Garlic planter

A technology of planter and garlic, applied in the directions of sowing, converting sensor output, measuring device, etc., to achieve the effect of reducing production cost, improving labor efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

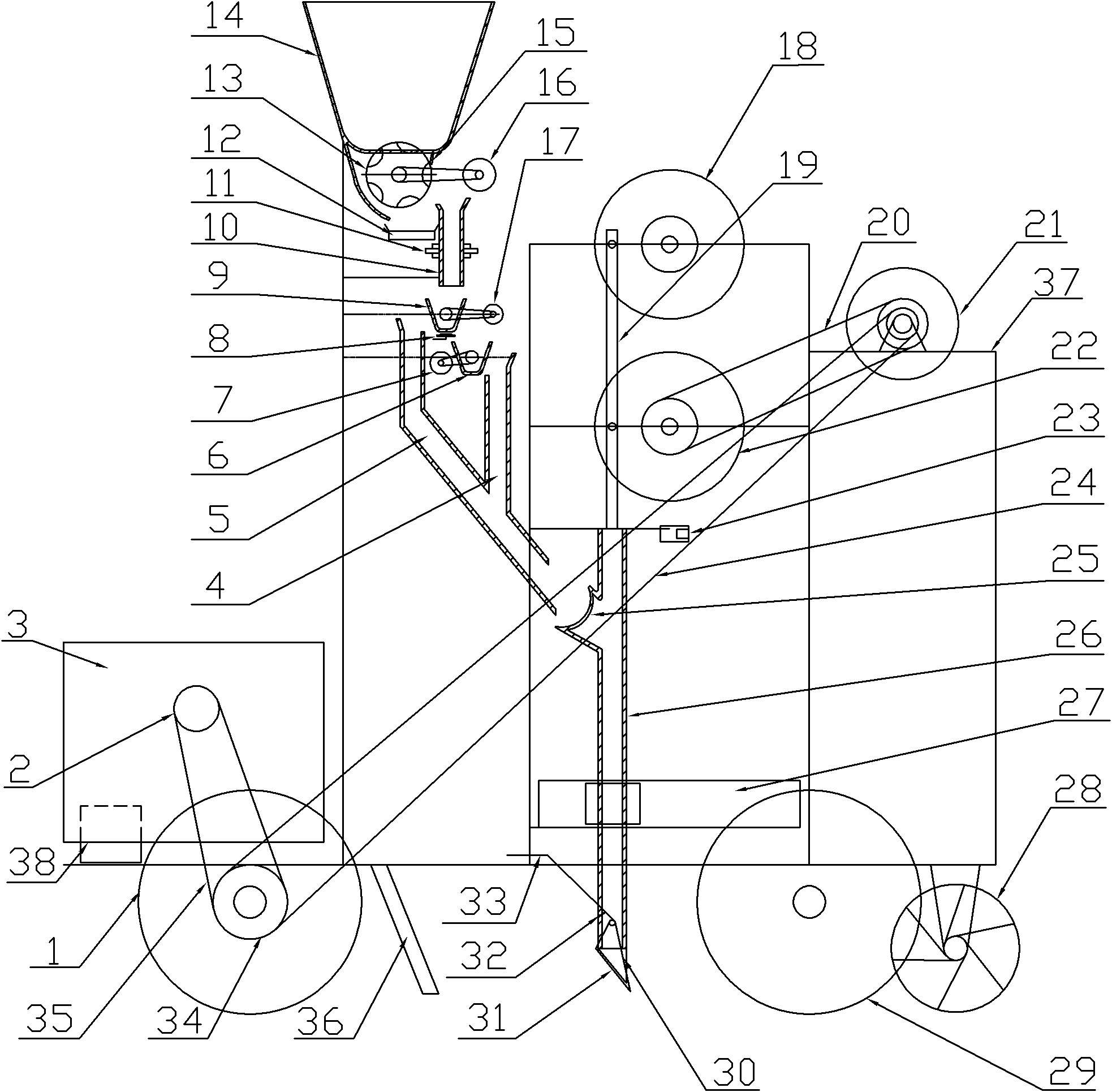

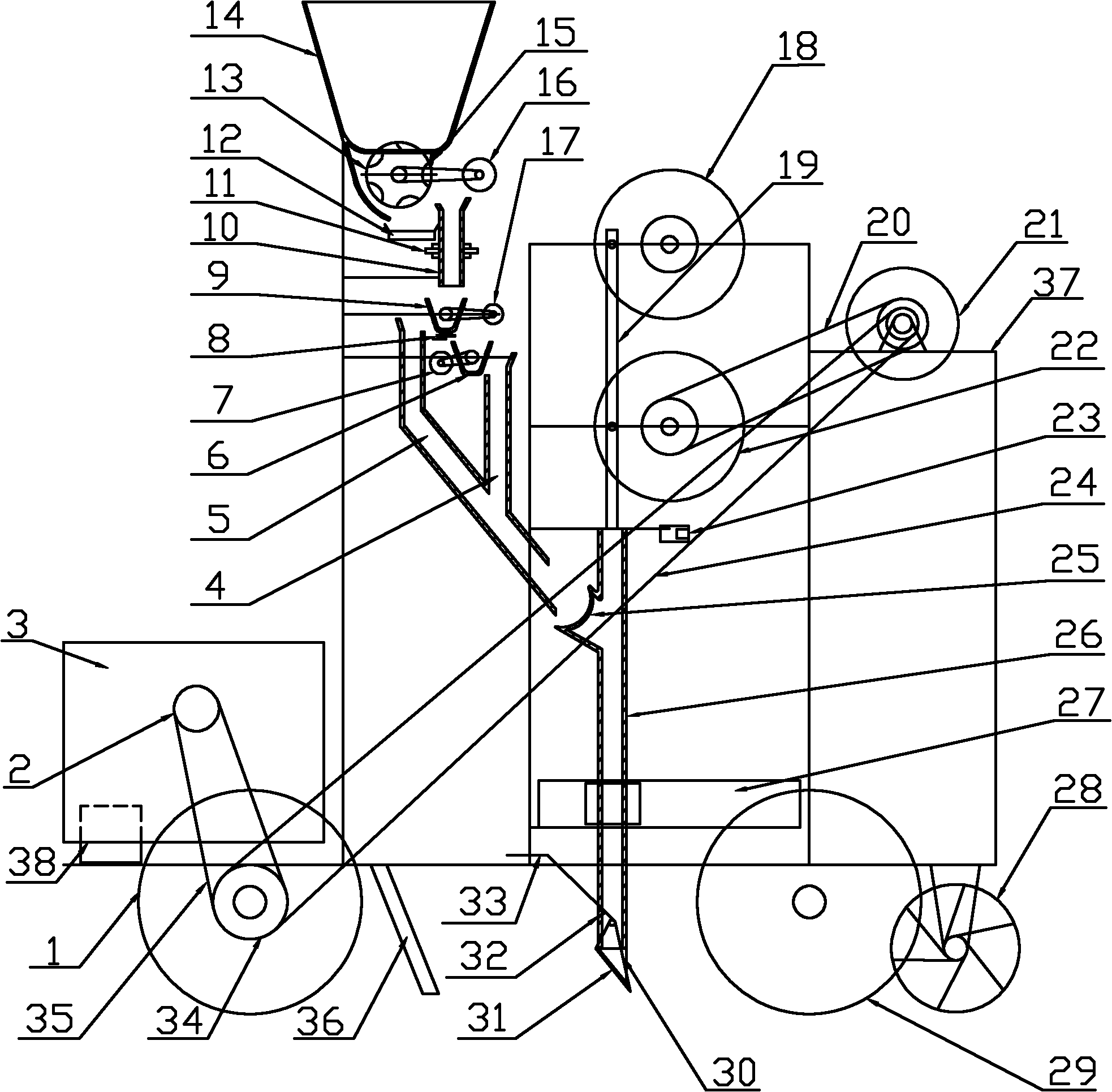

[0015] Refer to the attached figure 1 A kind of garlic seeder of the present invention is described in detail below.

[0016] A kind of garlic planter of the present invention, its structure comprises frame 37, soil covering mechanism 36, soil crushing device 28, front wheel 29, rear wheel 1, seed box 14 and power transmission mechanism, described soil covering mechanism 36, soil crushing device Device 28, front wheel 29 and rear wheel 1 are respectively arranged at the bottom of frame 37, and described power transmission mechanism includes power box 3, power wheel 2, sprocket wheel 34 and the 3rd chain 35 and speed change mechanism 21, and described chain The wheel 34 is connected to the transmission mechanism 21 through the second chain 24, the power wheel 2 is connected to the power box 3, the power wheel 2 is connected to the sprocket 34 through the third chain 35, and the sprocket 34 Coaxial with the rear wheel 1, the described seed box 14 and the power box 3 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com