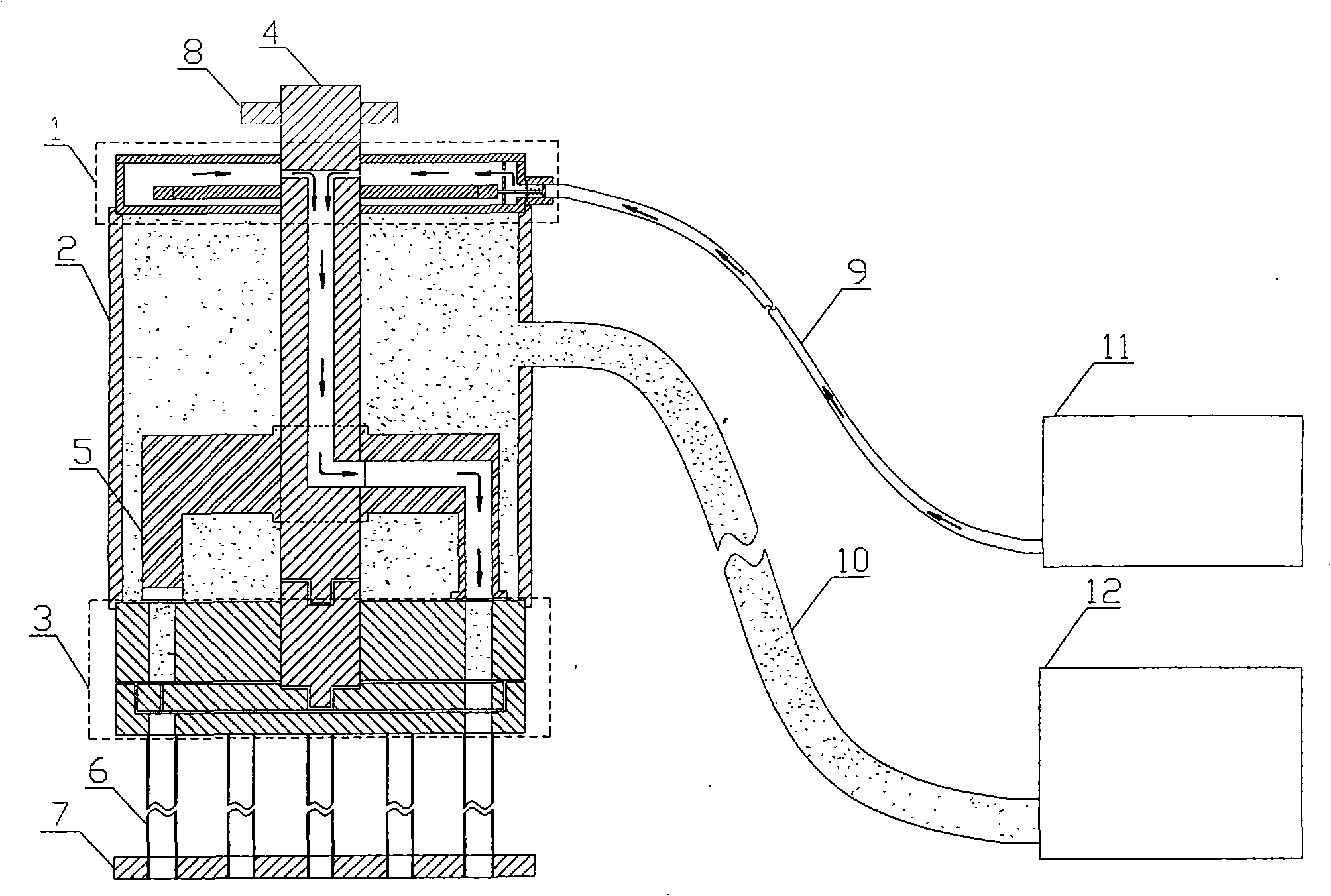

Automatic mortar spraying device for coating mortar for wall surface

A spraying device and mortar technology, which is applied in the direction of construction and building construction, can solve the problems of failure to realize automation, failure to meet energy saving requirements, and large amount of ash falling, so as to achieve fully automatic operation and controllable and adjustable mortar thickness , good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

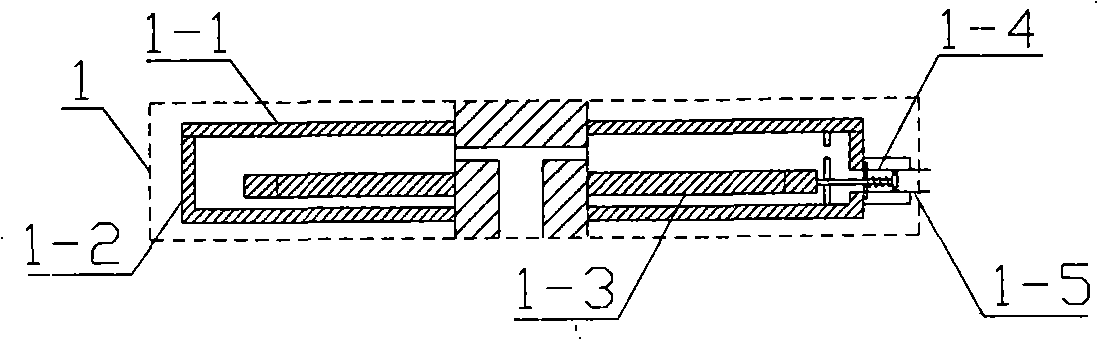

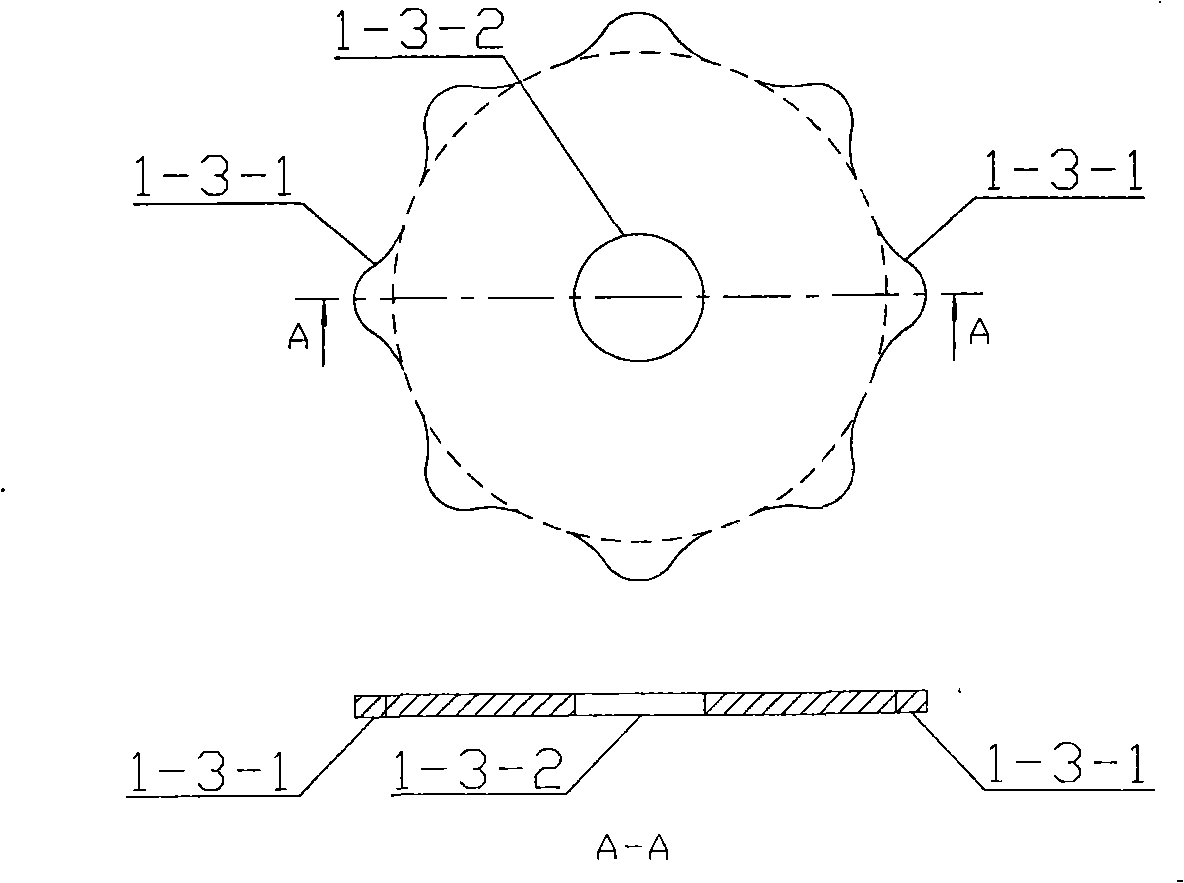

Embodiment Construction

[0076] In actual manufacturing, the components of the high-pressure air chamber 1, the mortar box 2 and the slurry-distributing tray assembly 3 are all cast by foundry, and may also be made of steel pipes or steel plates. Central rotating shaft 4 adopts round steel to make. The joints between the central rotating shaft 4 and the high-pressure air chamber 1, the mortar box 2, and the porous slurry separator 3-1 are fixed by bearings, and the joints are sealed by sealing rings. Air inlets 1-5 and pulp inlets 2-2 are connected to conveying pipes with universal quick connectors in the industry for easy installation and disassembly. Intake check valve 1-4 can adopt mechanical valve, also can adopt electromagnetic valve, triggers its switch by multi-point distributing cam 1-3. The number of the edge protrusions 1-3-1 of the multi-point gas distribution cam 1-3 is the same as the number of the grout holes 3-1-1 and the mortar injection pipes 6, and the distribution on the disk surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com