Light steel-concrete combination structure shear wall and manufacturing method thereof

A technology of light steel structure and combined structure, which is applied in building structures, walls, building components, etc., can solve the problems of inability to meet production requirements, weak functions and forces, and high requirements for transportation and transportation of machinery and equipment, so as to improve labor productivity. , Small quality, the effect of avoiding surface cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

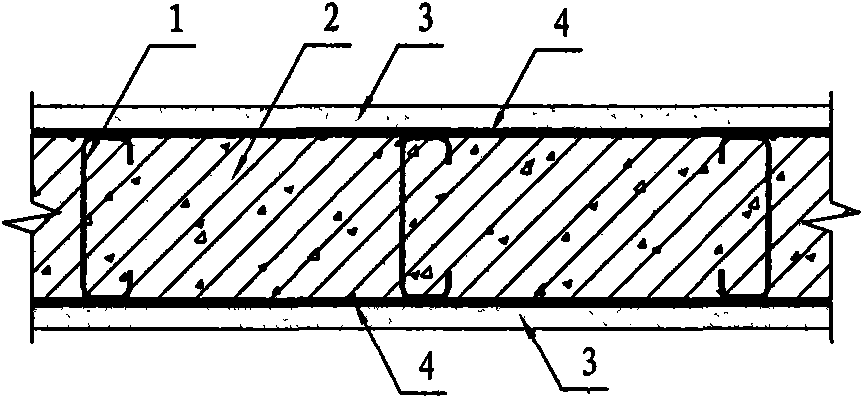

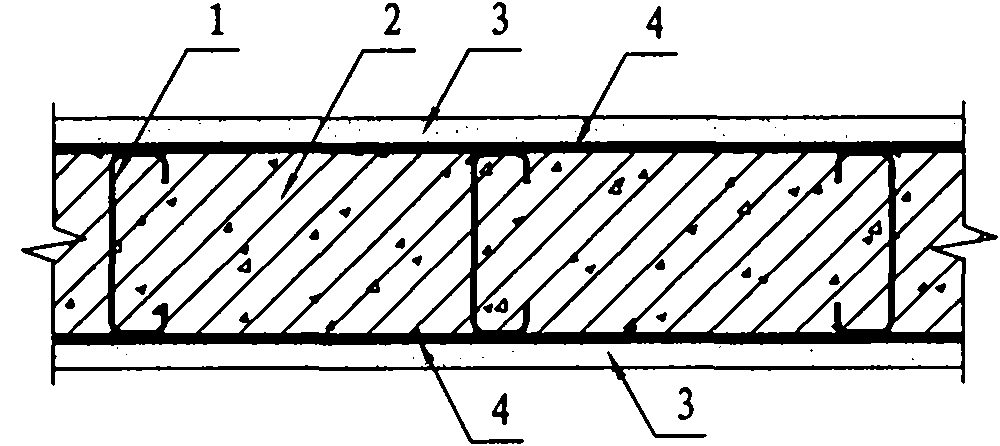

[0021] The light steel-concrete composite structure shear wall of the present invention comprises cold-formed thin-walled steel or steel trusses 1 , concrete 2 , cement boards 3 and steel bars 4 .

[0022] Such as figure 1 As shown, in the light steel-concrete composite structure shear wall of the present invention, two or more cold-formed thin-walled steel or steel trusses 1 are fixed by connectors to form a light steel structure skeleton, and steel bars 4 are fixed on both sides of the light steel structure skeleton. And the cement board 3, the concrete 2 is filled in the gap formed by the light steel structure skeleton and the cement board 3. The connecting piece for fixing the cold-formed thin-walled section steel or the steel truss 1 may be a steel strip, an angle steel or a channel steel and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com