Polyacrylate/nanometer ZnO composite finishing agent and preparation method thereof

A polyacrylate and acrylate technology, which is applied in the field of polyacrylate/nano ZnO composite finishing agent and its preparation, can solve the problems of water resistance and poor sanitation performance, and achieve improved water resistance, good thermal stability, and better performance in large surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

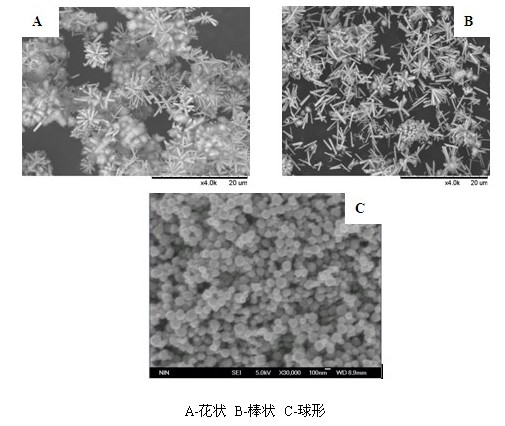

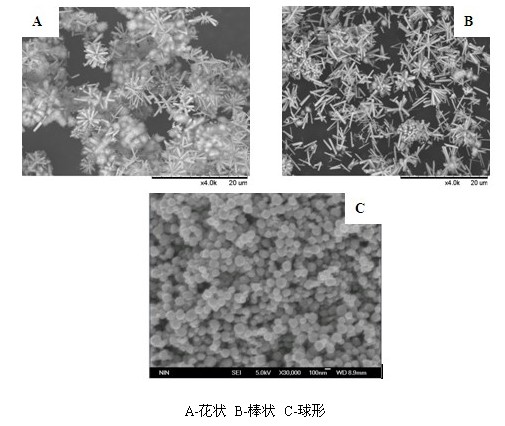

[0024] Adjust the pH of the aqueous solution containing 2wt% polyacrylic acid to 6, add 0.5wt% spherical nano-ZnO powder therein, magnetically stir for 10 minutes, ultrasonically for 10 minutes, then add 4 wt% surfactant sodium lauryl sulfate and stir evenly; The solution was transferred into a three-necked flask, heated to 58°C in a water bath, stirred for 20 minutes, and 1 / 3 of mixed monomers of butyl acrylate and methyl methacrylate were added (the mixed monomers accounted for 22 wt% of the total mass of the system, and the two monomers The molar ratio is 3:2), and the temperature was raised to 70°C for 30 minutes; the remaining mixed monomers and 0.5wt% ammonium persulfate aqueous solution were added dropwise, and after the addition was completed, the temperature was raised to 80°C for 2 hours; Ammonia solution to adjust the pH of the emulsion to 6 to obtain a nanocomposite coating agent.

Embodiment 2

[0026] Adjust the pH of the aqueous solution containing 0.6wt% polymethacrylic acid to 5.5, add 0.6wt% flower-shaped nano-ZnO powder to it, stir magnetically for 10 minutes, ultrasonicate for 10 minutes, and then add 2 wt% mixed surfactant sodium lauryl sulfate , Alkylphenol ether sulfosuccinate sodium salt (the mass ratio of the two surfactants is 1:1) and stir evenly; transfer the above solution into a three-necked flask, heat it in a water bath to 60°C, stir for 20min, add 1 / 4 The mixed monomer of ethyl acrylate and methyl methacrylate (the mixed monomer accounts for 25 wt% of the total mass of the system, and the molar ratio of the two monomers is 3:2), the temperature is raised to 73°C for 30min; After the remaining mixed monomers and 0.7wt% ammonium persulfate aqueous solution were added dropwise, the temperature was raised to 80°C for 2 hours of heat preservation reaction; ammonia aqueous solution was added at room temperature, and the pH of the emulsion was adjusted to ...

Embodiment 3

[0028] Adjust the pH of the aqueous solution containing 3wt% polyacrylamide to 5, add 1.5wt% rod-shaped nano-ZnO powder into it, stir magnetically for 10 minutes, ultrasonicate for 10 minutes, then add 3 wt% surfactant sodium dodecylbenzene sulfonate and stir evenly ; Move the above solution into a three-necked flask, heat it in a water bath to 60°C, stir for 20 minutes, add 1 / 3 of the mixed monomer of butyl acrylate and butyl methacrylate (the mixed monomer accounts for 24 wt% of the total mass of the system, two The molar ratio of the two monomers is 1:1), and the temperature was raised to 72°C for 30 minutes; the remaining mixed monomers and 0.6wt% potassium persulfate aqueous solution were added dropwise, and after the addition was completed, the temperature was raised to 82°C for 2 hours; Ammonia solution is added at room temperature to adjust the pH of the emulsion to 6 to obtain a nanocomposite coating agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com