Large-template drawing steel stranded wire

A technology of steel strands and large formwork, applied in the field of large formwork pair tensile load-bearing system, can solve the problems of affecting the appearance quality of concrete surface, the workload of filling is large, and the diameter of bolts is large. Die early, reduce the effect on the hole diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

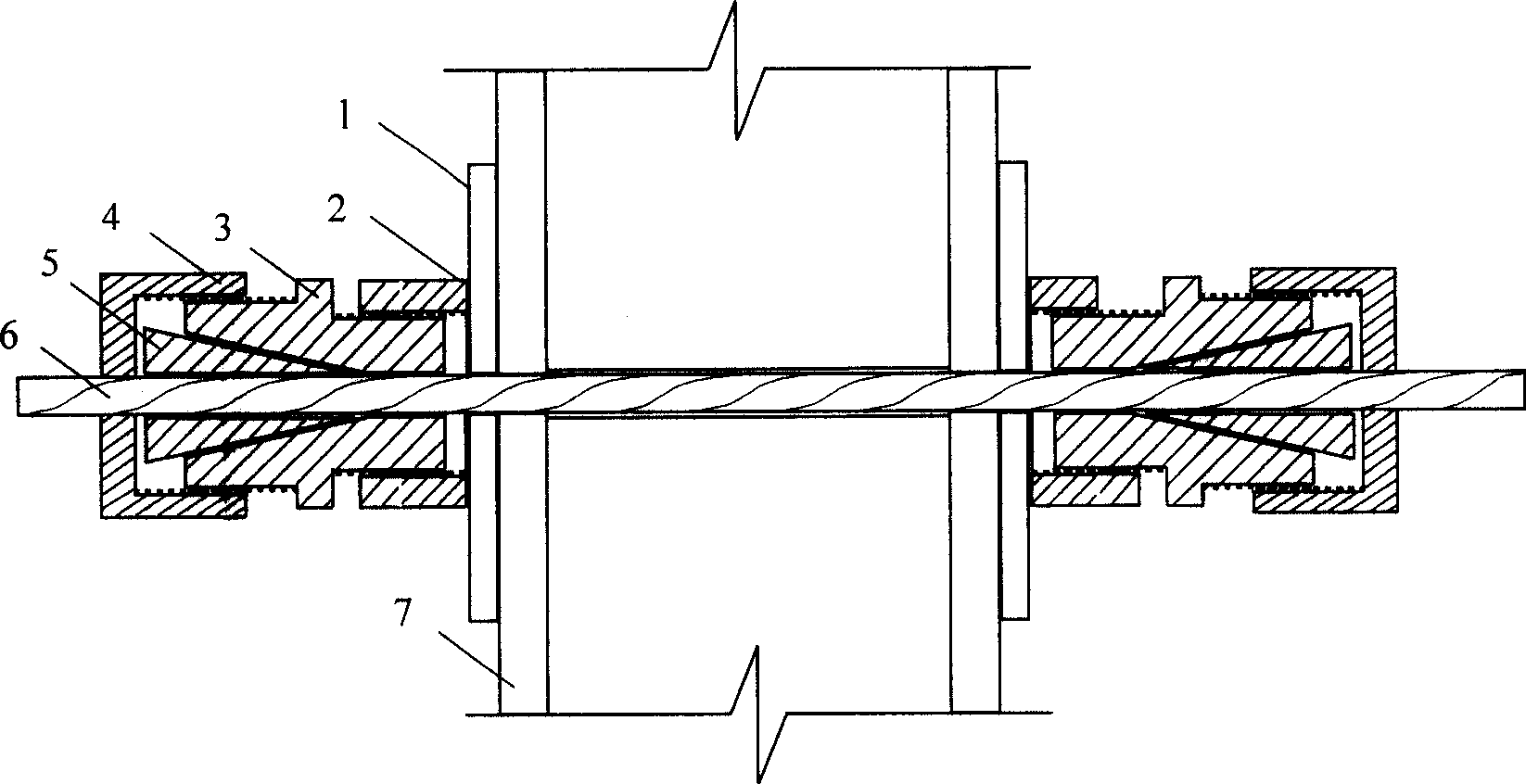

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

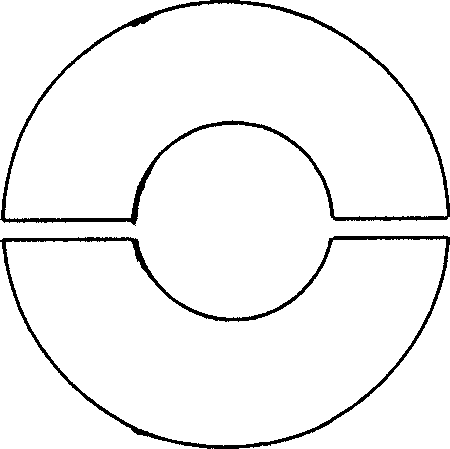

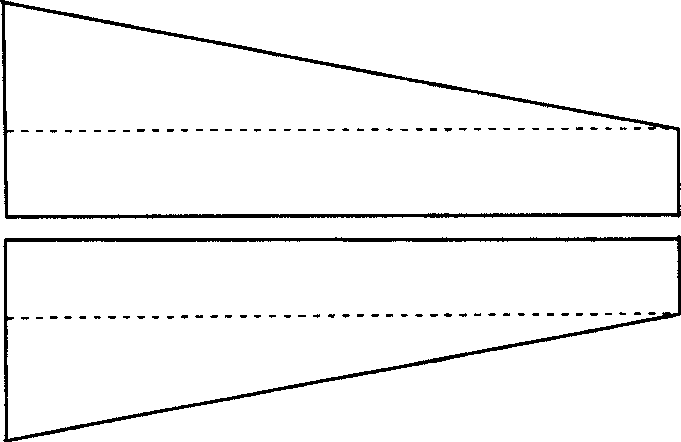

[0013] Depend on figure 1 and Figure 4 It can be seen that, firstly, lubricating oil 9 is applied to the surface of the steel strand 8, and then the sheath 10 is put on, and then one end thereof is inserted into the backing plate 1, the tensioning sleeve 2, the anchor tube 3, the clip 5, and the extrusion sleeve 4 in sequence. , tighten the anchor tube 3 and the extruding sleeve 4, make the clip 5 clamp the tensioned steel strand 6, and pass the other end into the tensioned hole of the template 7, repeat the above procedure, and place the tensioned steel strand 6 in another After the anchoring system at one end is installed, the tensioning sleeve 2 is twisted to tighten the tensioned steel strands to withstand the lateral pressure on the formwork system when pouring concrete. When the formwork is removed, the anchor system is first loosened and unscrewed, and then t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com