Two-component high-penetrability epoxy resin waterproof reinforcing coating, and preparation method and application thereof

A technology of epoxy resin and reinforcing coating, which is applied in the field of material engineering, can solve the problems of high viscosity, long curing time, and lack of permeability, etc., and achieve the effect of high cost performance and excellent permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

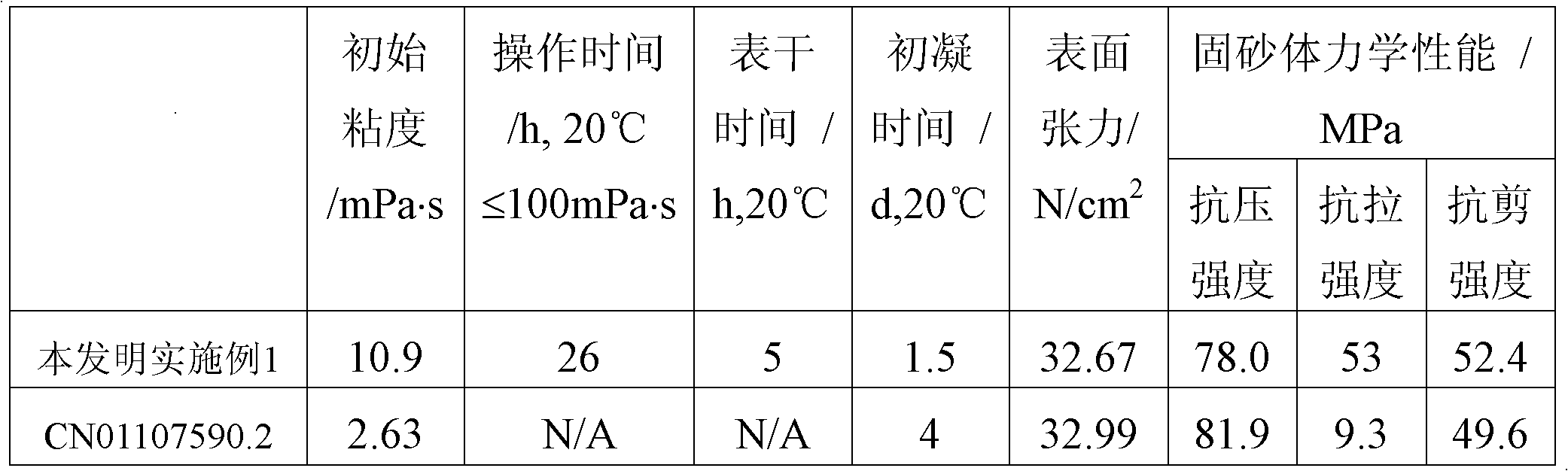

Examples

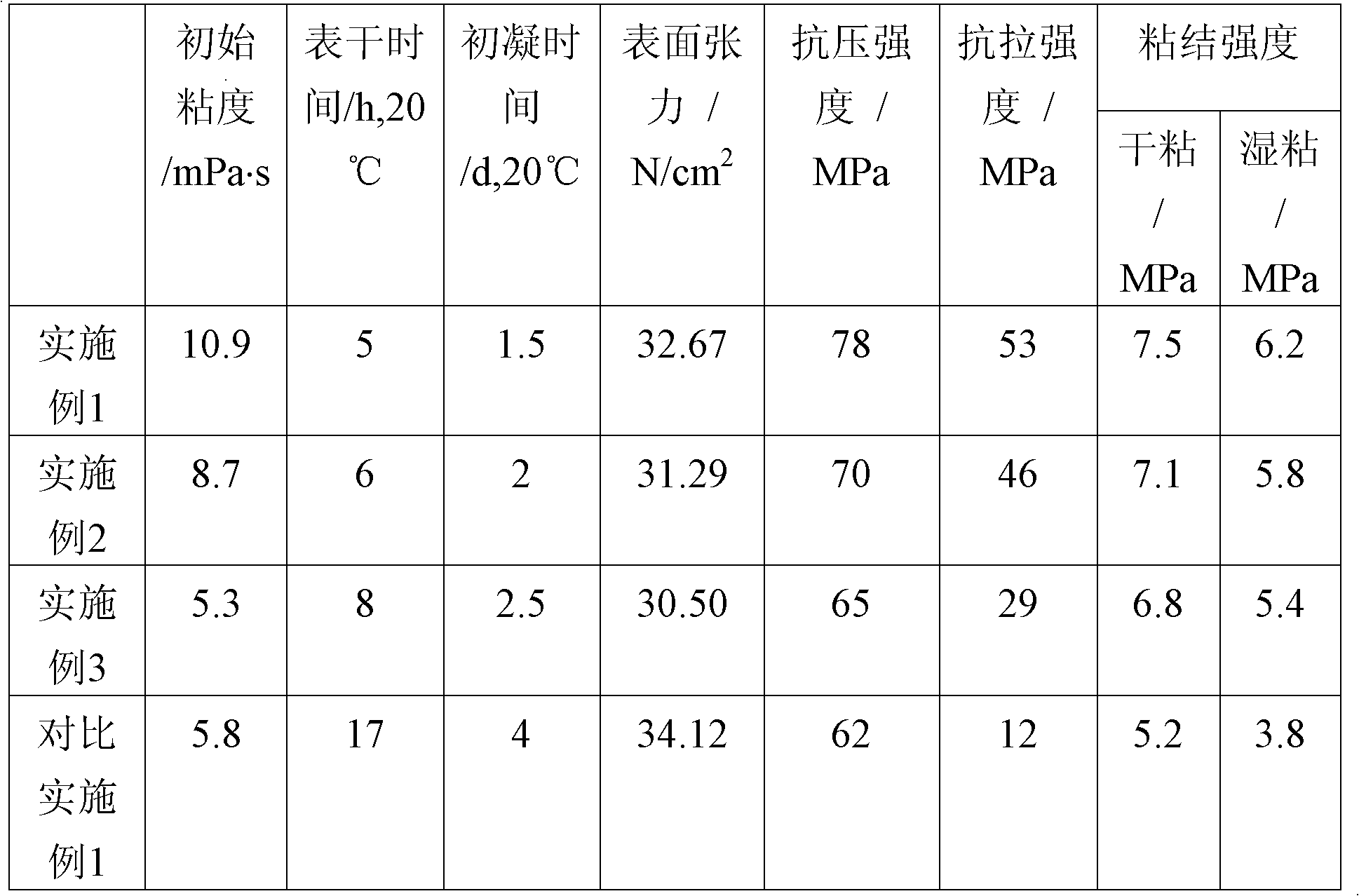

Embodiment 1

[0046] A preparation method for a two-component high-permeability epoxy resin waterproof reinforcing coating, comprising the following steps:

[0047] (1) Add 10 parts by weight of methionine and 0.5 parts by weight of ethylenediamine to 20 parts by weight of absolute ethanol, stir and mix to prepare an intermediate active agent.

[0048] (2) 50 parts by weight of E-44 bisphenol A type epoxy resin, 20 parts by weight of furfural, 20 parts by weight of acetone, 10 parts by weight of butanone, 10 parts by weight of butyl glycidyl ether, 5 parts by weight of 1,4- Add butanediol diglycidyl ether, 2 parts by weight of ethylene glycol, and 2 parts by weight of polyoxyethylene pentylphenol ether into the reactor and stir for 20 minutes to obtain the main agent A liquid after being uniform.

[0049] (3) 10 parts by weight of diethylenetriamine, 7 parts by weight of the intermediate active agent of step (1), 3 parts by weight of γ-aminopropyl triethoxysilane, 1 part by weight of N, N-d...

Embodiment 2

[0052] A preparation method for a two-component high-permeability epoxy resin waterproof reinforcing coating, comprising the following steps:

[0053] (1) Add 5 parts by weight of methionine and 2 parts by weight of hexamethylenediamine to 10 parts by weight of absolute ethanol, stir and mix to prepare the intermediate active agent.

[0054] (2) with 75 parts by weight of F-51 phenolic epoxy resin, 30 parts by weight of furfural, 40 parts by weight of cyclohexanone, 5 parts by weight of butanone, 20 parts by weight of ethylene glycol diglycidyl ether, 5 parts by weight of glycerol, Add 4 parts by weight of polyoxyethylene hexylphenol ether into the reactor and stir for 20 minutes to obtain the main agent A liquid after being uniform.

[0055] (3) 15 parts by weight of triethylenetetramine, 2 parts by weight of the intermediate active agent of step (1), 5 parts by weight of N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane , 3 parts by weight of 2,4,6-tris(dimethylamino)phen...

Embodiment 3

[0058] A preparation method for a two-component high-permeability epoxy resin waterproof reinforcing coating, comprising the following steps:

[0059] (1) In 30 parts by weight of absolute ethanol, add 20 parts by weight of methionine, 2 parts by weight of hexamethylenediamine and 2 parts by weight of butanediamine, stir and mix to prepare the intermediate active agent.

[0060] (2) 45 parts by weight of DER-354 bisphenol F type epoxy resin, 15 parts by weight of furfural, 50 parts by weight of acetone, 20 parts by weight of bianyl glycidyl ether, 10 parts of neopentyl glycol diglycidyl ether, 3 parts by weight 1 part sorbitol and 8 parts by weight of polyoxyethylene nonylphenol ether were added into the reactor and stirred for 20 minutes to obtain the main agent A liquid after being uniform.

[0061] (3) 20 parts by weight of isophorone diamine, 3 parts by weight of the intermediate active agent of step (1), 5 parts by weight of aniline triethoxysilane, and 4.5 parts by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com