Connection joint of lower bearing prefabricated concrete external wall and steel beam

A technology of precast concrete and connecting nodes, which is applied in the direction of building and building structure, can solve the problems such as the inability to use wet connecting nodes and the short development time of the prefabricated exterior wall system, so as to avoid the overall calculation, improve the construction efficiency and quality, The effect of convenient construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

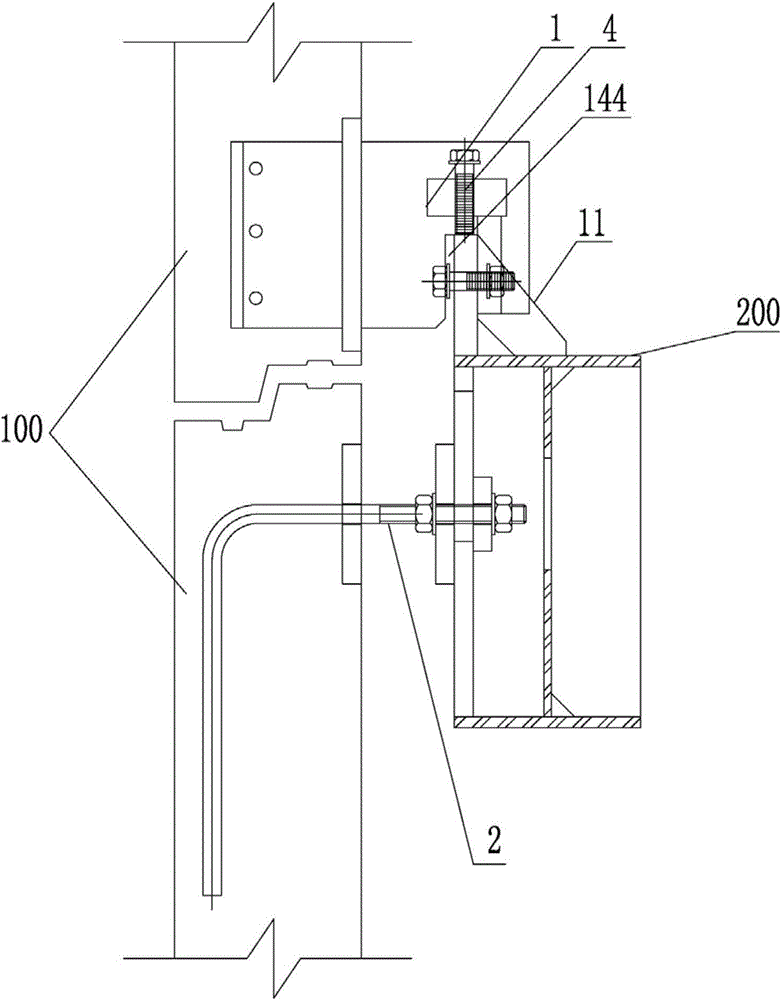

[0036] Please refer to the attached figure 1 to attach Figure 4 , and the attached Figure 8 As shown, the present invention is a connection node between a lower load-bearing precast concrete exterior wall and a steel beam, which consists of a precast concrete exterior wall 100, a steel beam 200, a lower load-bearing node 1 and an upper connection node 2.

[0037] Wherein, the prefabricated concrete exterior wall 100 adopts single-layer wallboard or double-layer wallboard sandwiching thermal insulation cotton. The steel beam 200 is an I-shaped steel beam, a square tube beam or a box beam.

[0038] The upper end of the lower bearing node 2 is pre-embedded in the precast concrete outer wall 100 , and the lower end is welded on the upper flange of the steel beam 200 . One end of the upper connection node 2 is pre-embedded in the precast concrete outer wall 100 , and the other end is anchored on the steel beam 200 .

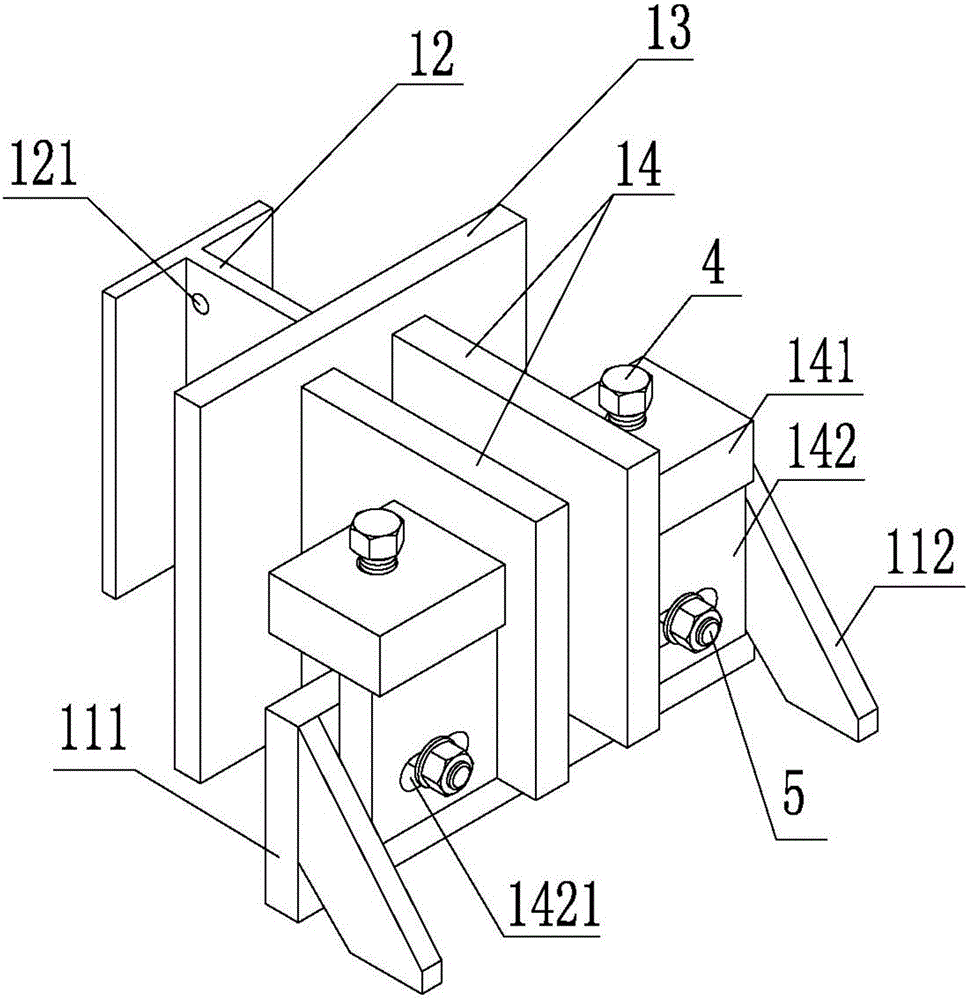

[0039] The lower load-bearing node 1 includes a load-beari...

Embodiment 2

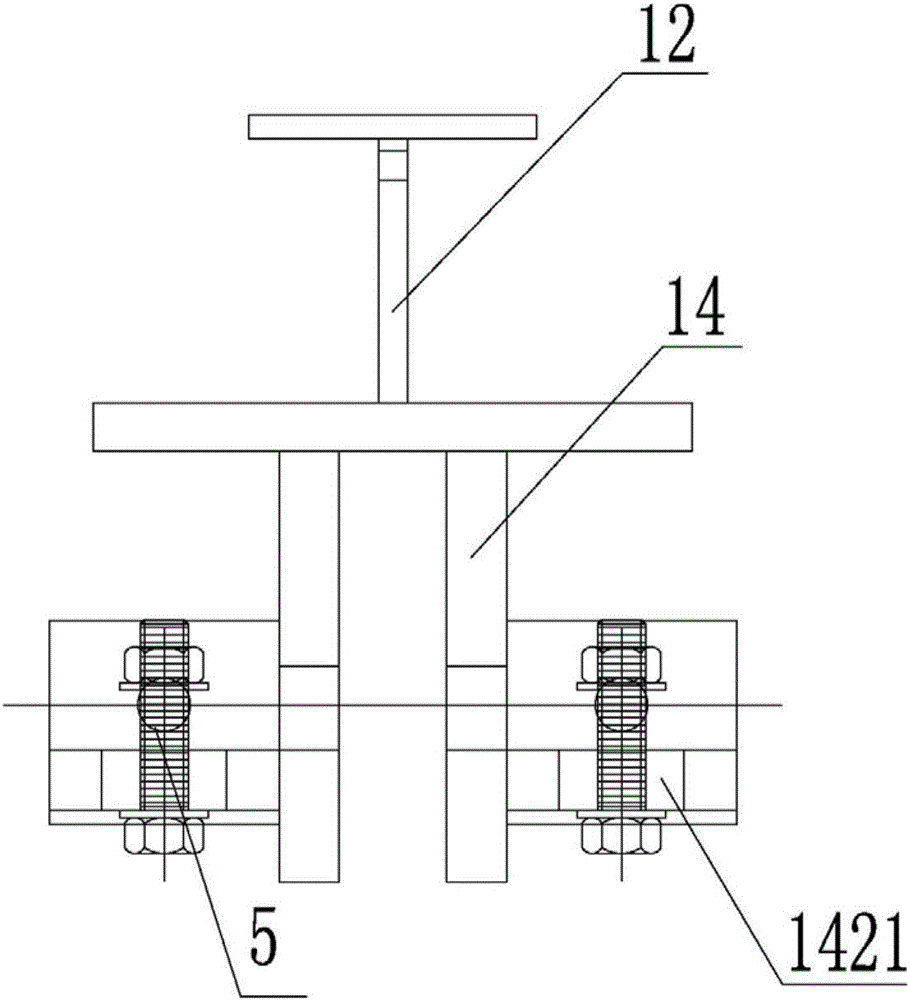

[0048] Please refer to the attached Figure 5 to attach Figure 7 , the present invention is a second embodiment of the lower load-bearing node 1 of the connection node between the lower load-bearing prefabricated concrete outer wall and the steel beam. The difference between it and the first embodiment is that one side of the vertical steel plate 111 is opened A vertical oblong hole 1111; a vertical adjustment plate 141 is respectively welded on both sides of the buckle steel plate 14, and each vertical adjustment plate 141 is screwed with a vertical high-strength bolt 4, and the vertical high-strength bolt 4 leans against the The top of vertical steel plate 111; Weld level adjustment plate 142 on each vertical adjustment plate 141, offer horizontal oblong hole 1421 on one of them horizontal adjustment plate 142, offer round hole 1422 on another level adjustment plate 142; Described vertical steel plate 111 is connected to the vertical adjustment plate 141 through a horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com