Full tail mortar quick concentrating technique in vertical sand cabin

A vertical sand bin and full tailings technology, which is applied in the field of mining, can solve the problems of low production efficiency, hardening of the bottom of the bin, and small processing capacity of full tailings, and achieve the effect of large production capacity and continuous pulping

Inactive Publication Date: 2006-01-11

CENT SOUTH UNIV

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The concentration and dehydration process requires large investment, high energy consumption, frequent filter cloth replacement, complex process, small tailings treatment capacity, and high concentration cost

[0003] At present, the vertical sand bin is mainly used for graded tailings filling, that is, the coarse tailings mortar after the whole tailings mortar of the dressing plant has been graded to remove -37μm is injected into the vertical sand bin for underground filling, because the whole tailings mortar is used in the vertical sand The natural

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

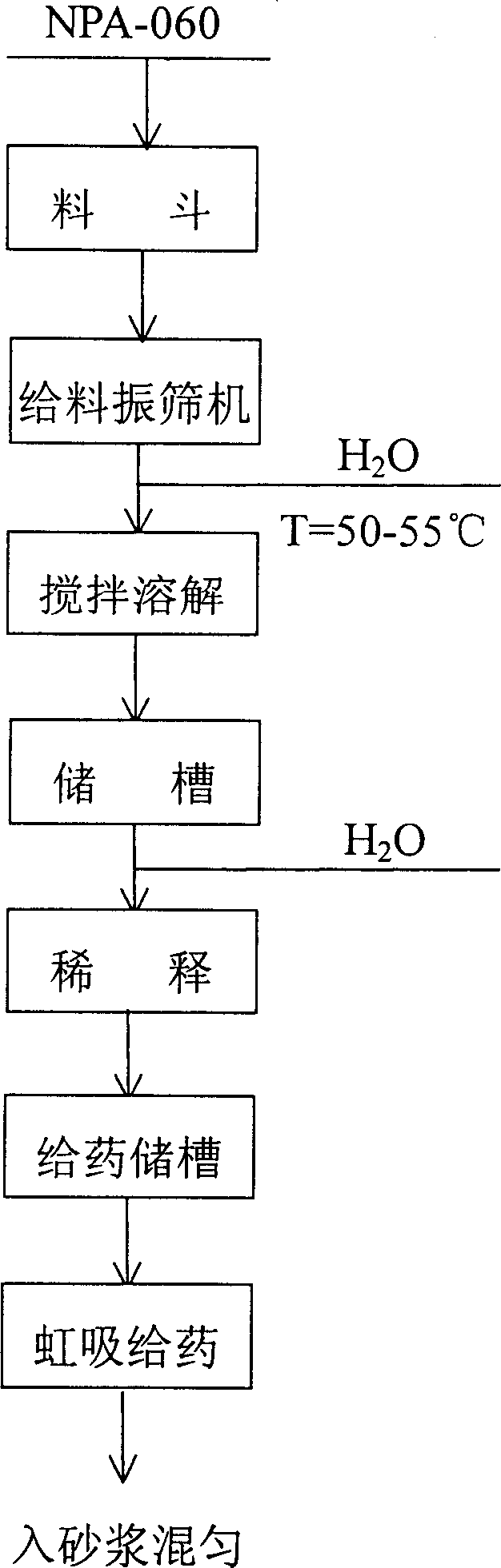

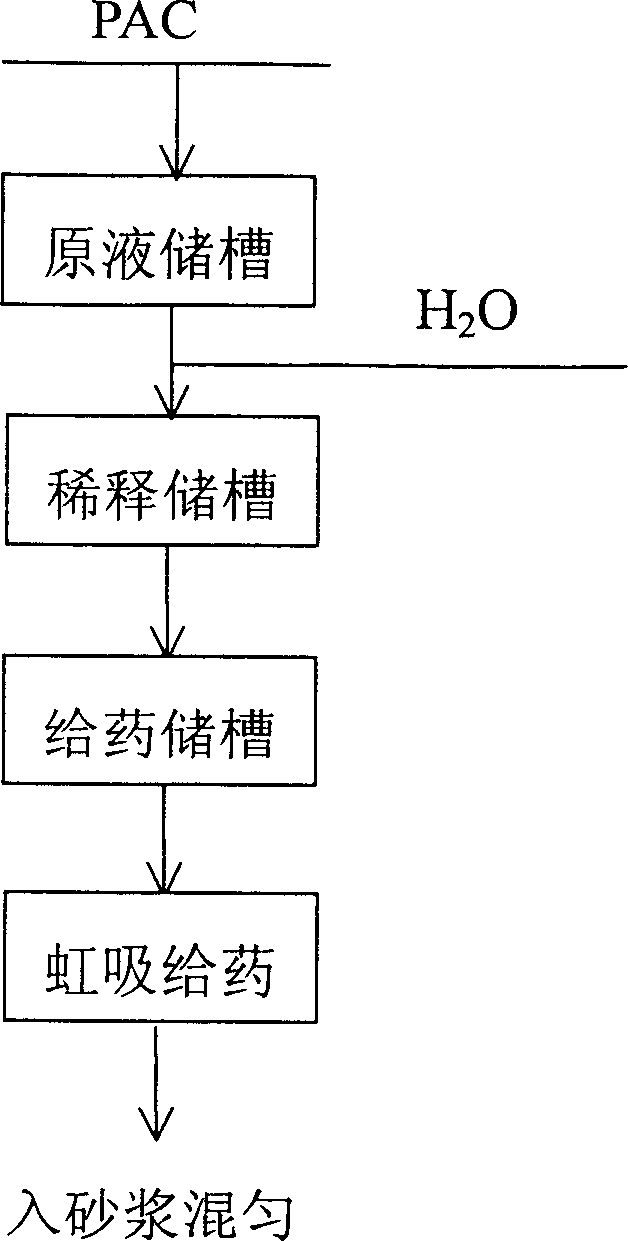

A fast concentrating technology of whole tailings in vertical tailing bunker for mine filling includes such steps as preparing efficient flocculant NPA-060 and coagulating aid PAC or BAC, proportionally adding NPA-060 to the whole tailings discharged by dressing plant, and proportionally adding PAC or BAC when the characteristics of tailings slurry begins to change.

Description

Technical field: [0001] The invention relates to the field of mine mining, in particular to a rapid concentration process for full tailings when a vertical sand bin is used for mine filling. Background technique: [0002] A key technology of the fill mining method is to use the filling material to deal with the empty area. Due to the advantages of high recovery rate and safe operation, it is widely used in underground mines. At present, when the full tailings of the concentrator are used for mine filling, they must first be dehydrated and concentrated to increase the quality concentration. That is, it is concentrated and dehydrated through a vacuum belt filter or other mechanical dehydration methods, and the moisture content of the dehydrated filter cake is about 20-22%. The concentration and dehydration process requires large investment, high energy consumption, frequent filter cloth replacement, complex process, small tailings processing capacity, and high concentration ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B03D3/06

Inventor 陈昌民王新民厉彦平张钦礼李耀武彭云琪李绍元郭昌槐

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com