Measuring device and measuring method for measuring gas permeability of material

A material gas and measurement device technology, applied in the direction of measurement devices, permeability/surface area analysis, material analysis, etc., can solve the problems of small partial pressure, inability to measure the partial pressure of the measured gas, and inability to measure the permeability, etc., to achieve Effect of Improving Sensitivity of Permeability Measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

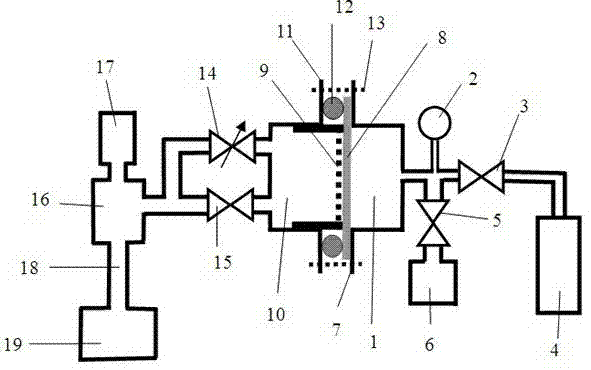

[0046] according to figure 1 A measuring device is constructed, and the material film to be measured is placed between the gas chamber and the gas accumulation chamber, and a vacuum rubber sealing ring is arranged between the material film to be measured and the flange of the gas accumulation chamber. The sealing flange of the gas chamber and the sealing flange of the gas accumulation chamber are connected and pressed by fastening bolts to realize the high vacuum seal between the film of the material to be tested and the flange of the gas accumulation chamber, and the method of the film of the material to be measured and the gas chamber low vacuum seal between the flanges. A supporting net is arranged between the gas accumulation chamber and the material film to be tested to support the material film to be tested. A needle valve and a bypass valve are arranged in parallel between the gas accumulation chamber and the high vacuum chamber. The high vacuum chamber is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com