Mechanical spray plastering method and device

A technology of mechanical spraying and spraying machine, applied in the direction of construction and building structure, can solve the problems of inability to guarantee the compactness of the plastering layer, increase the maintenance workload, and the quality of the wall surface varies greatly, so as to achieve good construction quality and reduce Manual input and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

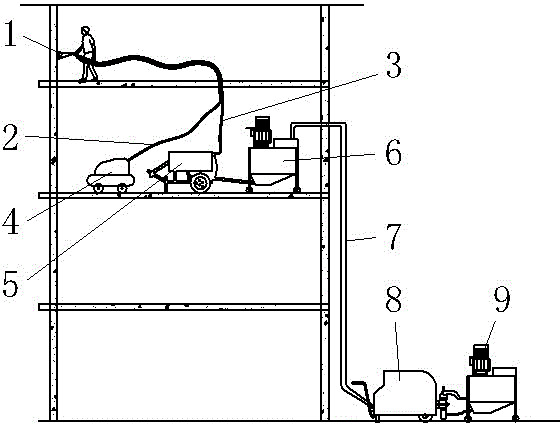

[0017] Embodiments of the present invention: when implementing a kind of mechanical spray plastering method of the present invention, can utilize existing engineering mechanical equipment to carry out, this method comprises adopting existing agitator to make the mortar that is used for brushing wall surface, its The ingredients and production process of the mortar completely adopt the mortar production method in the prior art, and the mortar in the mixer is output to the commonly used spray gun through the traditional mortar pump, and when the mortar in the mixer is output to the spray gun through the mortar pump, the The outlet end of the mortar pump is connected to a suction machine commonly used in engineering through a pipeline, and a conventional sprayer is connected to the outlet of the suction mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com