Connection structure of fabricated steel structure building enclosure outer wall and H-shaped steel beam

A technology of building envelope and H-shaped steel, which is applied in the direction of building components, building structures, buildings, etc., to achieve the effects of ensuring construction quality, reducing wet work on site, and avoiding thermal expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings and specific embodiments.

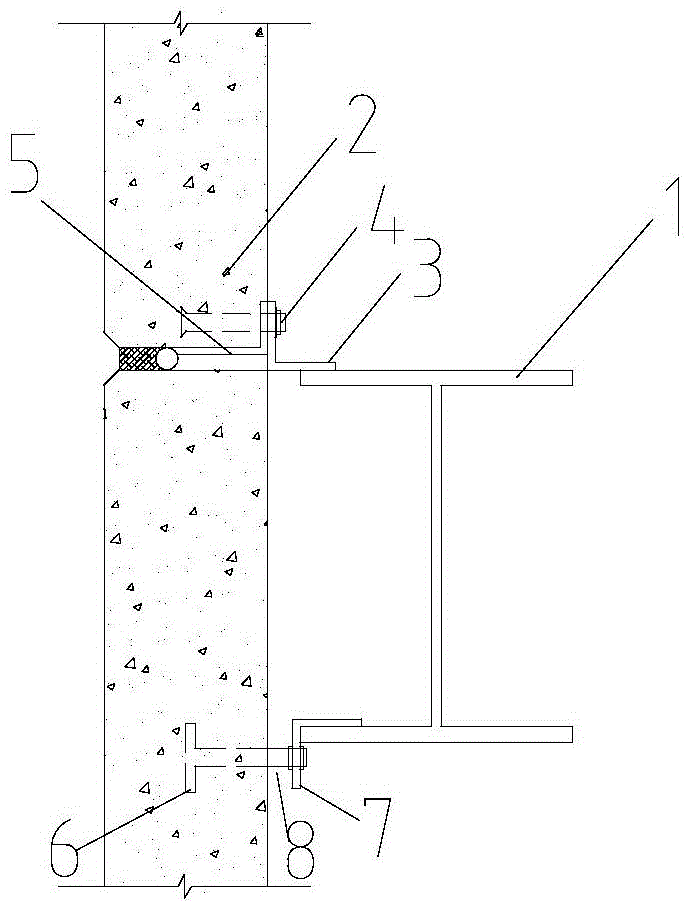

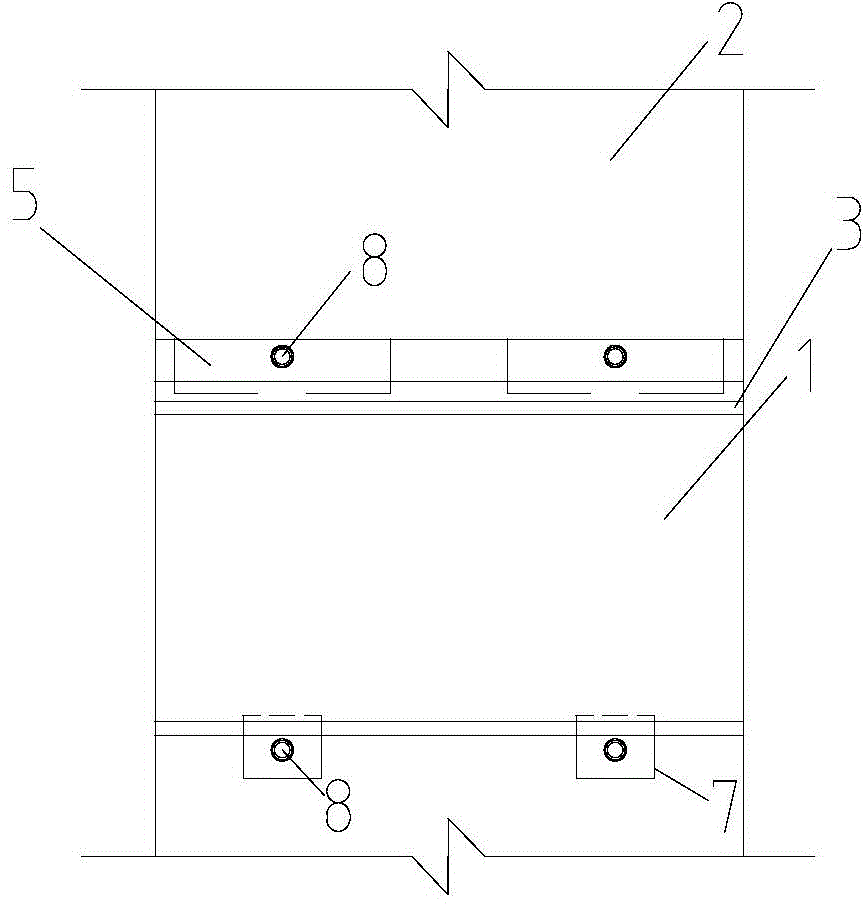

[0022] Combine figure 1 with figure 2 , The connecting structure of the outer wall of the prefabricated steel structure building of the present invention and the H-shaped steel beam, the outer wall plate 2 is made of autoclaved aerated concrete, and its lower end is fixedly connected with the upper flange of the H-shaped steel beam 1. It is fixedly connected to the lower flange of the H-shaped steel beam 1. The connection method is:

[0023] In the factory, a full-length angle steel 3 is welded on the upper flange of the H-beam 1; two steel "┗"-shaped pallets 5 are welded symmetrically on the back of the angle steel 3; on the lower wing of the H-beam 1 Two angle steel adapters 7 are welded corresponding to the upper and lower sides of the pallet 5; two high-strength friction bolts A4 are embedded on the lower end of the outer wall panel corresponding to the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com