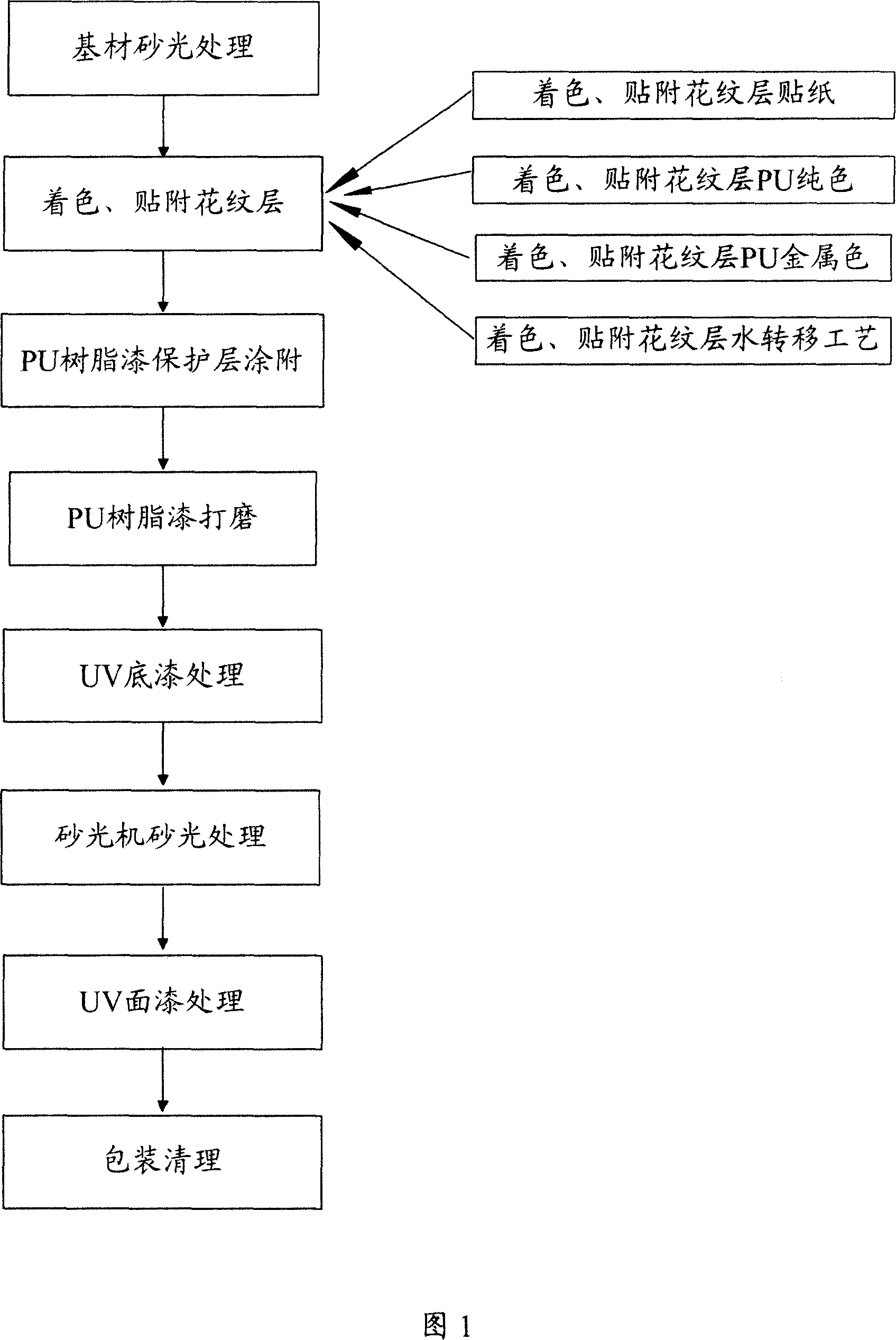

Decorative board processing method

A processing method and technology for decorative panels, which are applied in the fields of decorative panels for decoration and furniture materials, can solve the problems of lack of brightness on the surface of PVC laminated decorative panels, poor surface effect of melamine veneer, low surface hardness and no scratch resistance, etc. To achieve the effect of bright and rich colors, excellent environmental protection performance, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: UV finishing process of decorative board sticker pattern

[0036] First use a belt sander (effective sanding width greater than 1250mm) with 150#+240# two sanding units to fully sand the unattached side of the single-sided melamine decorative board, and it must be smooth and smooth . Use a gluing machine or a roller to evenly coat the sanded side with white latex, with an amount of 50g per square meter, and immediately attach the cut decorative paper to the board without wrinkles and air bubbles, and then place the pasted board Press in the adjusted hot press for 5 minutes, the temperature of the hot press is 40 degrees Celsius, and the pressure is 100 bar. After an interval of 15 hours, spray the transparent resin varnish on the paper surface, let the varnish penetrate into the paper and cure naturally. After it is fully cured, polish it thoroughly with a white cleaning cloth, and do not break the paper surface. Adjust the UV assembly line, clean the poli...

Embodiment 2

[0037] Example 2: UV finishing process of decorative board PU solid color.

[0038] a. Stick coating process to coat PU color paint;

[0039] First use a belt sander (effective sanding width greater than 1250mm) with 150#+240# two sanding units to fully sand one side of the double-sided melamine decorative board, and it must be smooth and smooth. Use a PU stick coater to divide the PU color paint into three times on the sanded side, and apply 70 grams per square meter each time evenly. After the color paint is fully surface-dried (25°C, 4 hours), apply the PU varnish again. 100 grams per square meter. go to C.

[0040] b. Spraying process to coat PU color paint;

[0041] First use a belt sander (effective sanding width greater than 1250mm) with 150#+240# two sanding units to fully sand one side of the double-sided melamine decorative board, and it must be smooth and smooth. Use a spray gun to evenly coat the PU color paint at 250 grams per square meter on the side that has...

Embodiment 3

[0043] Example 3: UV finishing process of decorative board PU metal color.

[0044] First use a belt sander (effective sanding width greater than 1250mm) with 150#+240# two sanding units to fully sand one side of the double-sided melamine decorative board, and it must be smooth and smooth. Use a spray gun to evenly coat the PU metal color paint with 450 grams per square meter on the side that has been sanded. After the metal color paint is fully surface-dried (25 ° C, 4 hours), spray another PU varnish of 100 grams per square meter. Put it aside for 12 hours until it is fully cured, and then polish it fully with 320# sandpaper, adjust the UV assembly line, clean the polished board and send it to the roller coater, and apply 10g of UV primer per square meter with the technology of showering and rolling before entering. Flow coater, spray 80g of UV primer, adjust the oil temperature and oil pump, transmission speed according to the model of the paint manufacturer, and enter the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com