Method for preparing modified chlorinated polypropylene and paint produced by modified chlorinated polypropylene for plastic-steel doors and windows

A technology of chlorinated polypropylene and chlorinated polypropylene liquid, applied in coating and other directions, can solve the problem of not meeting consumers' personalized requirements for door and window products, restricting the large-scale application of colored plastic steel doors and windows, poor weather resistance, acid and alkali resistance. Good adhesion and other problems, to achieve the effects of excellent adhesion and weather resistance, high hardness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

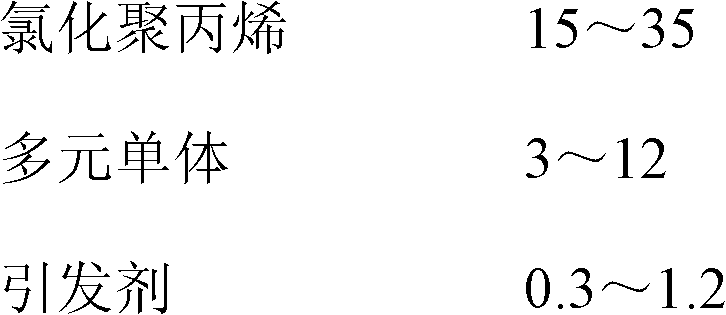

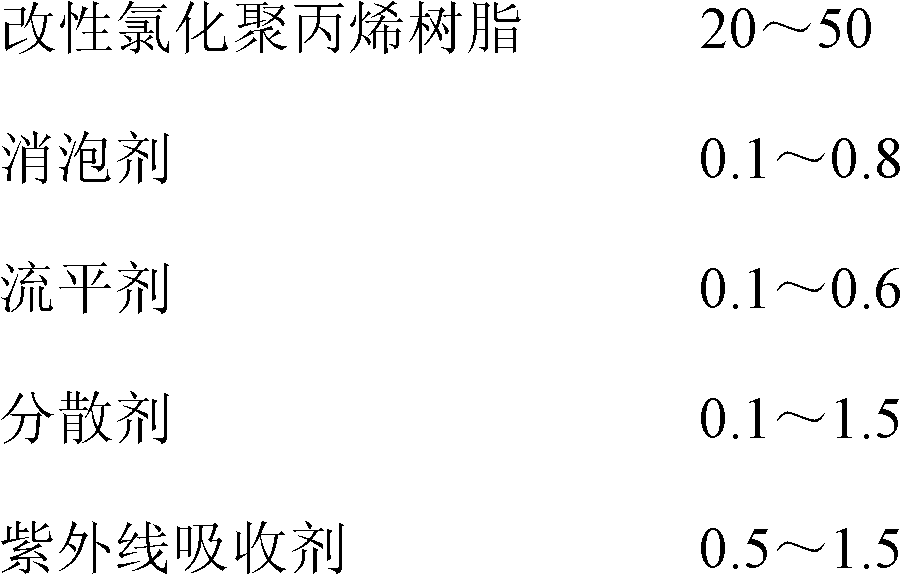

[0045] Preparation of modified chlorinated polypropylene:

[0046] a) Add 30 parts of chlorinated polypropylene with a chlorine content of 20% to 40% to 76 parts of toluene, heat up to 70-80°C to completely dissolve the material, and obtain a chlorinated polypropylene liquid;

[0047] b) Dissolving 4.0 parts of methyl methacrylate and 5.1 parts of butyl acrylate with 14 parts of toluene to obtain a mixed monomer liquid as a grafting liquid;

[0048] c) accurately weigh the initiator dibenzoyl peroxide BPO of 0.91 parts, wherein 0.23 parts of the initiator BPO weighed, dissolve with 2 parts of toluene, join in the chlorinated polypropylene solution that a process dissolves, and then Add 0.68 parts of initiator BPO to the grafting solution prepared in step b, and then add the grafting solution to the constant pressure dropping funnel for subsequent use;

[0049] d) Introduce nitrogen gas into the chlorinated polypropylene liquid containing the initiator, wait until the temperat...

Embodiment 2

[0052] Preparation of modified chlorinated polypropylene:

[0053] a) Add 29 parts of chlorinated polypropylene with a chlorine content of 20% to 40% to 73 parts of xylene, heat up to 70-80°C to completely dissolve the material, and obtain a chlorinated polypropylene liquid;

[0054] b) Dissolving 4.6 parts of ethyl methacrylate and 4.0 parts of ethyl acrylate with 12 parts of xylene to obtain a mixed monomer liquid as a grafting liquid;

[0055] c) Accurately weigh 0.86 parts of initiator azobisisobutyronitrile, dissolve 0.43 parts of initiator azobisisobutyronitrile with 4 parts of xylene, and add to the dissolved chlorinated polystyrene in step a. In the propylene solution, 0.43 parts of initiator azobisisobutyronitrile are added to the grafting liquid prepared by the b process, and then the grafting liquid is added to the constant pressure dropping funnel for subsequent use;

[0056] d) Introduce nitrogen gas into the chlorinated polypropylene liquid containing the initiato...

Embodiment 3

[0059] Preparation of modified chlorinated polypropylene:

[0060] a) Add 25 parts of chlorinated polypropylene with a chlorine content of 20% to 40% to 62 parts of toluene, heat up to 70-80°C to completely dissolve the material, and obtain a chlorinated polypropylene liquid;

[0061] b) Dissolving 2.5 parts of methyl methacrylate and 5 parts of ethyl acrylate with 12 parts of toluene to obtain a mixed monomer liquid as a grafting liquid;

[0062] c) Accurately 0.75 parts of initiator dibenzoyl peroxide BPO, 0.25 parts of the weighed initiator is dissolved with 2 parts of toluene, added to the dissolved chlorinated polypropylene solution of a process, and then 0.50 parts The initiator is added to the grafting liquid prepared in step b, and then the grafting liquid is added to the constant pressure dropping funnel for subsequent use;

[0063] d) Introduce nitrogen gas into the chlorinated polypropylene liquid containing the initiator, wait until the temperature rises to 110°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com