A connection node between an upper load-bearing precast concrete exterior wall and a steel beam

A technology of prefabricated concrete and connecting nodes, applied in the direction of walls, buildings, building components, etc., can solve the problems of short development time of prefabricated exterior wall systems and the inability to use prefabricated steel structure buildings for wet connection nodes, so as to avoid overall calculation and improve Construction efficiency and quality, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

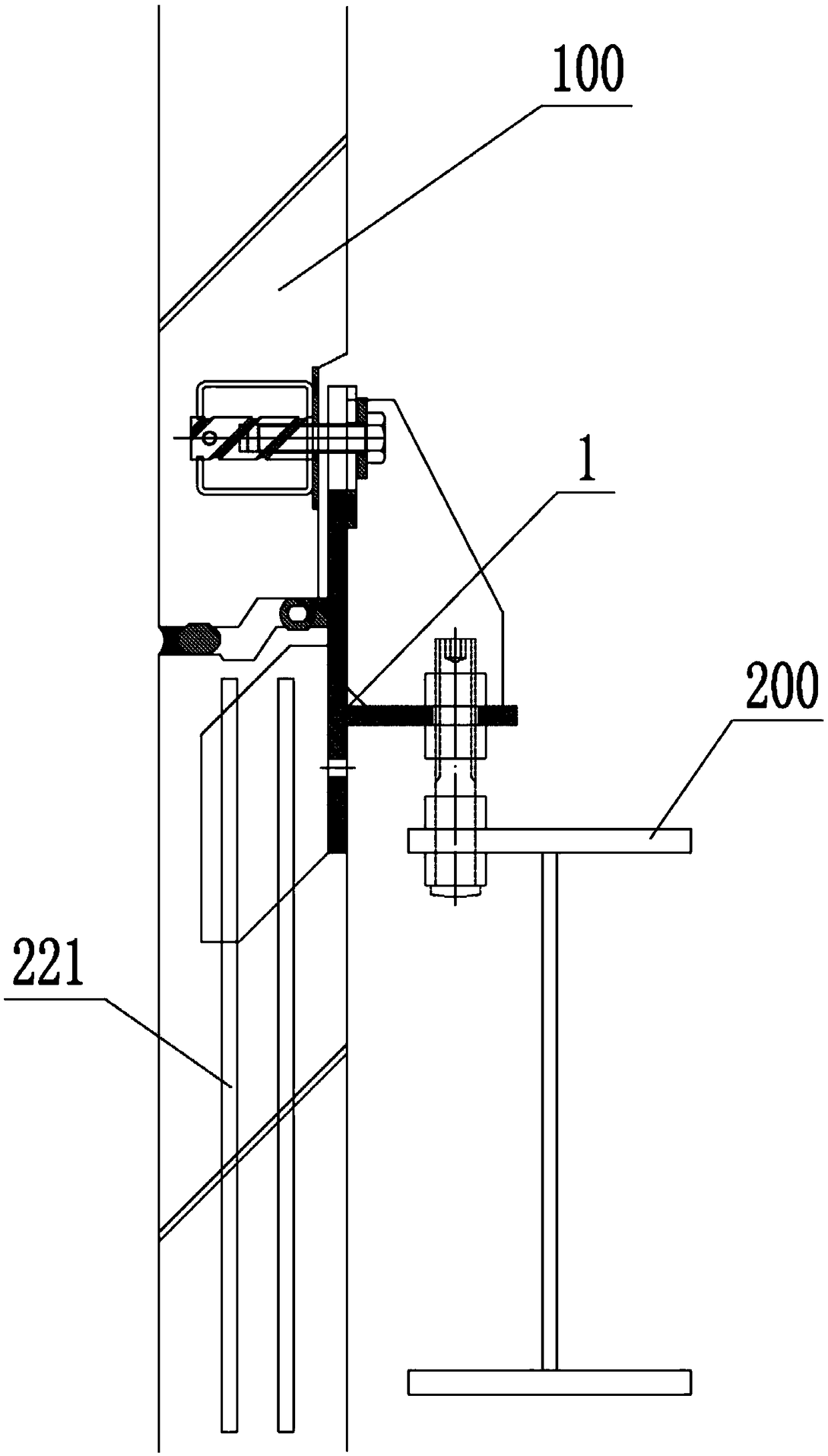

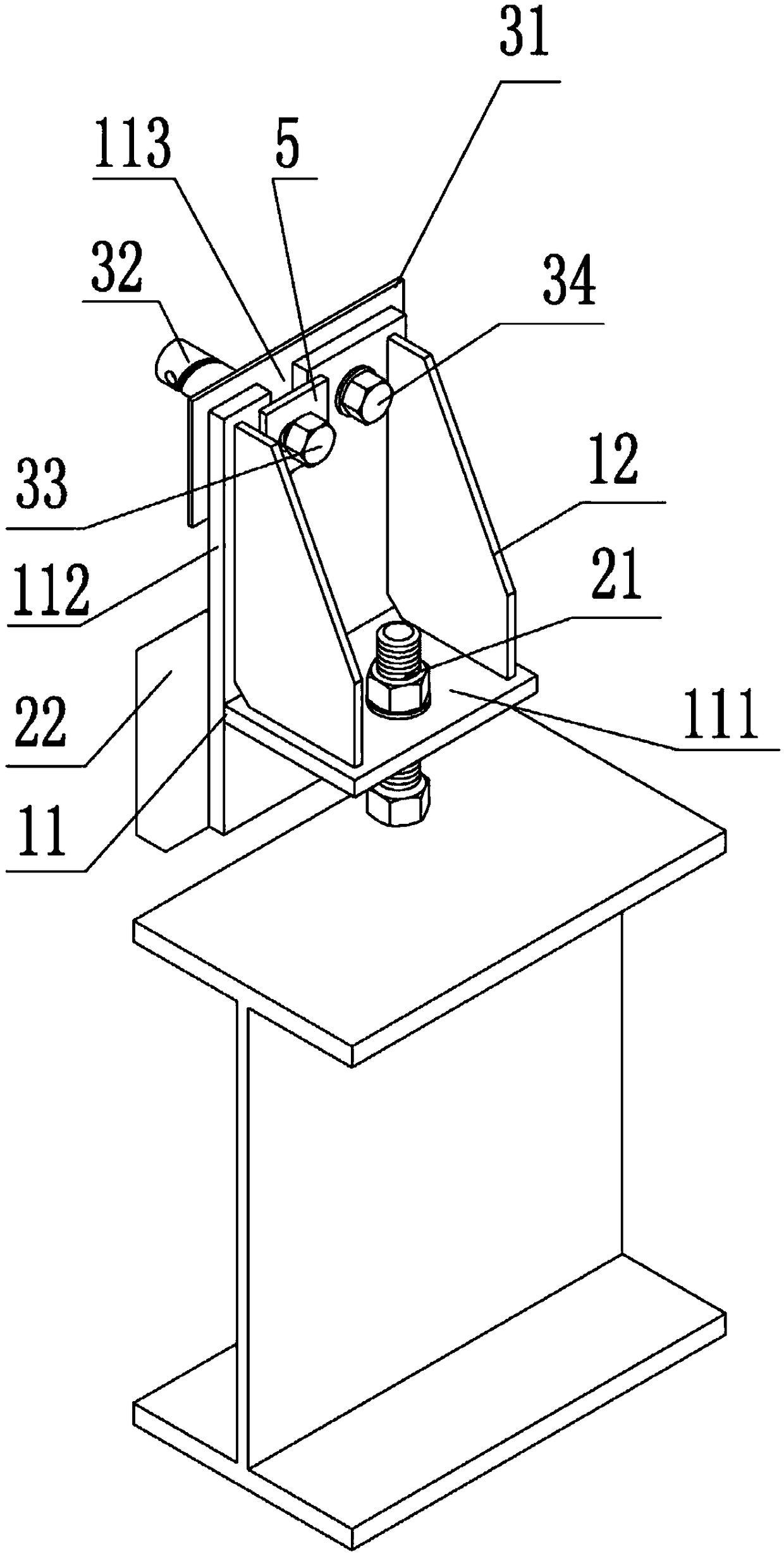

[0029] Please refer to the attached figure 1 to attach Figure 4 As shown, it is an embodiment 1 of a connection node between an upper load-bearing precast concrete exterior wall and a steel beam of the present invention, which is composed of a precast concrete exterior wall 100 , a steel beam 200 and a connection base 1 .

[0030] Wherein, the prefabricated concrete exterior wall 100 adopts single-layer wallboard or double-layer wallboard sandwiching thermal insulation cotton. The steel beam 200 is an I-shaped steel beam, a square tube beam or a box beam.

[0031] The connection base 1 connects the prefabricated concrete exterior wall 100 and the steel beam 200 , which includes a T-shaped plate 11 and a reinforcing rib 12 . The T-shaped plate 11 includes a horizontal portion 111 and a vertical portion 112 . The horizontal part 111 is connected to the upper flange of the steel beam 200 through the load-bearing anchor bolt 21, and the load-bearing anchor bolt 21 has a certai...

Embodiment 2

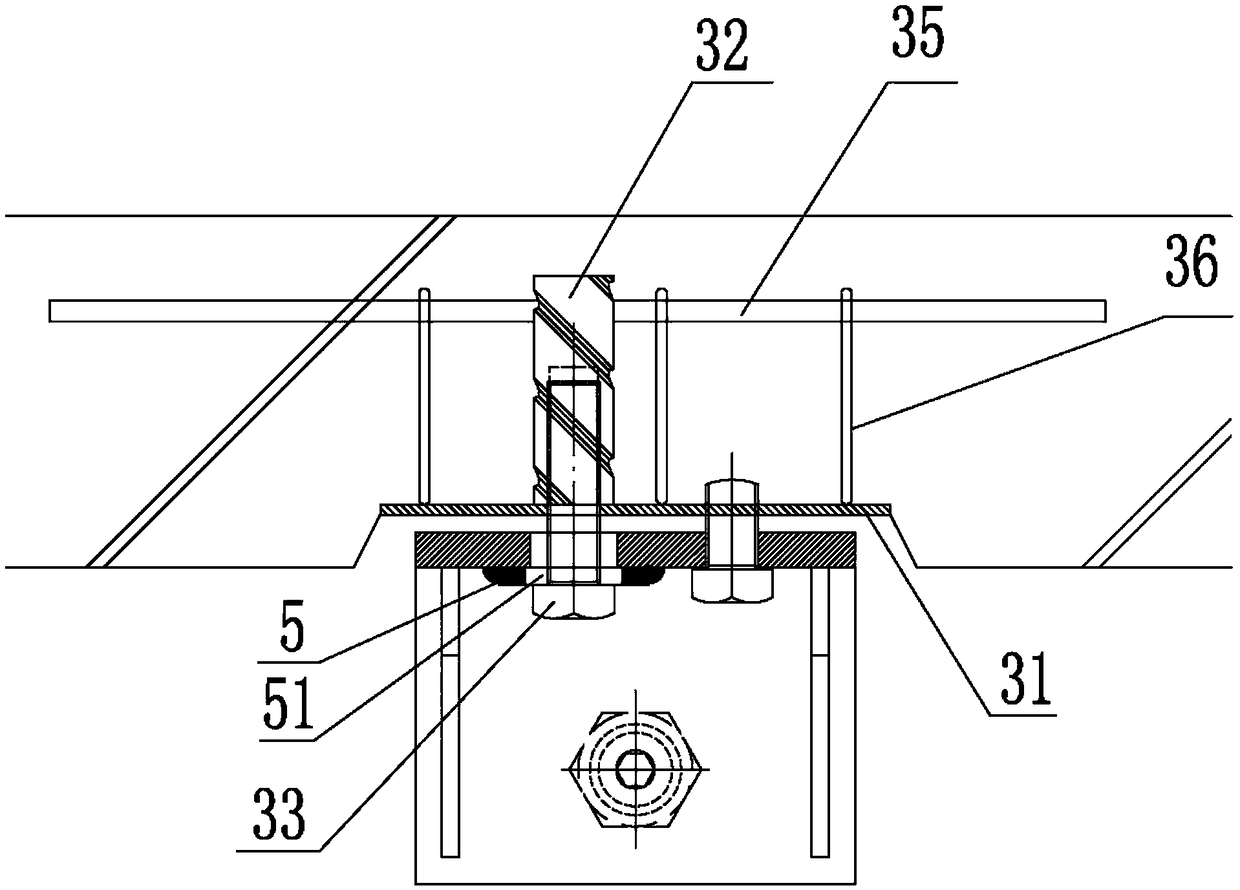

[0035] Please refer to the attached Figure 5 to attach Figure 8 As shown, it is the second embodiment of the connection node between the upper load-bearing precast concrete outer wall and the steel beam of the present invention. The difference between it and the first embodiment is that the horizontal part 111 is screwed with a load-bearing anchor bolt 21, The load-bearing anchor bolt 21 passes through a connecting channel 22 and abuts against the upper flange of the steel beam 200, and the connecting channel 22 is welded to the upper flange of the steel beam 200, thereby forming a rotatable support The seat has a certain horizontal and vertical displacement capacity, which prevents the wall from participating in the overall calculation of the structure. The similarities between the second embodiment and the first embodiment will not be repeated.

[0036] The connection nodes of the upper load-bearing prefabricated concrete outer wall and the steel beam of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com