Composite polymerization inhibitor for extracting and rectifying conjugated diene with dimethylformamide and use method

A technology of dimethylformamide and conjugated diene, which is applied in the field of composite polymerization inhibitor for N,N-dimethylformamide extractive and rectified conjugated diene, can solve the problem that the content of sodium nitrite cannot be effectively Control, polymerization inhibition effect cannot be guaranteed, liquid flooding and processing capacity decline, etc., to achieve good polymerization inhibition effect, facilitate accurate quantitative delivery, and improve solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 3

[0027] Preparation method of component A and component B:

[0028] Prepare Part A and Part B separately.

[0029] Component A of a mixed solution obtained by dissolving 4-Hydroxy-TEMPO, 2-hydroxyethylamine and auxiliary agents in toluene. Place Component A in the Component A tank.

[0030] Sodium nitrite is dissolved in water to obtain component B. Place Component B in the Component B tank.

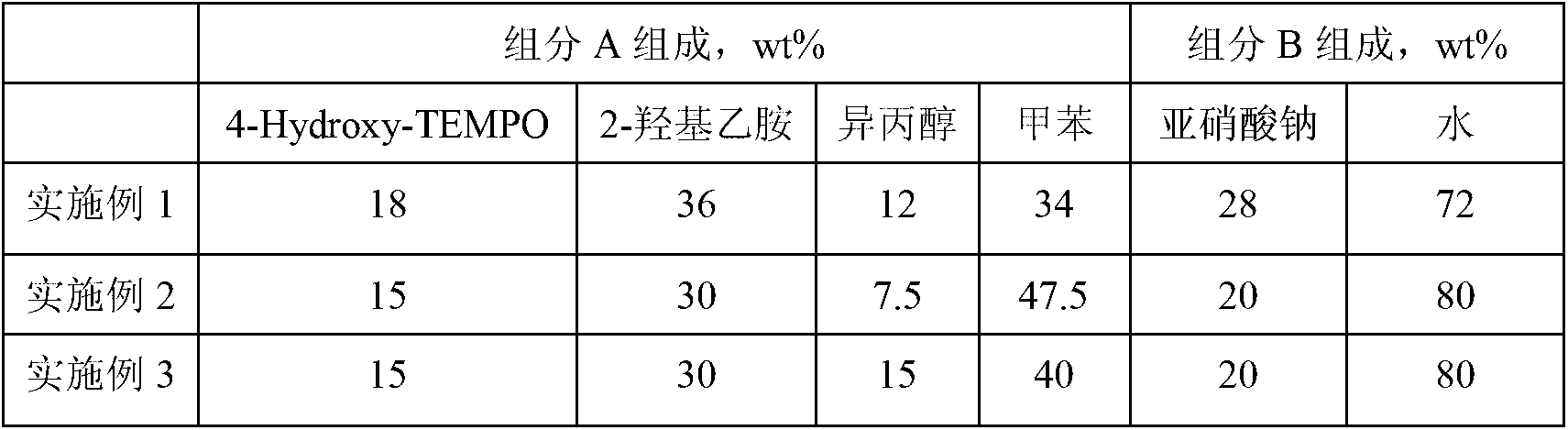

[0031] The preparation concentrations of component A and component B are shown in Table 1.

[0032] Table 1 embodiment component A, component B preparation concentration

[0033]

[0034] The above-mentioned polymerization inhibitor is applied to the dimethylformamide extractive distillation isoprene process, and this embodiment is applied to the second extractive distillation system of the C5 separation device. The second extractive distillation system is composed of a second extractive distillation tower, a desorption tower and a vacuum desorption tower. It further purifies the ...

Embodiment 1

[0059] In the initial stage of device feeding and start-up, due to the existence of corrosion, surface active centers in the equipment, and high oxygen content in dead corners, etc., a relatively high content of polymerization inhibitor is required for inhibition, and the consumption of polymerization inhibitor is also large. Therefore, polymerization inhibition The preparation concentration is high. In component A, the concentration of 4-Hydroxy-TEMPO is 18%, the concentration of 2-hydroxyethylamine is 36%, and the concentration of isopropanol is 12%. Since isopropanol has a solubilizing effect, 2-hydroxyethylamine also has a solubilizing effect effect, all 4-Hydroxy-TEMPO dissolves. The sodium nitrite content of component B is 28%, and the concentration is correspondingly higher.

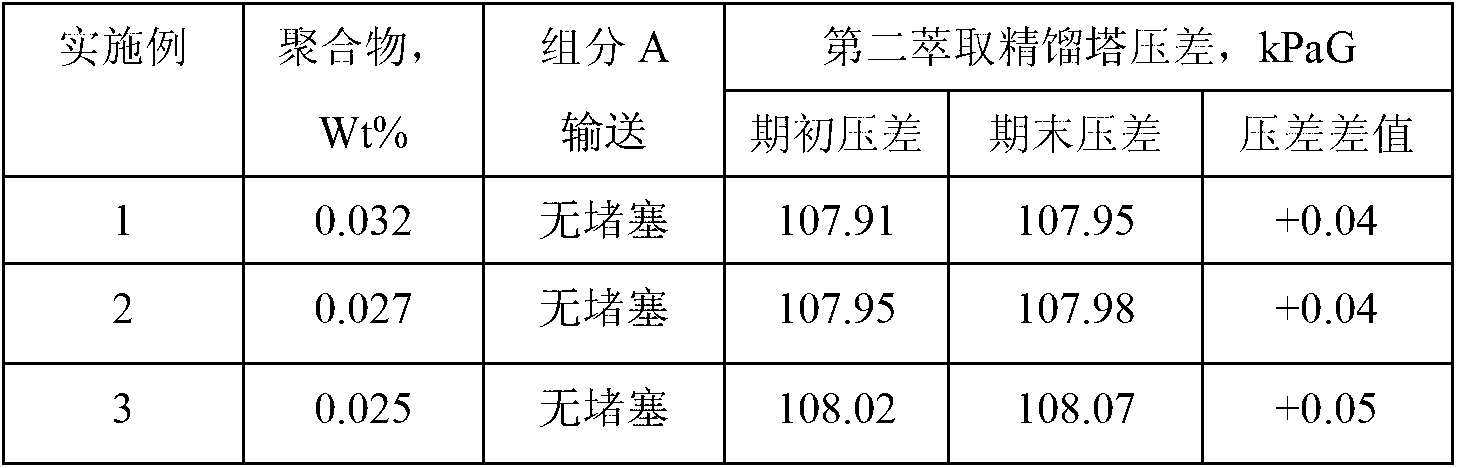

[0060] During the first 3 months of start-up, there was no clogging of component A pipeline. The average polymer content in the circulating solvent is 0.032%, which is at a relatively low level,...

Embodiment 2

[0062] In seasons when the temperature is higher than 18°C, the concentration of component A4-Hydroxy-TEMPO is 15%, and the concentration of 2-hydroxyethylamine is 30%. Since the temperature is not low, the amount of auxiliary agent isopropanol can be added a little less, and the concentration is 7.5%. . Component B sodium nitrite content is 20%.

[0063] During the 3 months of the observation period, no clogging of component A pipeline was observed. The average polymer content in the circulating solvent was measured to be 0.027%, indicating that the polymerization inhibition effect is good and the amount of polymer generated is small. The operation of the second extractive distillation column was stable, the pressure difference was stable, and the pressure difference changed little, indicating that sodium nitrite was not deposited on the solvent feed plate and downcomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com