Heat-preservation wall body of wood-frame shear wall

A technology for thermal insulation walls and shear walls, applied to thermal insulation, walls, building components, etc., can solve the problems of low industrial production level, poor wall thermal insulation performance, and invisible wooden components, so as to improve construction efficiency and ensure Resistant to lateral forces, reducing the effect of wet work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

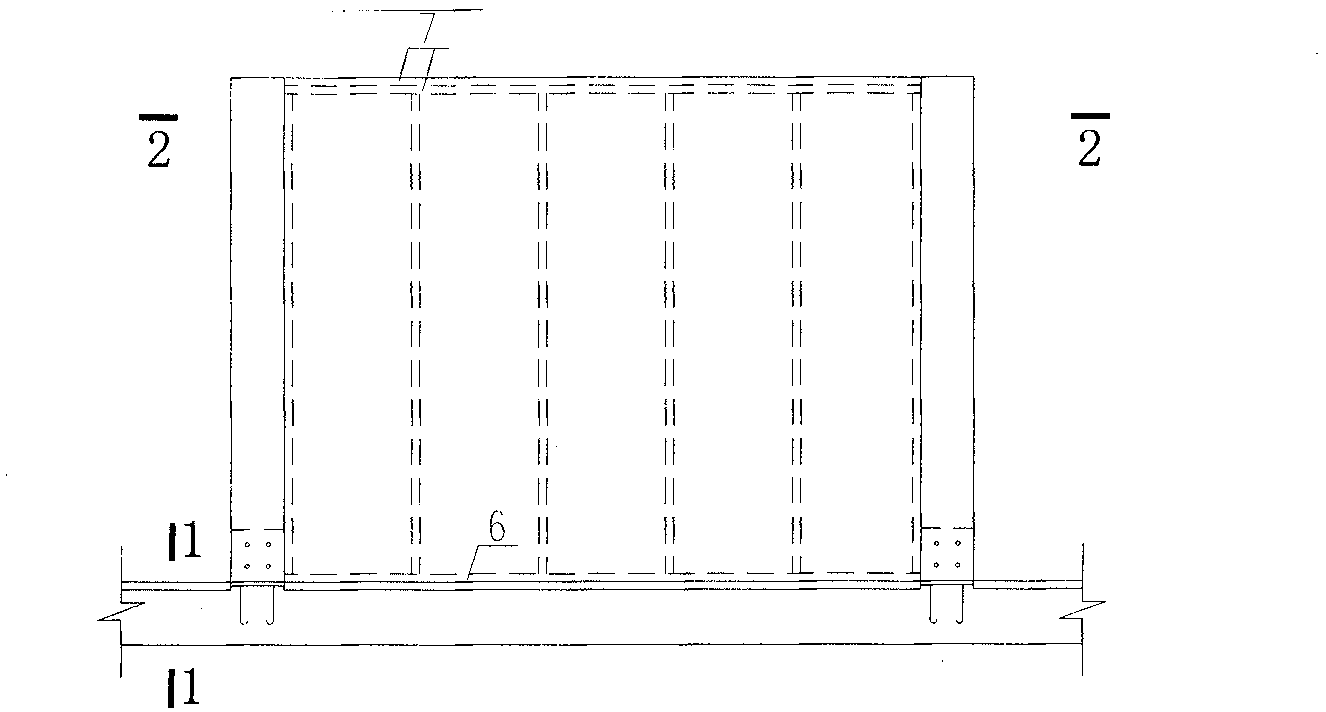

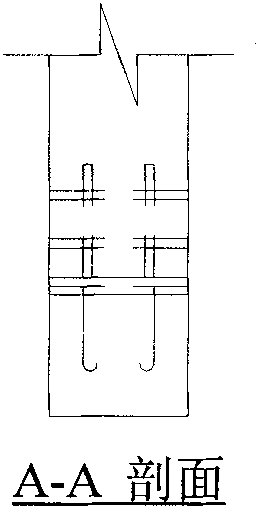

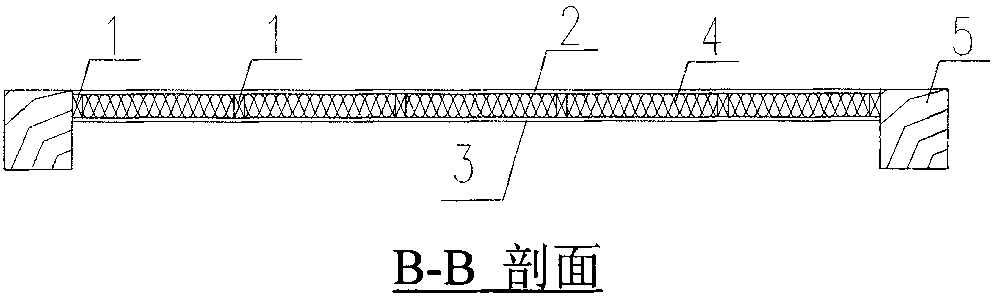

[0017] Embodiment 1: Assembled wooden frame-shear-resistant thermal insulation wall of the present invention. The specific size of the wall pieces is determined according to the building layout and structural bearing capacity requirements. The distance between the middle gauge timbers is 400-600mm as the modulus, and local adjustments are made by the stud columns of the end walls on both sides. The horizontal distance between the adjacent wall studs 1 is 400-600 mm, and the wall studs 1 on both sides are connected with the wooden frame columns 5 with nails; the wooden base structural board 2 is covered on the outside of the thermal insulation wall, and is connected with the wall studs 1 and the top beam plate. 7. The bottom beam plate 6 is connected by nails, and is flush with the outside of the wooden frame column 5; the inner side of the wallboard is covered with gypsum board 3 (when the lateral force is large, the wood-based structural plate can also be used according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com