Assembly connection structure and method of coupling beams of shear walls of assembly concrete frame shear structure

A frame-shear structure and connection structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of heavy concrete wet work, difficult to guarantee building quality, unfavorable energy saving and emission reduction, etc., to achieve easy production and transportation, Reduced assembly cost and reasonable weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

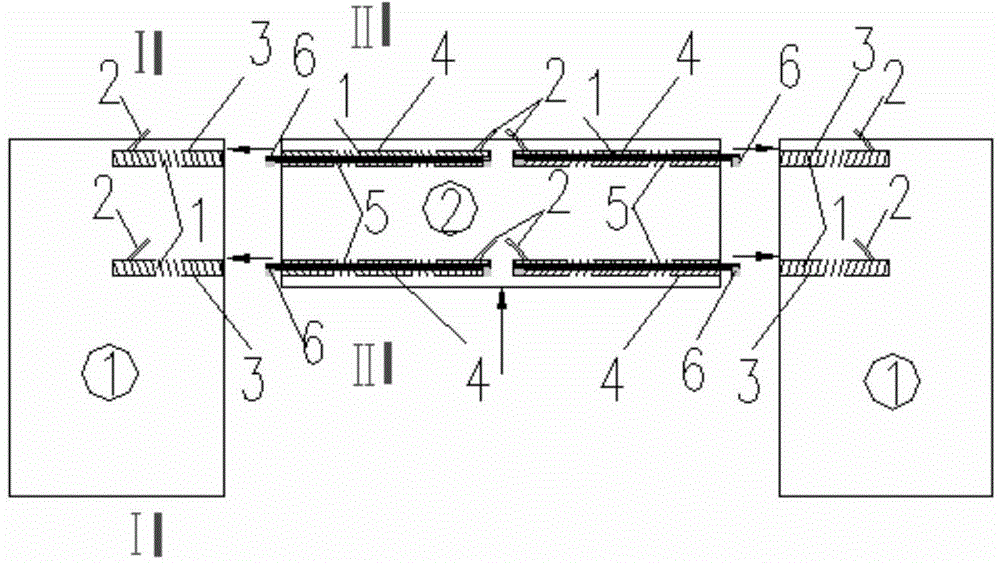

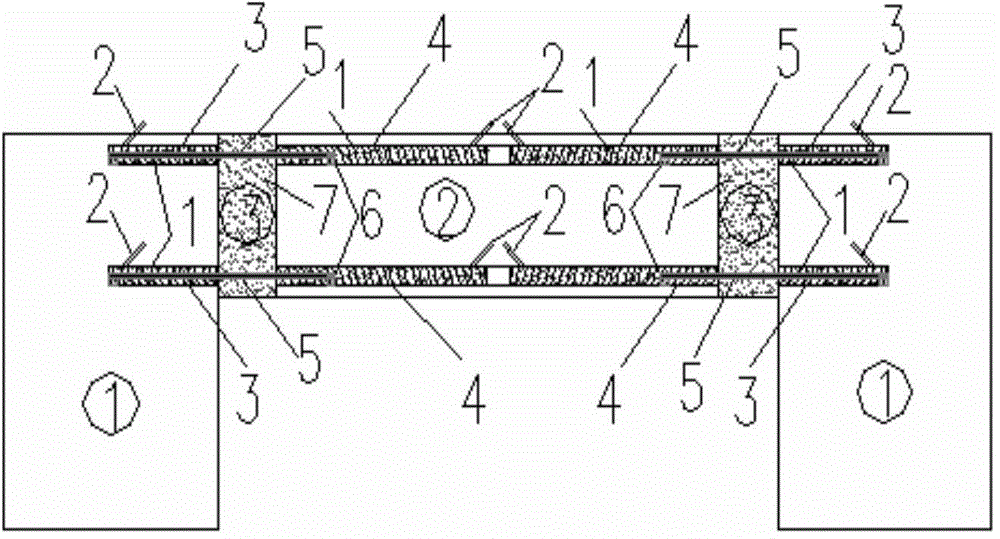

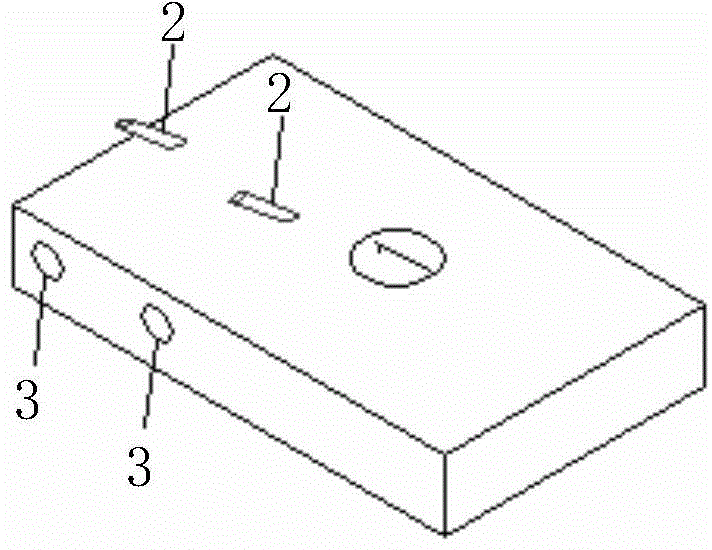

[0038] Figure 1 to Figure 5 As shown, the splitting and assembling connection structure and assembling connection method of the shear wall connecting beams of the fabricated concrete frame-shear structure of the present invention include two specific embodiments, which are specifically as follows:

[0039] (1) When the connecting beam of the shear wall in the prefabricated concrete frame-shear structure is longer (the length of the connecting beam is greater than twice the equivalent steel anchoring length), the connecting beam is split at the connecting position of the shear wall at both ends of the connecting beam. A structural split assembly system consisting of two prefabricated shear walls (hereinafter referred to as prefabricated walls①) and a prefabricated shear wall connecting beam (hereinafter referred to as prefabricated connecting beams②) is formed. In order to realize the connection between the precast wall ① and the precast connecting beam ②, there are reserved hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com