Fast mortar construction device

A construction device and mortar technology, applied in the direction of construction and building structure, can solve the problems of inability to complete the construction of the top surface, inclined surface and arc surface, different dry humidity of base surface mortar, strict requirements on mortar consistency, etc. Engineering quality analysis and continuous improvement, improving overall reliability, and the effect of flexible and fast spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

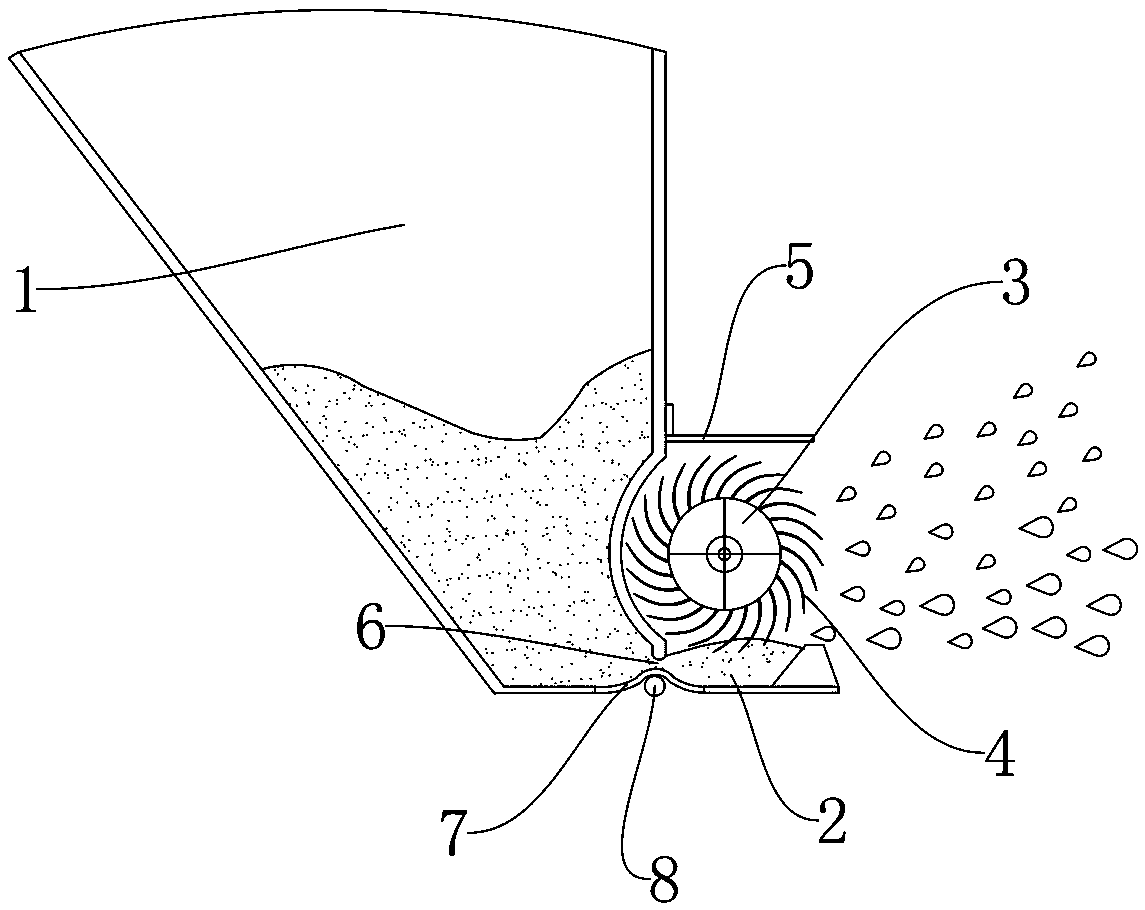

[0030] Such as figure 1 As shown, this embodiment is a rapid construction device for mortar, which has a silo and a slurry tank. The slurry tank is rectangular. It is located on the same level as the bottom plate of the silo, and the pulp discharge control valve is connected between the silo and the slurry tank. In this example, a pulp rejection mechanism is provided above the pulp tank, and a pulp baffle is arranged above the pulp rejection mechanism. One side of the pulp baffle is connected to the silo, and the other side of the pulp baffle is connected to the side far away from the silo of the pulp tank below. Form a slurry outlet.

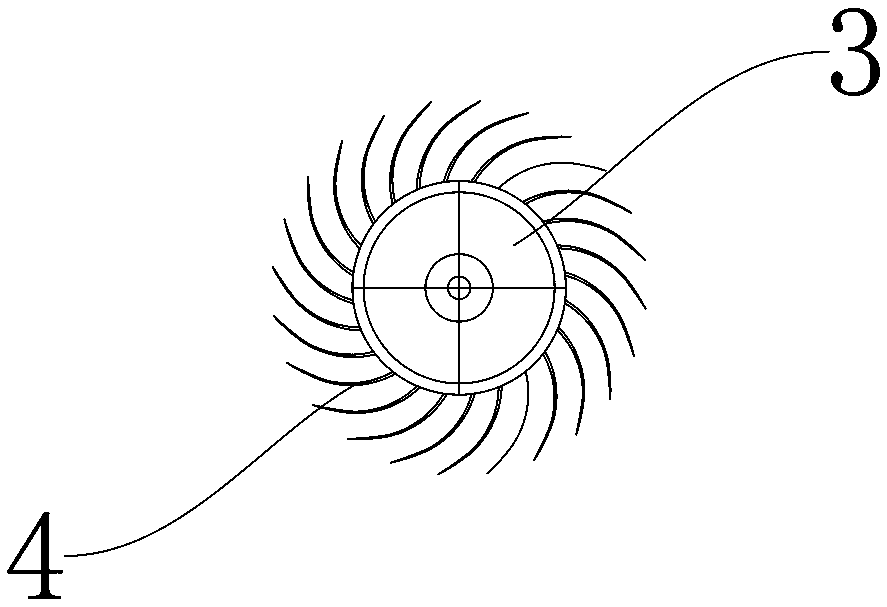

[0031] In this embodiment, the pulp rejection mechanism has a pulp rejection drum arranged horizontally and parallel to the length direction of the pulp tank, and a number of uniformly distributed pulp rejection rods are fixed on the wall of the pulp rejection drum. Such as figure 2 As shown, one end of the throwing rod is fixed to the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com