Water-soluble high-concentration organic-inorganic compound fertilizer for trickle and sprinkling irrigation and preparation method thereof

A water-soluble organic matter and compound fertilizer technology, applied in the direction of organic fertilizers, inorganic fertilizers, alkaline orthophosphate fertilizers, etc., can solve the problems of being unable to provide organic matter for improving soil plant growth, easily clogging irrigation and fertilization systems, and poor solubility , to achieve the effect of enhancing crop resistance, improving crop quality and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

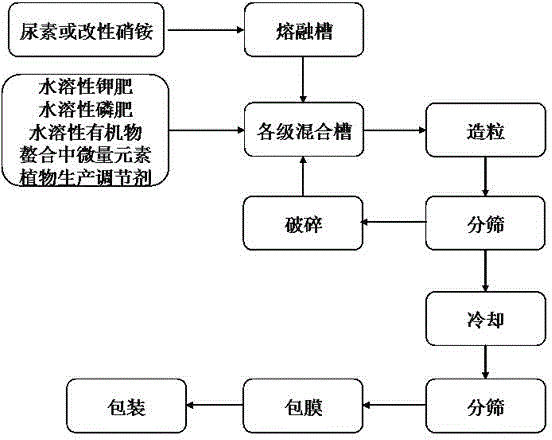

[0032] Prepare the fertilizer as follows: by weight, 600Kg of urea, 100Kg of industrial grade monoammonium phosphate, 45Kg of potassium sulfate, 200Kg of water-soluble potassium fulvic acid, 40Kg of water-soluble ammonium humate, 10Kg of trace elements in water-soluble compound chelation, Compound sodium nitrophenolate 5Kg.

[0033] Fertilizer preparation: Lift urea, industrial-grade monoammonium phosphate, potassium sulfate, water-soluble potassium fulvic acid, and water-soluble ammonium humate into the silo at the top of the tower, and the urea is metered into the melting tank Melt into urea solution and overflow to the mixing tank. Potassium sulfate and potassium dihydrogen phosphate are metered into the primary mixing tank. Water-soluble potassium fulvic acid, water-soluble ammonium humate, water-soluble compound chelated trace elements and compound Sodium nitrophenolate is metered into the secondary mixing tank, chelated and mixed, and then enters the granulator for spray...

Embodiment 2

[0035] Prepare the fertilizer as follows: by weight, ammonium nitrate phosphorus 675Kg, potassium dihydrogen phosphate 60Kg, potassium sulfate 35Kg, water-soluble potassium fulvic acid 215Kg, water-soluble compound chelated trace elements 10Kg, diethyl hexanoate 5Kg.

[0036] Fertilizer preparation: Lift ammonium nitrate phosphorus, potassium dihydrogen phosphate, potassium sulfate, and water-soluble potassium fulvic acid into the silo at the top of the tower with a lifter, and ammonium nitrate phosphorus is metered into the melting tank to be melted into ammonium nitrate The solution overflows to the mixing tank. Potassium sulfate and potassium dihydrogen phosphate are metered into the primary mixing tank, and water-soluble potassium fulvic acid, water-soluble compound chelated trace elements and diethyl aminohexanoate are metered into the secondary mixing tank. After chelation and mixing, it enters the granulator for spray granulation, and after cooling, screening and coating...

Embodiment 3

[0038] Prepare the fertilizer as follows: by weight, 400Kg of urea, 228Kg of industrial grade monoammonium phosphate, 150Kg of potassium sulfate, 215Kg of water-soluble potassium fulvic acid, 5Kg of trace elements in water-soluble compound chelation, and 2Kg of diethyl hexanoate.

[0039] Fertilizer preparation: Lift urea, industrial grade monoammonium phosphate, potassium sulfate, and water-soluble potassium fulvic acid into the silo at the top of the tower with a lifter, and the urea is metered into the melting tank to melt into a urea solution and overflow To the mixing tank, potassium sulfate and industrial grade monoammonium phosphate are metered into the first-level mixing tank, water-soluble potassium fulvic acid, trace elements in water-soluble compound chelation and diethyl aminoethyl hexanoate are metered into the second-level mixing tank, chelating, After mixing evenly, enter the granulator for spray granulation, after cooling, sieving and film coating, it will be pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com