A railway auxiliary vacuum automatic grouting machine

An all-in-one, automatic technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of unrealized automatic control, impact on construction quality, and large impact of manual intervention, so as to improve the degree of automatic operation and control, and ensure the weighing The effect of measuring accuracy and weighing accuracy is not reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

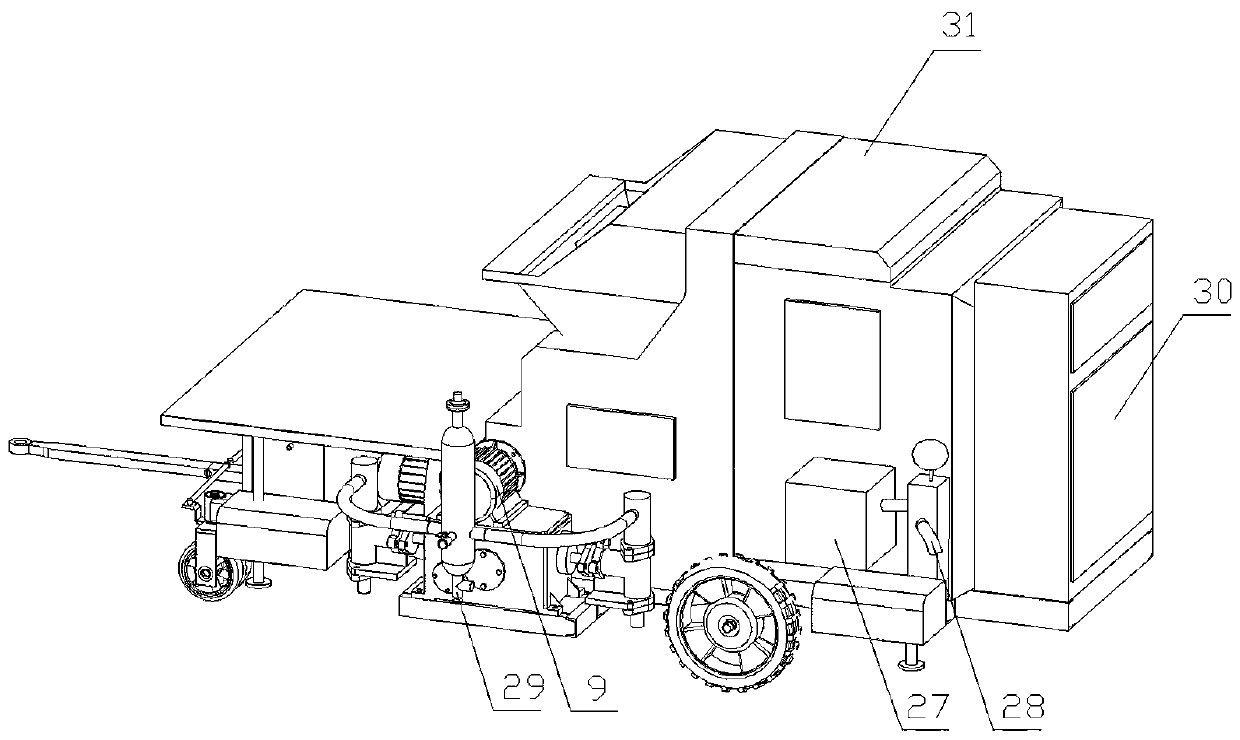

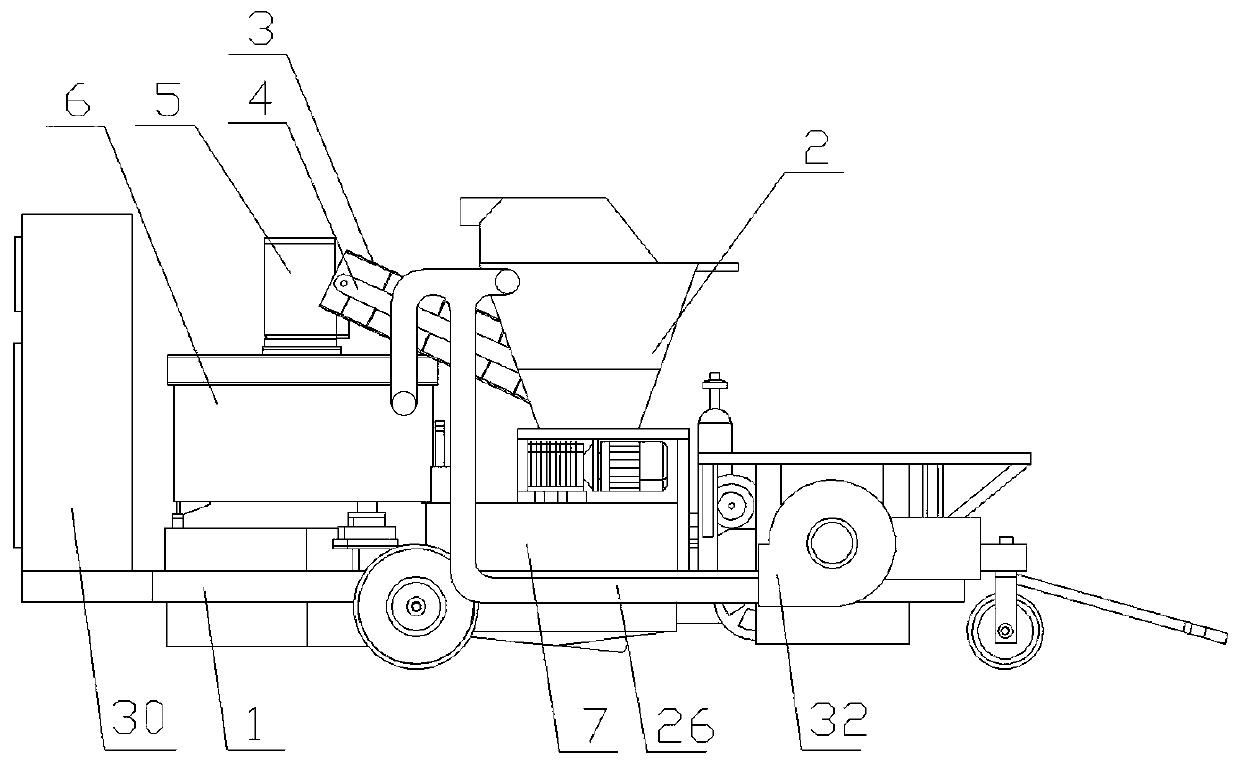

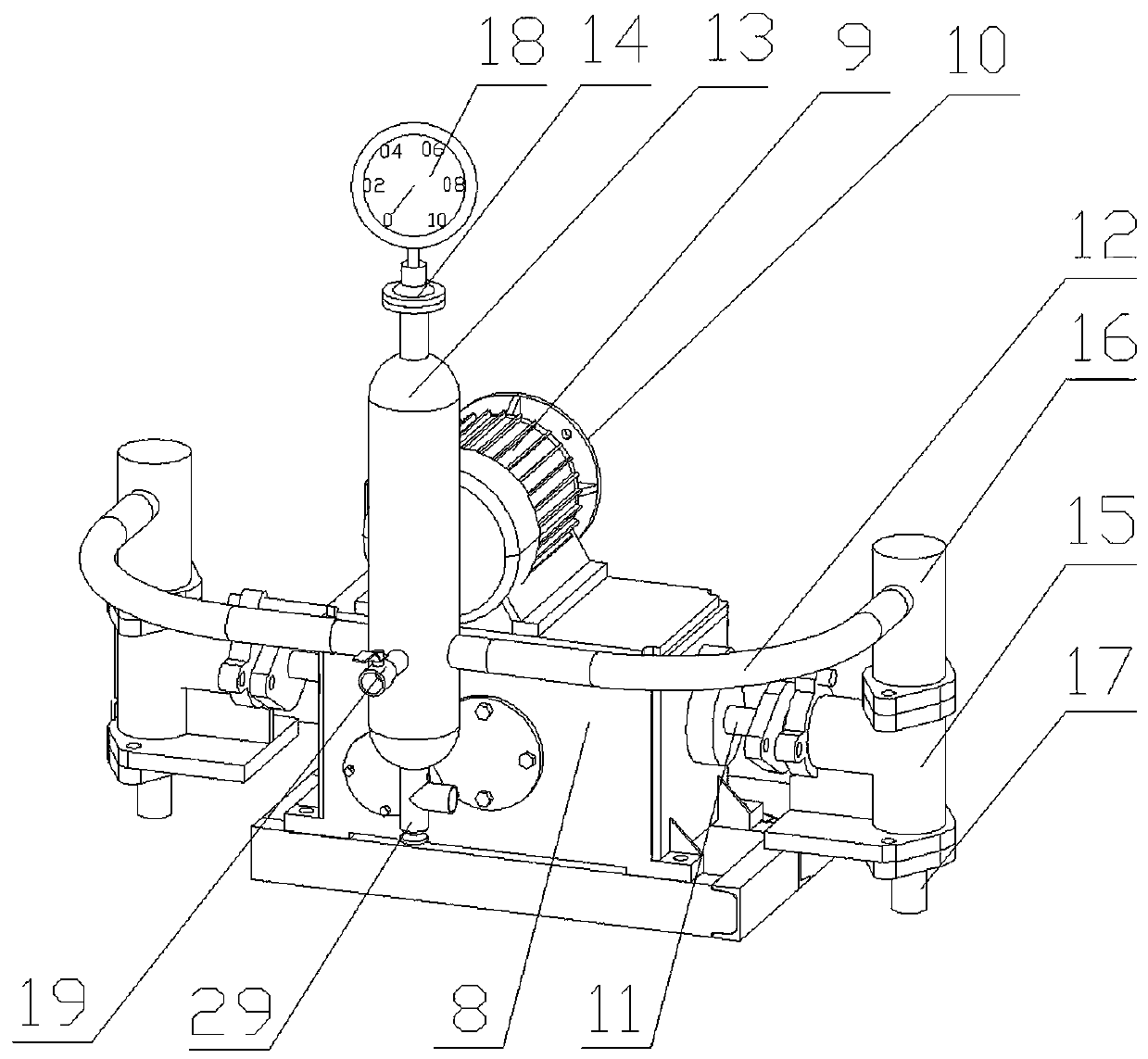

Embodiment 1

[0044] Such as Figure 6 As shown, the grouting end of the pipeline of the prestressed concrete beam is also provided with an air release pipe 33 . The slurry outlet end of the pipeline of the prestressed concrete beam is provided with a slurry outlet pipe 34 . The vacuum pipe 28, the air release pipe 33, and the grout outlet 29 are all sealed and connected to the pipes of the prestressed concrete beam, and the pipes are respectively provided with corresponding valves. The vacuuming and grouting process of embodiment one are as follows: check the valve situation of the pipeline of the prestressed concrete beam, ensure that the grouting outlet 29, the vacuum pipe 28, the air release pipe 33, and the grouting pipe 34 are all tightly connected with the pipeline, Form a sealed state, and the initial state of each valve is closed; open the valve of the vacuum tube 28 and start the vacuum pump 27 through the PLC assembly electric control box 30, and vacuumize the pipeline. When the...

Embodiment 2

[0046] Such as Figure 7 As shown, the slurry outlet end of the pipeline of the prestressed concrete beam is provided with a slurry outlet pipe 34 . The vacuum pipe 28 and the grout outlet 29 are both sealed and connected to the pipes of the prestressed concrete beams, and the pipes are respectively provided with corresponding valves. The vacuuming and grouting process of embodiment two are as follows: check the valve situation of the pipeline of the prestressed concrete beam, ensure that the grouting outlet 29, the vacuum pipe 28, the air release pipe 33, and the grouting pipe 34 are all tightly connected with the pipeline, Form a sealed state, and the initial state of each valve is closed; open the valve of the vacuum tube 28 and start the vacuum pump 27 through the PLC assembly electric control box 30, and vacuumize the pipeline. When the vacuum in the pipeline is stable at the standard technical requirements When within the range, close the valve of the vacuum tube 28, di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com