Acrylic ester polymer, preparation method and application thereof, acrylic ester polymer coating and application thereof

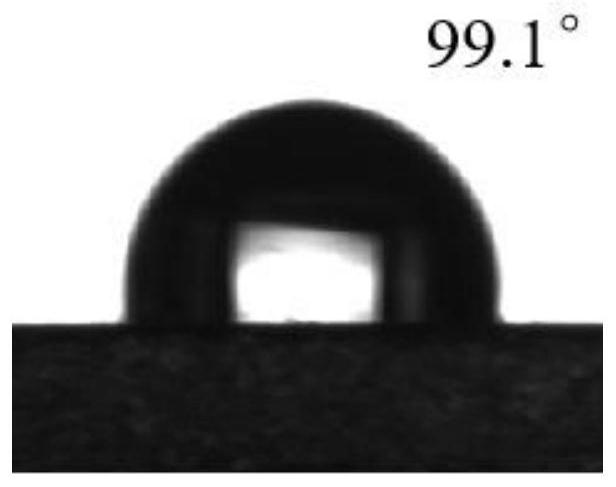

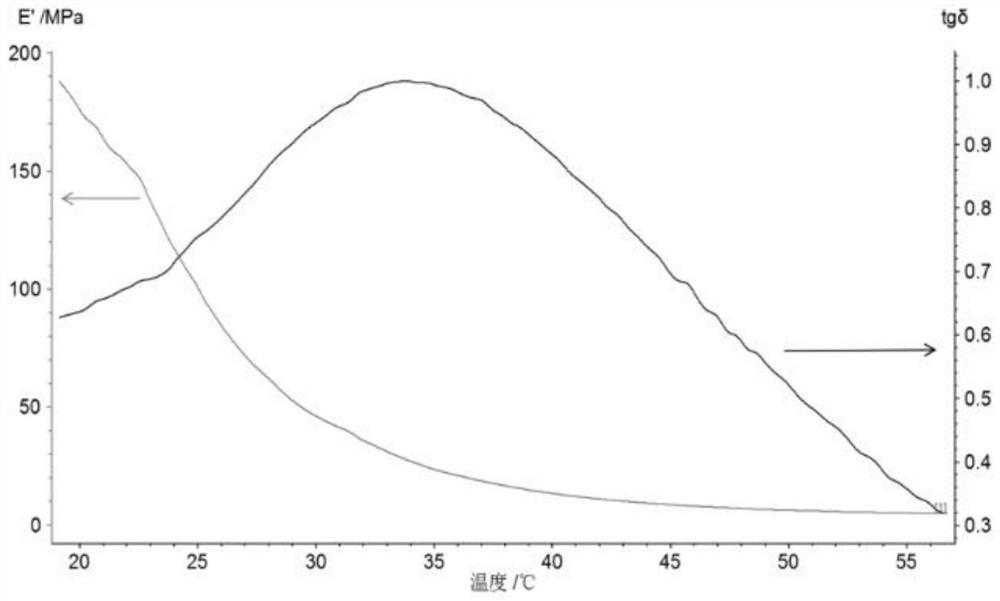

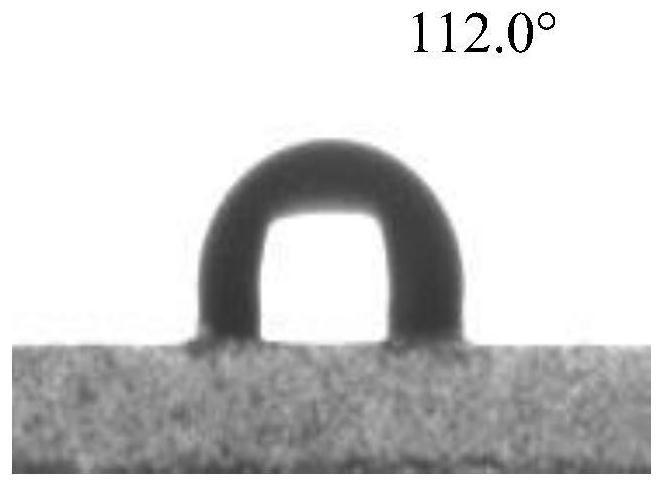

An acrylate and polymer technology, applied in the polymer field, can solve the problem of poor hydrophobicity of porous materials, achieve the effects of excellent hydrophobicity and air permeability, improve material strength, and improve hot stickiness and cold brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides the preparation method of the acrylate polymer described in the above technical scheme, comprising the following steps:

[0045] Mixing the first part of mixed monomers and the first initiator for prepolymerization to obtain a prepolymer, the first part of mixed monomers includes a first silane monomer, a first acrylate monomer and a first crosslinking agent;

[0046] The prepolymer, the second part of mixed monomers and the second initiator are mixed for polymerization reaction to obtain an acrylic polymer; the second part of mixed monomers includes a second silane monomer, a second acrylic monomer body and a second crosslinking agent;

[0047] The first silane monomer and the second silane monomer independently include monovinyl-terminated polydimethylsiloxane, vinylmethyl bis(dimethylpolysiloxane) silane, methacryloyl Oxypropyltris(trimethylsiloxy)silane, 1-methoxy-1-(trimethylsiloxy)-2-methyl-1-propene, vinyloxytrimethylsilane, ethyle...

Embodiment 1

[0074] Place methyl methacrylate, 2-ethylhexyl acrylate, vinyloxytrimethylsilane, vinylmethylsiloxane-dimethylsiloxane in sodium hydroxide with a concentration of 2mol / L Fully mix the solution at room temperature to remove the polymerization inhibitor, discard the water phase, then add anhydrous calcium chloride to the organic phase containing the monomer, dry for 6 hours, filter, and set aside; use absolute ethanol to recrystallize AIBN After 2-3 times, let it dry naturally at room temperature for 24 hours, and store it at low temperature for later use.

[0075] Mix 30g of methyl methacrylate, 15g of 2-ethylhexyl acrylate, 40g of vinyloxytrimethylsilane, 15g of vinylmethylsiloxane-dimethylsiloxane and 0.5g of 1,6-hexane Diol diacrylate is mixed evenly to obtain mixed monomers;

[0076] Add 0.275g AIBN and 100g ethyl acetate into a three-necked flask, stir and mix for 15min at 80°C, add 15g of mixed monomers, and prepolymerize at 80°C for 30min to obtain a prepolymer;

[007...

Embodiment 2

[0079] Methyl methacrylate, ethyl acrylate, lauryl methacrylate, and methacryloxypropyl tris(trimethylsiloxane)silane were respectively placed in a sodium hydroxide solution with a concentration of 1.2mol / L After fully shaking, let it stand for phase separation, discard the water phase to remove the polymerization inhibitor, then add anhydrous calcium chloride to the obtained organic phase, dry it for 6 hours, filter it, and set aside; use absolute ethanol to recrystallize AIBN for 2 to 3 After the second time, let it dry naturally at room temperature for 24 hours, and store it at low temperature for later use.

[0080] 40 g methyl methacrylate, 10 g ethyl acrylate, 5 g lauryl methacrylate, 30 g methacryloxypropyl tris(trimethylsiloxane) silane and 0.3 g propoxylated trimethylolpropane tris Acrylic esters are mixed evenly to obtain mixed monomers;

[0081] Add 0.365g AIBN and 80g ethyl acetate into a three-necked flask, stir and mix at 80°C for 15 minutes, add 20g of mixed mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com