Weak cyclone slurry making method for graded tailings filling type vertical sand silo

A vertical sand bin and slurry-making technology, which is applied in the fields of filling, earthwork drilling, sustainable waste treatment, etc., can solve the problems of unstable slurry-making process, affecting the effect, and short service life, so as to save electricity and water Consumption, reduce the amount of cement, reduce the effect of infrastructure investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

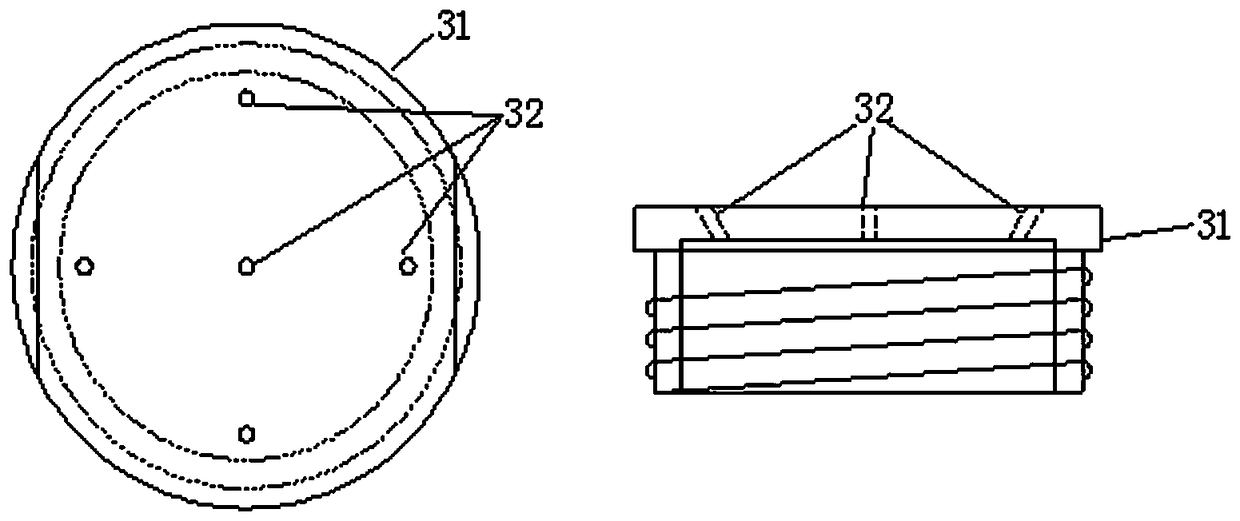

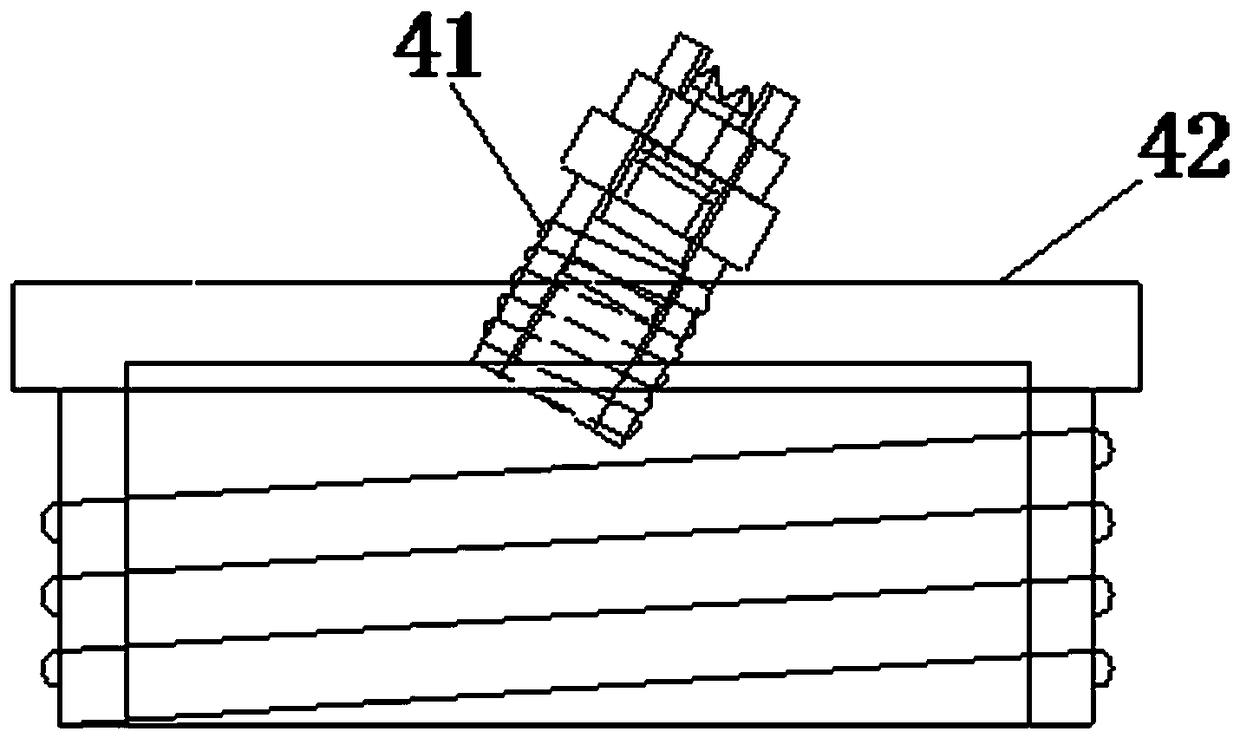

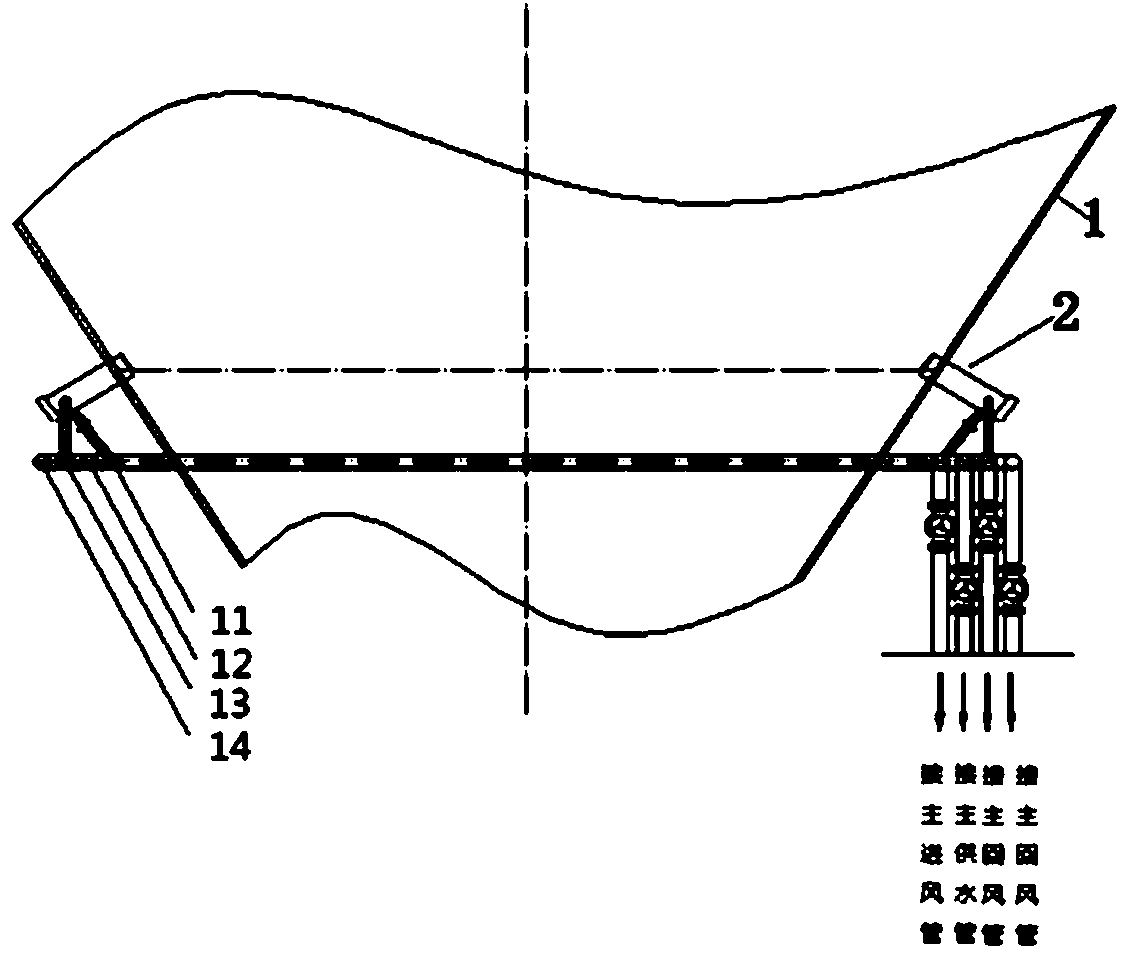

[0037] see Figures 1 to 4 Shown, a kind of classification tailings filling vertical sand bin weak swirling slurry making method, described slurry comprises the following steps:

[0038] (1) After the tailings of the dressing plant pass through the cyclone group, the graded tailings are formed, and the effective height of the grit chamber is determined to be ≥ 10m. The diameter of the grit chamber of the cyclone is 20, and the concentration is about 35%. The tailing sand settles behind the sand bin, and its concentration is 85% at the bottom of the sand bin. During the filling process, the high-concentration tailing sand at the bottom of the sand bin is used for local weak slurrying to increase the preparation concentration of the mortar and avoid damage to the entire sand bin. Perform strong pulping; at the same time, the tailings are continuously supplied and settled, which can supplement the tailings of the sand bin. The concentration of tailings at the bottom of the sand b...

Embodiment 2

[0047] see Figures 1 to 4 Shown, a kind of classification tailings filling vertical sand bin weak swirling slurry making method, described slurry comprises the following steps:

[0048] (1) The tailings of the dressing plant will form graded tailings after passing through the cyclone group, and it is determined that the effective height of the grit chamber is ≥ 10m. The diameter of the cyclone grit nozzle is 25, and the concentration is about 40%. The tailing sand settles behind the sand bin, and its concentration is 90% at the bottom of the sand bin. During the filling process, local weak slurrying of high-concentration tailings at the bottom of the sand bin is used to increase the preparation concentration of the mortar and avoid damage to the entire sand bin. Perform strong pulping; at the same time, the tailings are continuously supplied and settled, which can supplement the tailings of the sand bin. The concentration of tailings at the bottom of the sand bin is kept abov...

Embodiment 3

[0057] see Figures 1 to 4 Shown, a kind of classification tailings filling vertical sand bin weak swirling slurry making method, described slurry comprises the following steps:

[0058] (1) After the tailings of the dressing plant pass through the cyclone group, the graded tailings are formed, and the effective height of the grit chamber is determined to be ≥ 10m. The diameter of the grit chamber of the cyclone is 28, and the concentration is about 38%. The tailing sand settles behind the sand bin, and its concentration is 88% at the bottom of the sand bin. During the filling process, local weak slurrying of high-concentration tailings at the bottom of the sand bin is used to increase the preparation concentration of the mortar and avoid damage to the entire sand bin. Perform strong pulping; at the same time, the tailings are continuously supplied and settled, which can supplement the tailings of the sand bin. The concentration of tailings at the bottom of the sand bin is kep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com