Assembled type steel frame concrete box type unit structure system and construction method thereof

A box structure and unit structure technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems such as the inability to ensure the tightness of the joints of the structure, the single function of the functional partition of the building, and the low energy saving efficiency of the thermal insulation layer. , to achieve the effect of improving non-functional partitions, reducing wet operations, and improving overall use functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

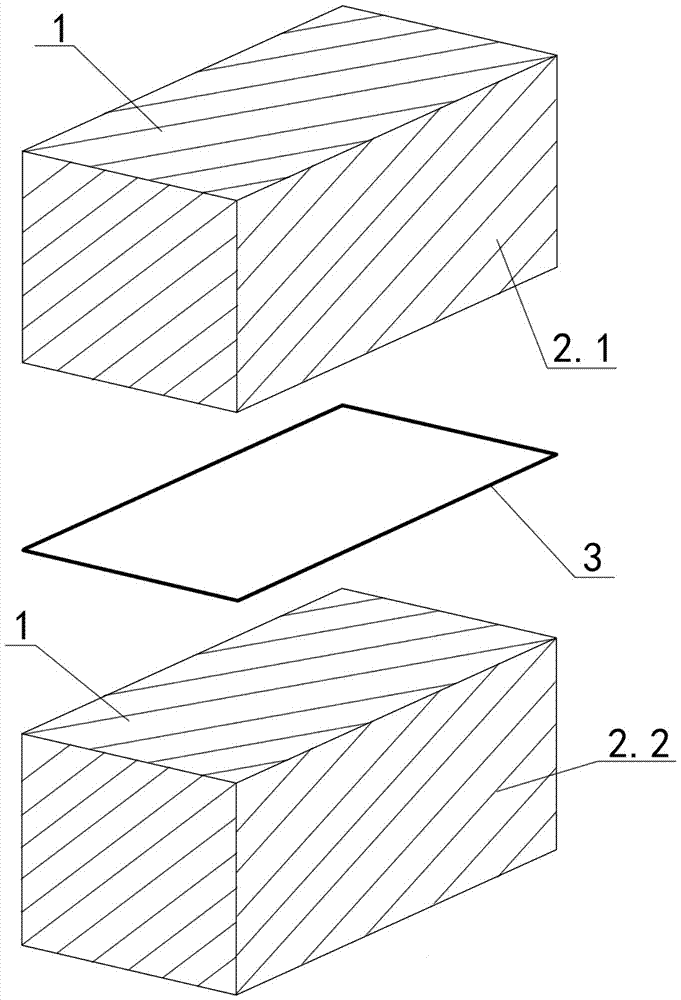

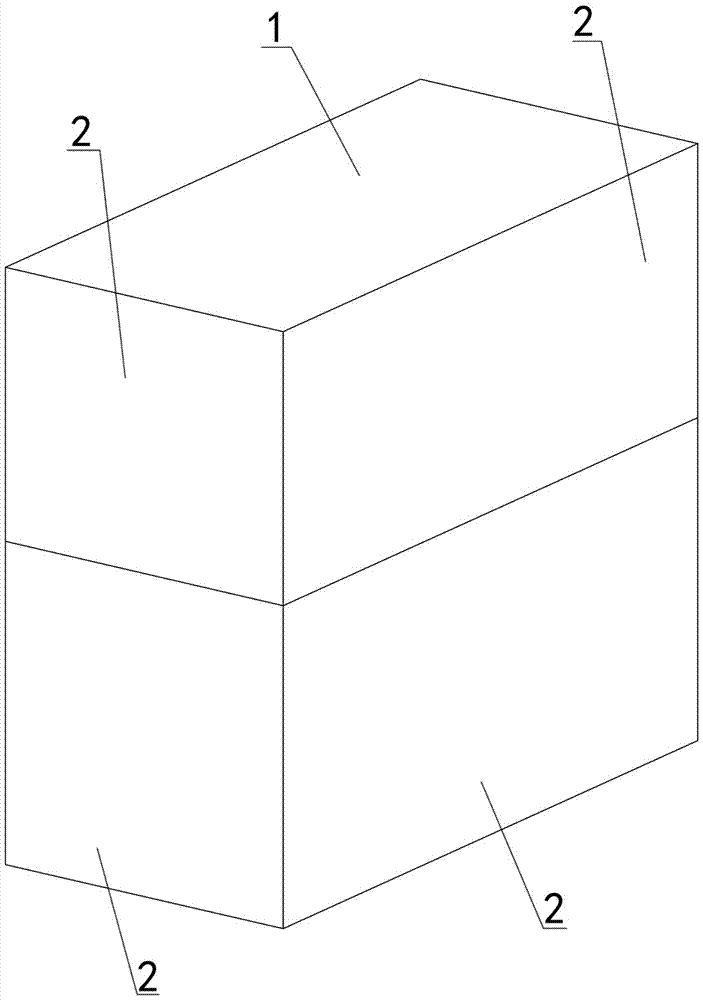

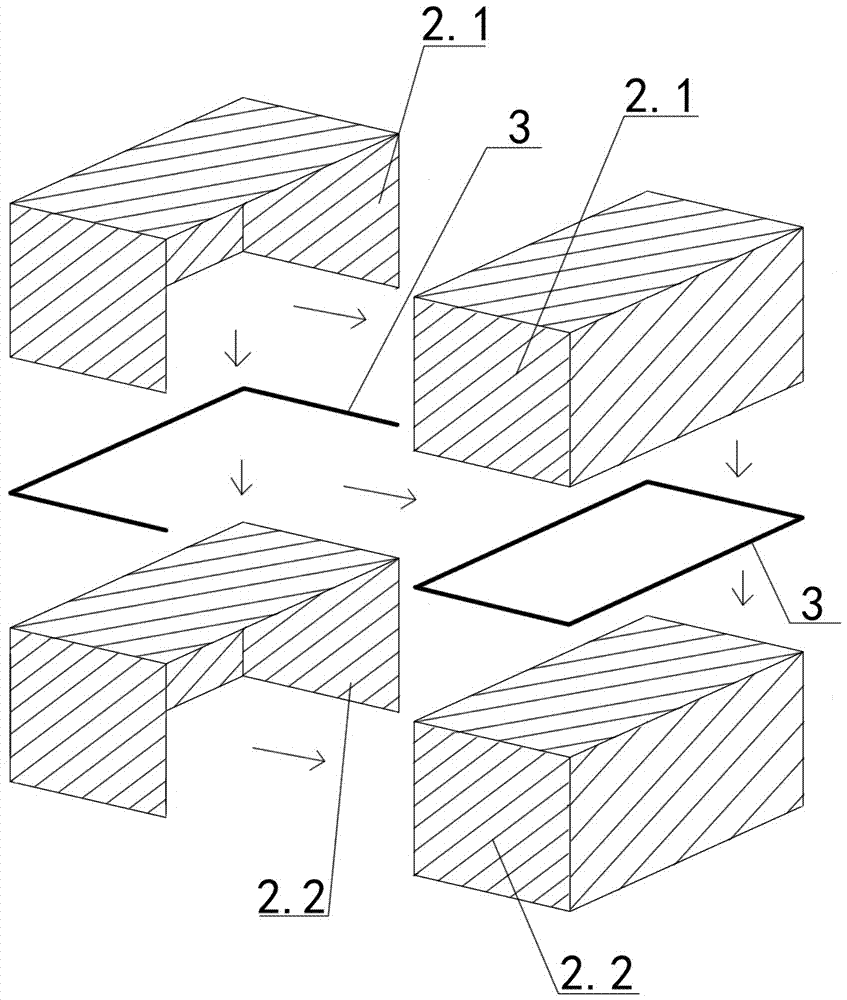

[0049] Embodiment one sees Figure 1a-1b As shown, a prefabricated steel frame concrete box-type unit structure system includes a foundation and an above-ground structure connected to the foundation. The above-ground structure includes at least two layers of structures vertically spliced by steel frames. Each layer of structure includes a box The box-type structural unit is a bell-type five-sided box-type structural unit composed of one roof floor component 1 and four wall components 2 cast integrally.

[0050] see Figure 3-7 As shown, the steel frame is a groove-shaped horizontal steel frame 3 that is preset at the splicing position of the upper and lower wall members and embedded along the inner side of the upper wall member 2.1. The groove of the same box-type structural unit The groove-shaped horizontal steel frame 3 is connected as a whole, and the opening of the channel-shaped horizontal steel frame 3 faces indoors, including a horizontal upper flange plate 3.1, a ve...

Embodiment 2

[0055] Embodiment two see Figure 2a-2b As shown, the difference from Embodiment 1 is that this prefabricated steel frame concrete box-type unit structure system includes at least two upper and lower layers of structures that are vertically spliced by steel frames, and each layer structure includes two box-type structural units , the box-type structural unit includes a bell-shaped five-sided box-type structural unit composed of one roof floor member 1 and four wall members 2 cast in one piece, and the box-type structural unit also includes a top plate cast in one piece The bell-jar wall-less box-type structural unit composed of the floor member 1 and the three wall-surface members 2, the roof floor member of the bell-jar wall-less box-type structural unit is a one-way plate,

[0056] Each floor structure includes at least two or more horizontally spliced box-type structural units. In the structural system of other embodiments, the bell-shaped five-sided box-type structural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com