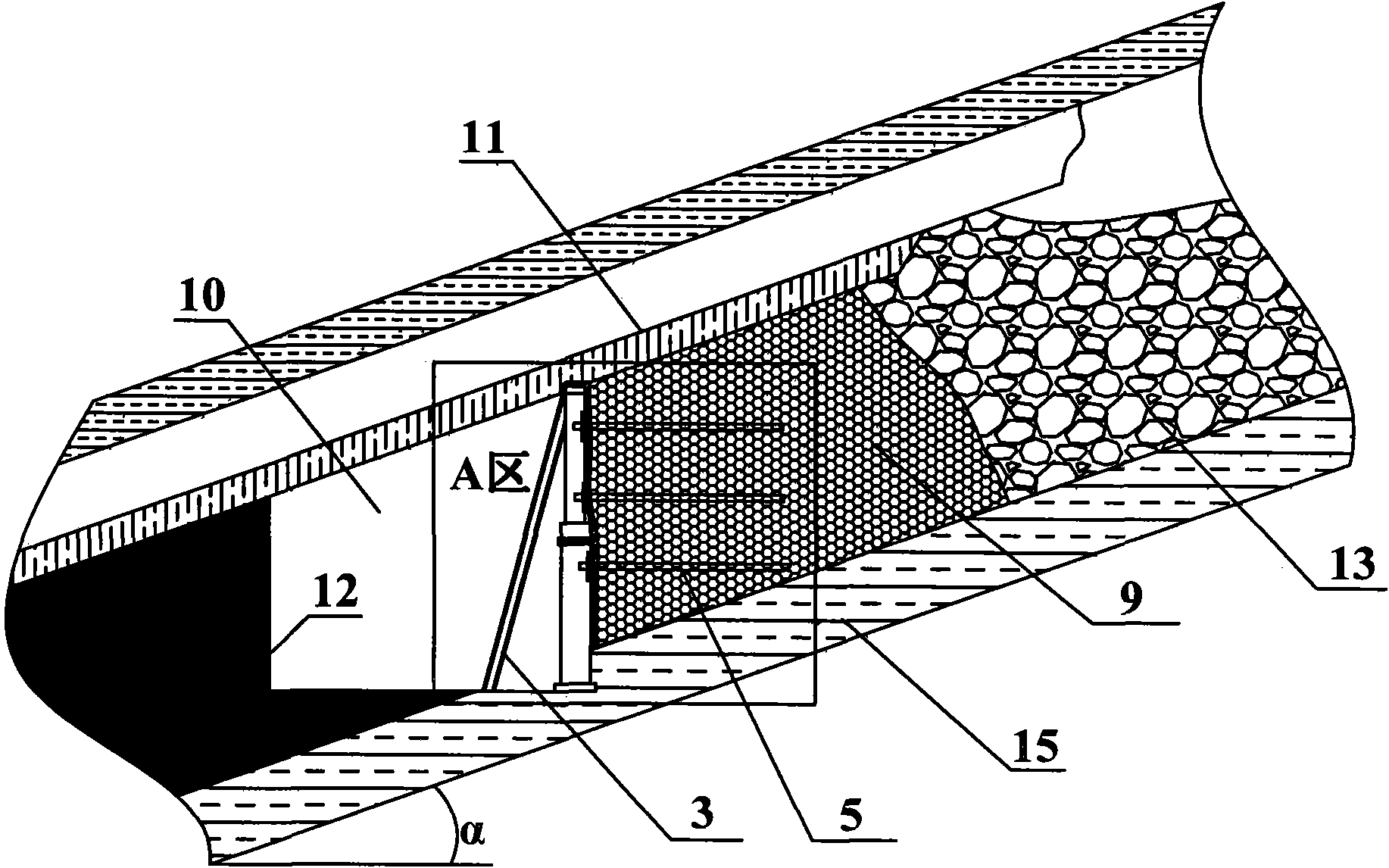

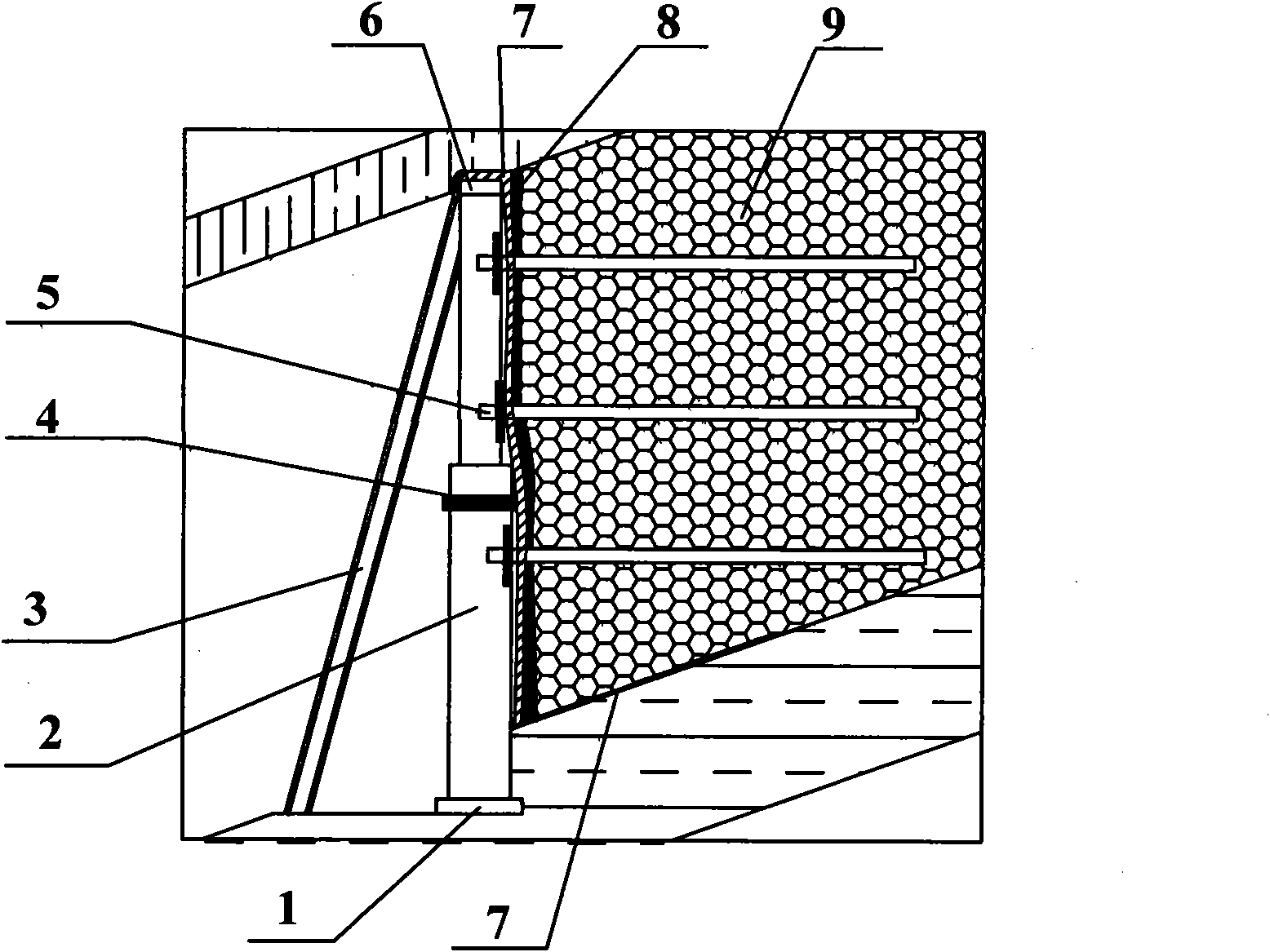

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0017] In the present invention, in the mining area of coal seam 12 with a large inclination angle of coal seam α > 20°, the gangue interception structure of the goaf is first constructed, and at the same time, the grouting anchor is pre-buried, and the gangue falling down in the goaf falls to the gangue under the action of its own weight After intercepting the blocking structure and gradually accumulating to form a stable gangue wall, the lagging working face is used to inject grout into the gangue wall at a certain distance, and the gangue wall is cemented and reinforced into a complete filling wall. Specific steps are as follows:

[0018] 1. Advance the hydraulic support 14 of the mining face by a cut-off depth (about 0.8m), follow the hydraulic support 14 of the mining face and erect dense single pillars 2 with a spacing of 300mm on the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com